Manual safe sampling device

A sampling device and safe technology, applied in the field of manual safety sampling devices, can solve the problems of cumbersome operation and large sampling deviation, and achieve the effect of simple operation, low manufacturing cost and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

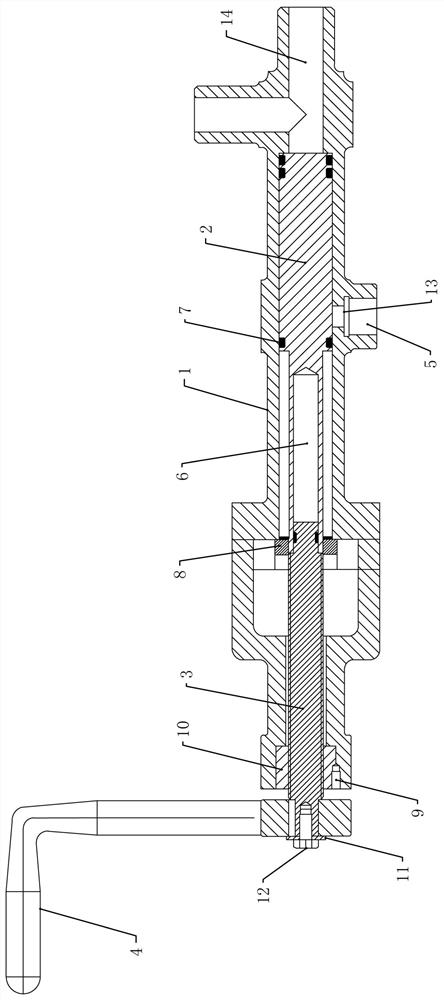

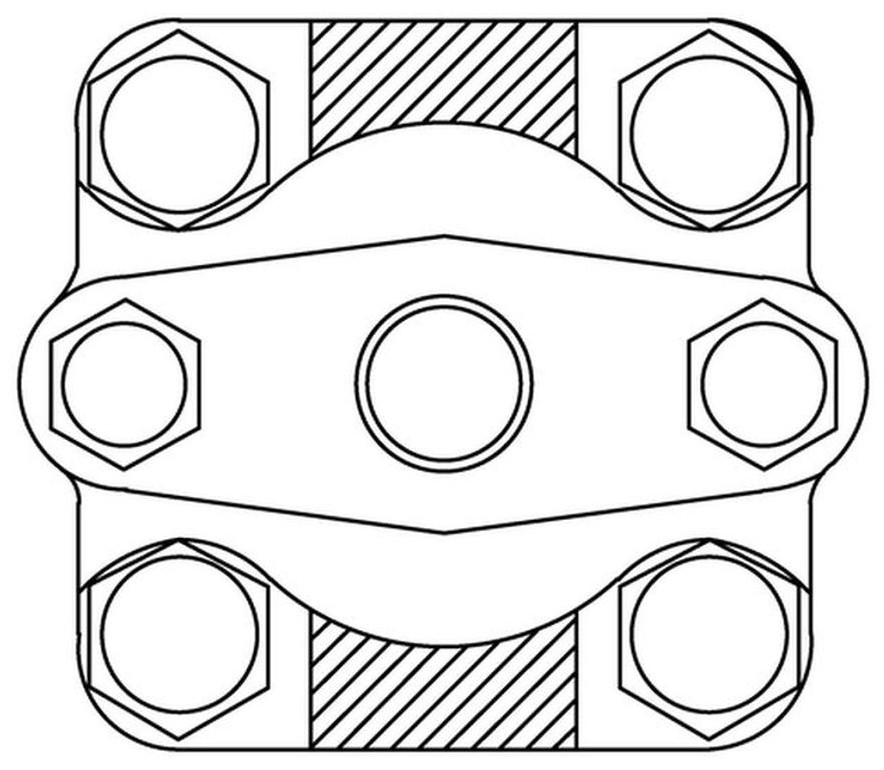

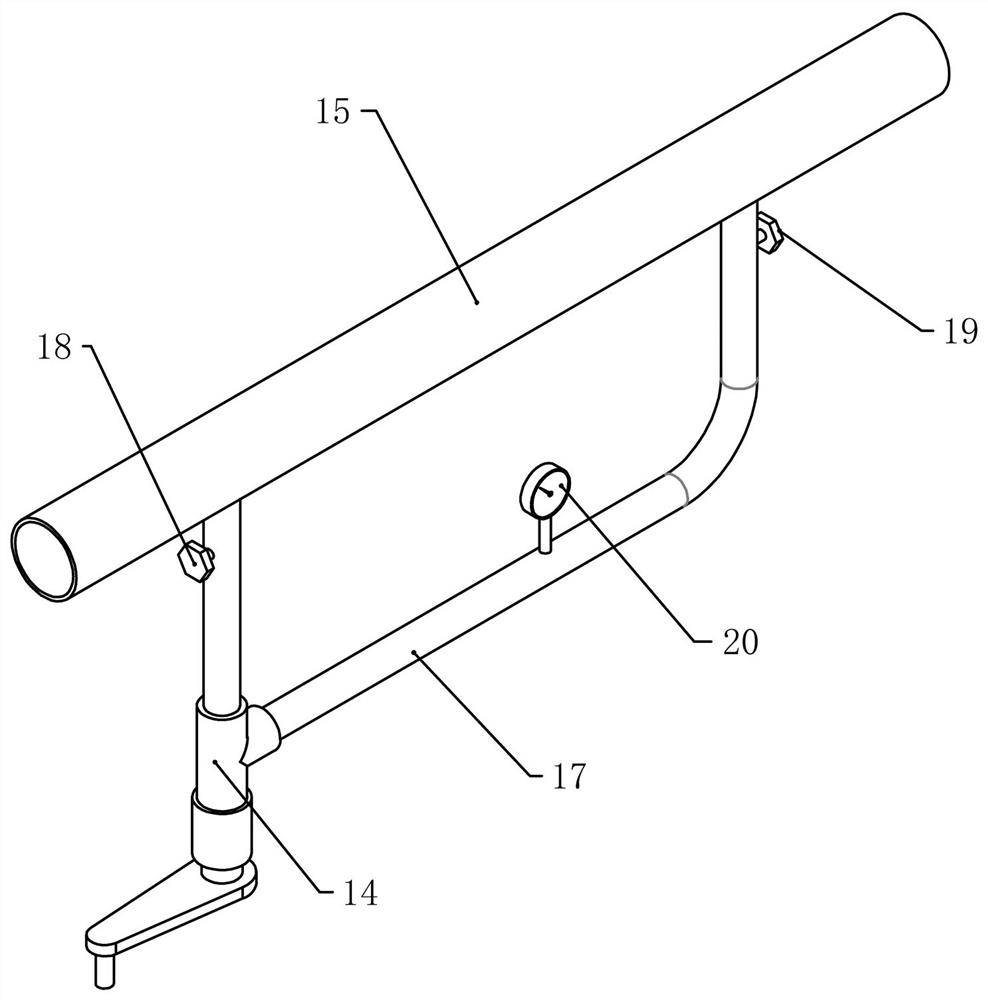

[0030] Embodiment 1. The present invention is a manual safety sampling device, which includes a horizontal device cavity 1. The interior of the device cavity 1 is a cavity with openings at both ends. Pistons are installed in the device cavity 1 from right to left. 2 and the screw 3, the piston 2 can slide laterally in the device cavity 1, the piston 3 and the inner wall of the device cavity 1 are sealed and airtight, the piston 2 is connected to the screw 3 in rotation, and the screw 3 is connected to the device cavity 1 The screw rod 3 is threaded so that when the screw rod 3 is turned, the screw rod 3 can move. At this time, the screw rod 3 pulls the piston 2 to move laterally. A handle 4 is fixed at the end of the screw rod 3, and the handle 4 is placed outside the device cavity 1. It is convenient to rotate the screw rod 3, and a sampling hole 5 is provided on the cavity outer wall at the end of the left end of the piston 2, so that in the initial position, the sampling hol...

Embodiment 2

[0032] Embodiment 2, in order to better pull the piston 2 to move, a thrust rod 6 is connected between the piston 2 and the screw rod 3, and the thrust rod 6 is fixedly connected to the piston 2. For example, during installation, the thrust rod 6 is fixedly inserted into the piston 2 Inside, while the screw rod 3 and the thrust rod 6 are connected in rotation. When the screw rod 3 rotates, the thrust rod 6 does not rotate, but the thrust rod 6 and the piston 2 move laterally.

Embodiment 3

[0033] Embodiment 3, in order to prevent the industrial medium from leaking from the gap between the piston 2 and the inner wall of the cavity, multiple sets of sealing rings 7 are arranged at both ends of the piston 2 or the inner wall of the cavity to ensure that the piston 2 is stationary and moving. It can be sealed to prevent leakage of industrial media.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com