Continuous beam cantilever casting secondary real-time counterweight system and construction method

A cantilever and poured technology, which is applied in the continuous beam cantilever pouring secondary real-time counterweight system and construction field, can solve the problems of high artificial uncertainty and risk, reduce labor intensity, reduce the number of switching times, and reduce imbalance The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

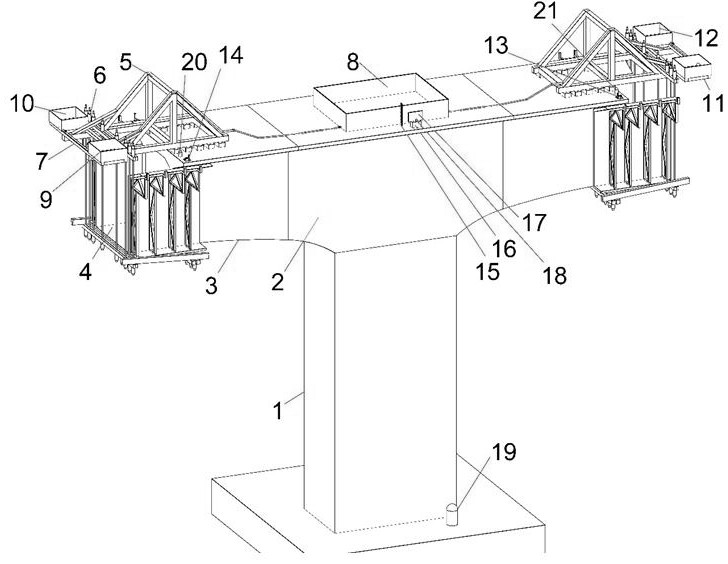

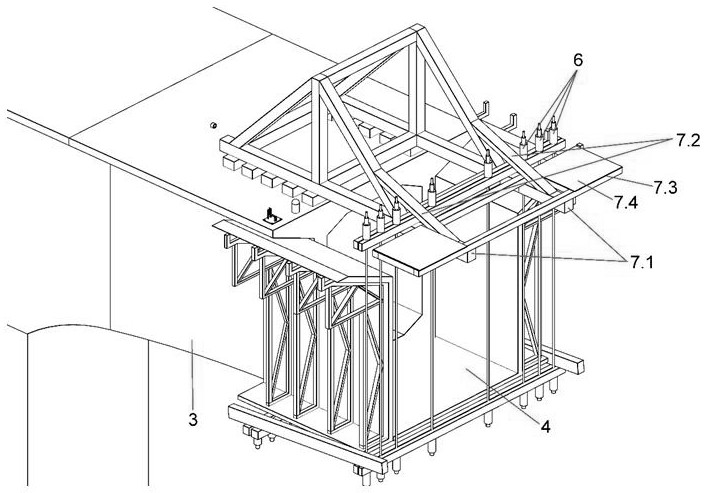

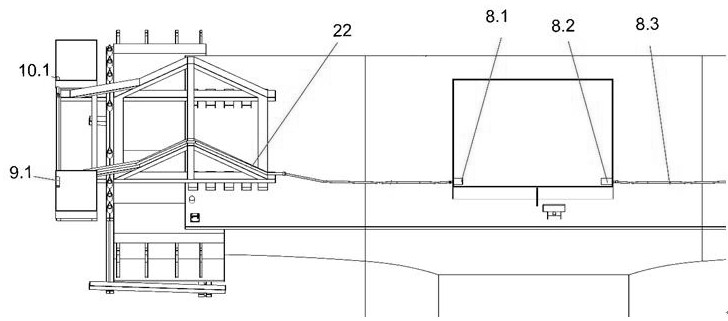

[0048] as attached figure 1 ~ attached Figure 8 As shown in this structure diagram, the present invention refits the hanging basket on the basis of the existing bridge pier 1, 0# section 2, the poured section 3, the pouring section 4, the hanging basket 5, the sling and the formwork load-bearing system 6, and then adds Water tank and other auxiliary devices, specifically including hanging basket modification part 7, central water tank 8, water tank I to be poured left 9, water tank I to be poured right 10, water tank to be poured right to build section II left 11, water tank to be poured II right 12. Adjustable laser emitting device II13, adjustable laser emitting device I14, double-sided photosensitive sensing device 15, main controller 16, display screen 17, sound and light alarm I18, sound and light alarm II19, sound and light alarm III20, Sound and light alarm IV21, water tank supervisor 22, supervisor electric control valve 23, horizontal pipe electric control valve 24,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com