A control method of clothes treatment equipment

A technology of clothing processing equipment and control method, which is applied to the control device of washing machine, other washing machines, textiles and paper making, etc., can solve the problem of inconvenient opening and closing of the inner cylinder door, and achieve the effect of improving user experience and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

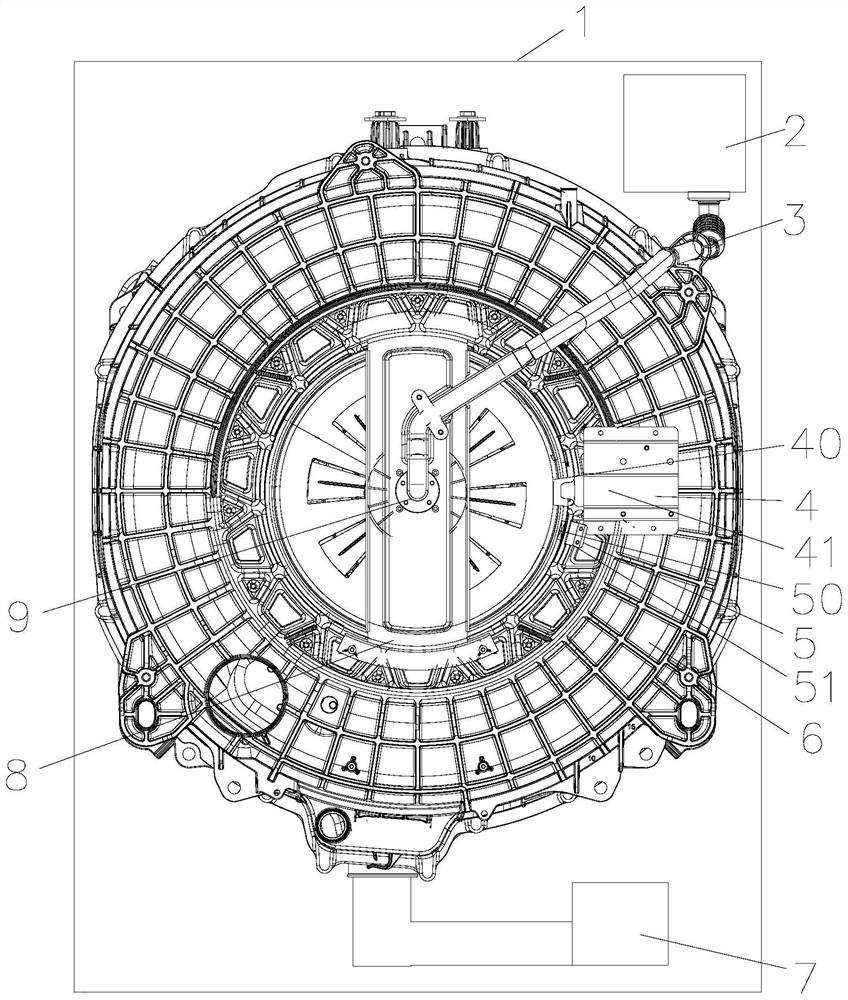

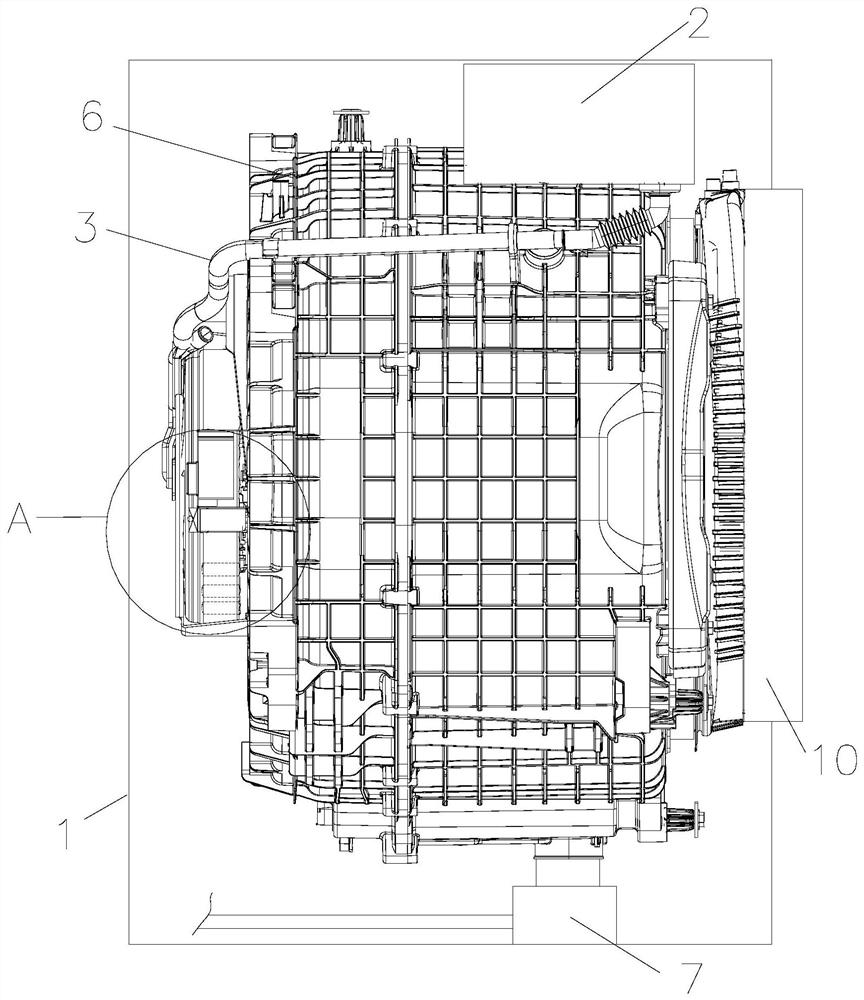

[0049]This example describes a drum washing machine, including an outer cylinder 6, rotatably in an inner cylinder inside the outer cylinder 6, and an inner cylinder is provided, an open position, an open, a departure opening and an open phase. The overlapping setting is installed on the inner cylinder, and the inner tube door corresponding to the closure exit is mounted. The inner tube is provided with an operation portion for locking the inner barrel; the washing machine also includes: a detecting mechanism 5 for detecting the operation unit on the inner door Whether the position is convenient to open and close the inner tube; the control mechanism, the detection mechanism 5 is connected to the control mechanism for easy opening and closing the inner cylindrical door after detecting the position of the operating portion on the inner tube door.

[0050]The inner cylinder is easy to open and closes by the arrangement of the inner cylinder, and the inner tube door is in line with the hu...

Embodiment 2

[0054]SeeFigure 1-3In the present embodiment, one side of the inner cylinder door is applied to the mounting structure of the inner cylindrical door flipping and closing on the inner tube, and the other side of the setting is provided with an operation portion; the detecting mechanism 5 passes whether the operation unit is The horizontal line of the inner tube door is detected whether the position on the inner tube door is convenient to open and close.

[0055]The present invention ensures that the inner cylinder is easy to open when the inner cylinder stops rotation. Specifically, when the inner tube is stationary, the mounting structure is disposed on the left or right side, and the operation portion is disposed on the right or left, and the position of the operating portion on the inner door is convenient to open and close the inner tube door, that is, detects The mechanism 5 detects whether the operation unit is set to the right or left.

Embodiment 3

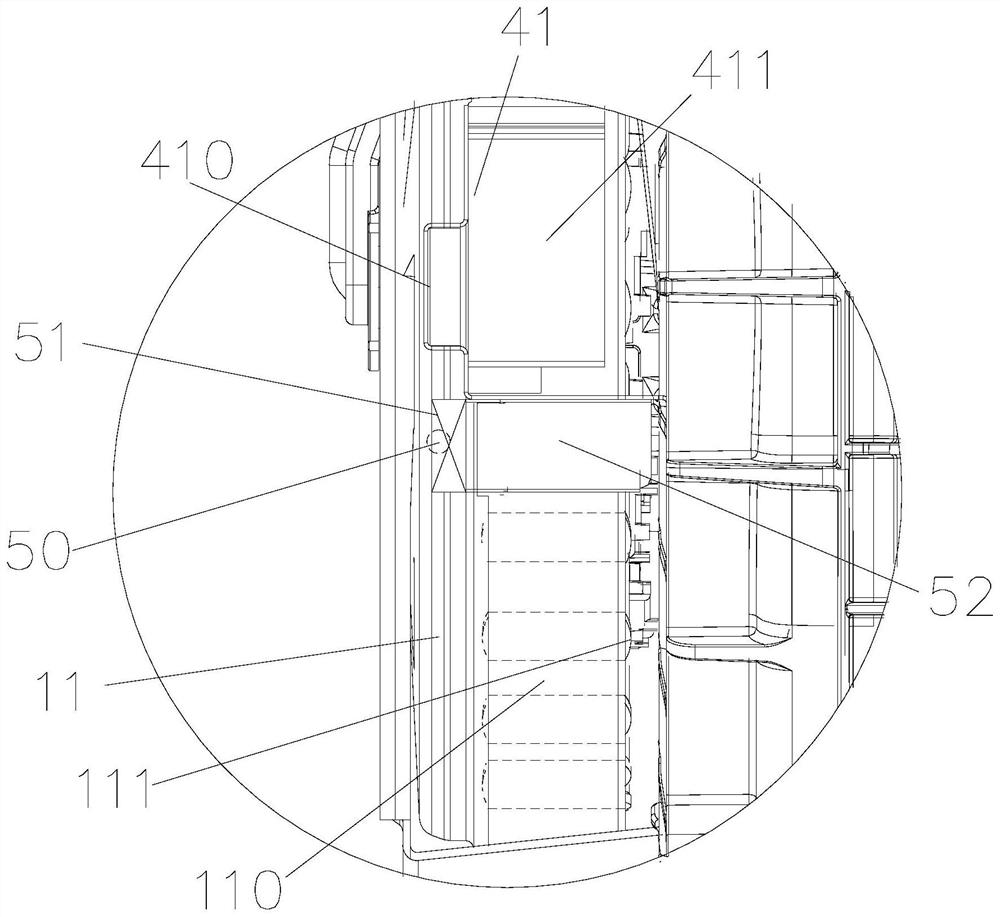

[0057]SeeFigure 1-3In this embodiment, the detecting mechanism 5 includes: the transmitting member 50, rotates synchronously with the operating portion, for transmitting signals; the receiver 51, when the position of the operating portion is convenient to the inner tube door and the transmitter 50 Relatively, the receiver 51 is coupled to the control mechanism for transmitting the signal to the control mechanism after receiving the signal indicating that the transmitting member 50 is disposed with the receiver 51.

[0058]The present invention achieves whether or not the position on the operating portion on the inner tube door is easily detected by the arrangement. Specifically, the transmitting member 50 transmits the signal, the receiver 51 receives the signal and transmits the signal to the control mechanism, and the control mechanism compares the signal and the preset, the position of the operation unit on the inner tube door is convenient to open and close the inner door. , Determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com