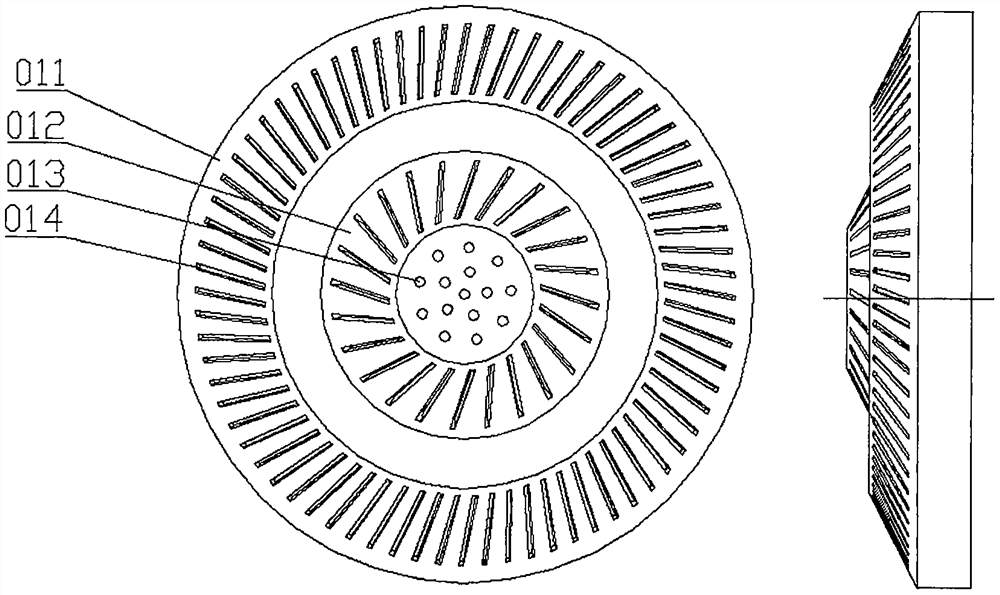

Annular air knife for cleaning inner wall of material container barrel

A technology of container barrel and annular air, which is applied in the field of dust removal and cleaning, and water removal on plane or cylinder, and can solve the problems affecting the health of on-site operators, short service life, high noise level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

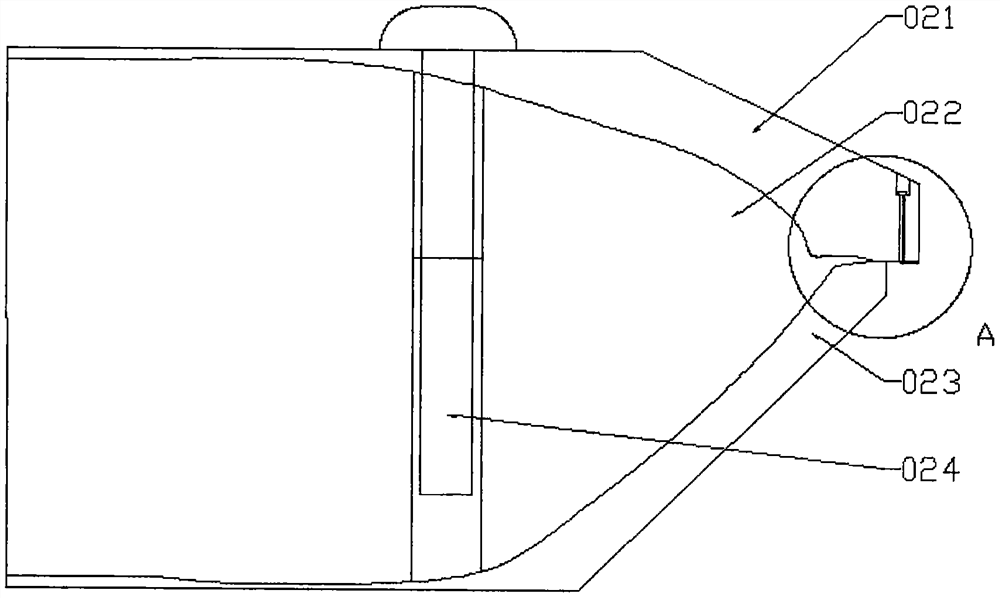

Embodiment 1

[0037] When the inside of the bucket needs to be cleaned, extend the air knife into the inside of the inverted bucket, and stop when the top of the air knife is close to the bottom of the bucket. At this time, the compressed air is injected for 10 seconds, and the dust removal and blowing of the bottom of the bucket is carried out by the air nozzle 010. After 10 seconds, slowly recover the air knife at a certain speed, because the impact air curtain of the annular air knife 020 is inclined downward, so the moisture and dust adhering to the bottom of the bucket will be under the high-intensity and large-scale air curtain It is continuously sent down, and finally sent out of the mouth of the barrel; at this time, the compressed air can be turned off, wait for the next barrel, then send the air knife to the bottom of the barrel and turn on the compressed air, and repeat the process; if the moisture and When the dust is difficult to clean, you can choose the appropriate air volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com