Turbine rotor small shaft disc grinding tool

A steam turbine rotor and disk grinding technology, which is applied in the direction of grinding tools, etc., can solve problems affecting the accuracy of thermal measurement values, hidden dangers of unit safe operation, and mechanical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

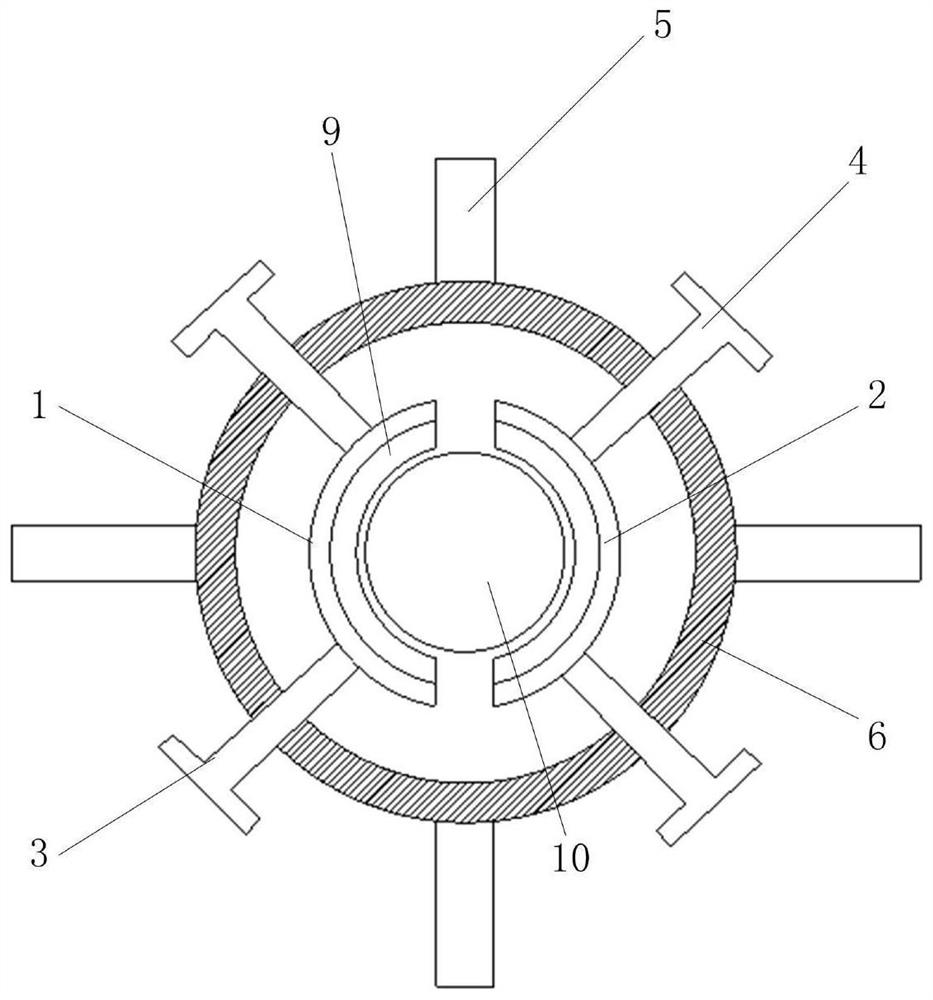

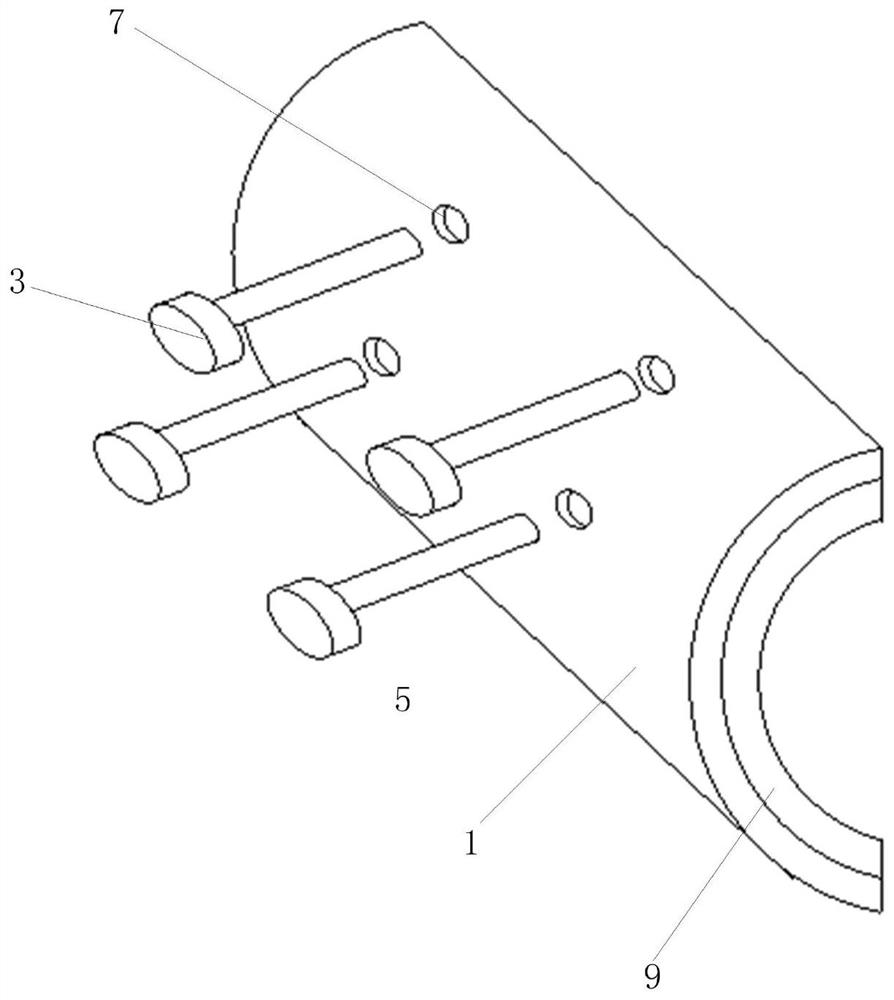

[0024] See Figure 1-Figure 3 , the embodiment of the present invention provides a disc grinding tool for the small shaft of a steam turbine rotor 10, including: a first arc-shaped grinding block 1, a second arc-shaped grinding block 2, a first top wire 3, a second top wire 4, a handle 5, the sleeve 6; the first arc-shaped grinding block 1, the second arc-shaped grinding block 2 are combined to form a circle, and the size of the circle is a predetermined size; in the first arc-shaped grinding block The outer wall of 1 is provided with a first groove 7 adapted to the end of the first top wire 3, the first top wire 3 passes through the sleeve 6, and the end of the first top wire 3 The top is connected to the inside of the first groove 7; on the outer wall of the second arc-shaped grinding block 2, there is a second groove 8 adapted to the end of the second top wire 4, so The second top wire 4 passes through the sleeve 6, and the end of the second top wire 4 abuts against the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com