Full-automatic parcel importing and loading control method

A control method and fully automatic technology, applied in sorting and other directions, can solve the problems of difficult to improve sorting efficiency, low scanning efficiency, low processing speed, etc., to improve speed and accuracy, solve operating pressure, and ensure high-speed operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

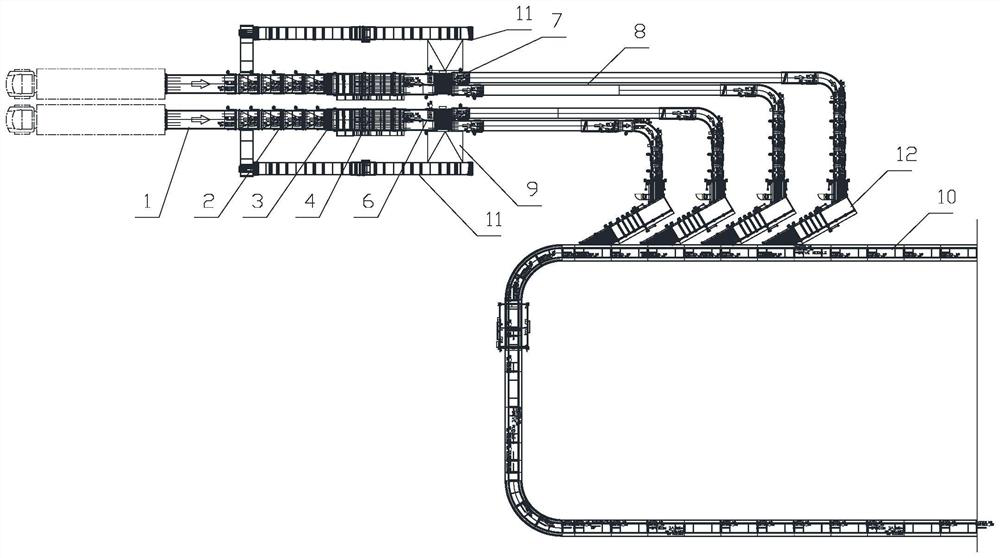

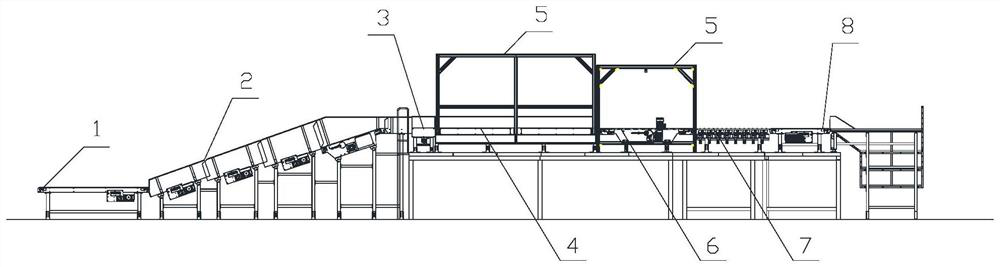

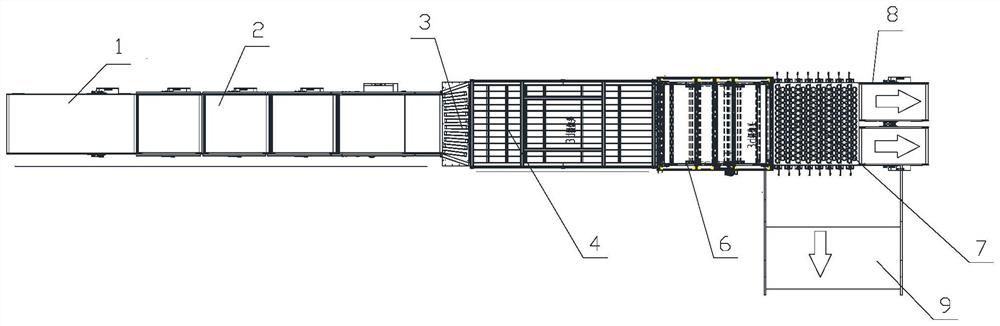

[0041] Example 1, such as figure 1 As shown, at the front end of the cross-belt sorter 10, two sets of fully automatic package loading devices described in this application are arranged in parallel along the conveying direction. Each group of fully automatic importing and loading devices is equipped with an on-line conveying device 1, a 1-degree slope separating device 2, a scattering separating device 3, a single piece separating device 4, a visual recognition device 5, a recognition conveyor belt conveyor 6, and a balance wheel pointing device connected in sequence. Picking machine 7, diverting belt conveyor 8, chute 9, return conveyor 11 and introduction device 12.

[0042]Wherein, the on-line conveying device 1 is directly connected to the unloading end, that is, the on-line conveying device 1 can directly dock with the truck, and the piles of packages unloaded from the transport vehicle are directly placed on the on-line conveying device 1 . The upper line conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com