Hinge of inward tilt-turn window and inward tilt-turn window

A technology of hinges and inverted windows, applied in the field of doors and windows, can solve problems such as insufficient support strength, and achieve the effects of small torque, good bearing performance, and high support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

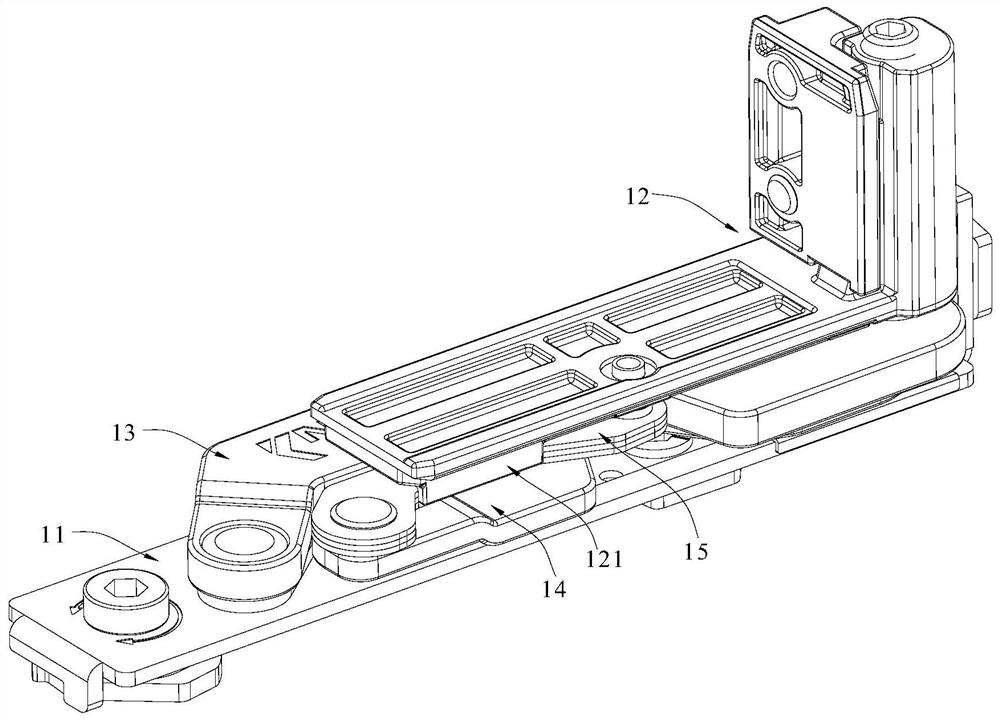

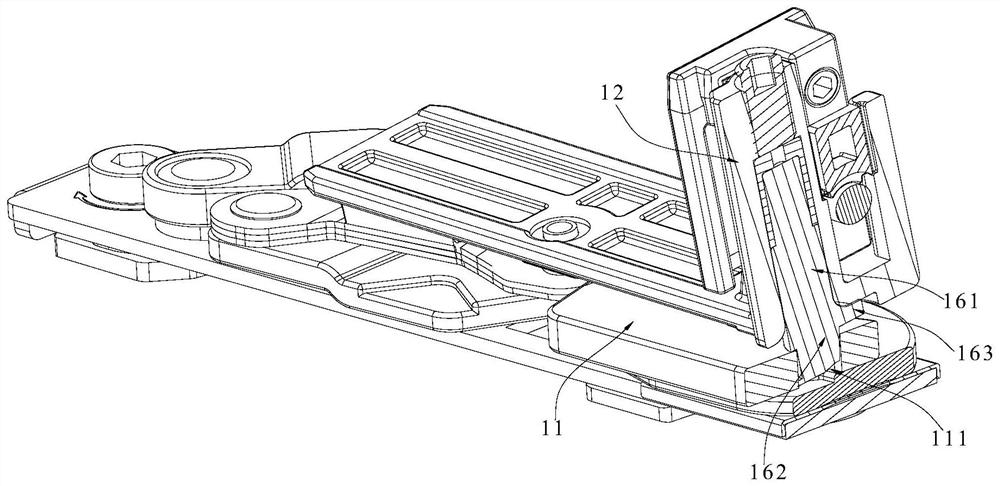

[0039] Such as figure 1 The hinge 10 shown in -8 includes the first hinge seat 11, the second hinge seat 12, the first hinge piece 13, the second hinge piece 14, the elastic member 15 and the inner turning piece, specifically the first hinge One end of the piece 13 is hinged on the first hinge seat 11 and forms a first hinge end, and the other end of the first hinge piece 13 is hinged on the second hinge seat 12 .

[0040] In addition, one end of the second hinged piece 14 is hinged on the first hinged seat 11 and is formed as a second hinged end, and the other end of the second hinged piece 14 is hinged with one end of the elastic member 15; The second hinged seat 12 is formed as a third hinged end. Moreover, the first hinged piece 13 and the second hinged piece 14 are cross-hinged, and the first hinged end and the second hinged end are arranged at intervals. In addition, the second hinged seat 12 can also rotate inward with the third hinged end as a fulcrum.

[0041] One e...

Embodiment 2

[0057] Such as figure 1 The inward-opening window shown in -11 includes an outer frame 20, an inner frame 30, and the above-mentioned hinge 10, and the hinge 10 includes a first hinge seat 11, a second hinge seat 12, a first hinge piece 13, and a second hinge piece 14 , the elastic part 15 and the inner inverted part, specifically, one end of the first hinged piece 13 is hinged on the first hinged seat 11 and is formed as a first hinged end, while the other end of the first hinged piece 13 is hinged on the second hinged seat 12 .

[0058] In addition, one end of the second hinged piece 14 is hinged on the first hinged seat 11 and is formed as a second hinged end, and the other end of the second hinged piece 14 is hinged with one end of the elastic member 15; The second hinged seat 12 is formed as a third hinged end. Moreover, the first hinged piece 13 and the second hinged piece 14 are cross-hinged, and the first hinged end and the second hinged end are arranged at intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com