Overhang structure support system

A technology for structural support and support rods, which is applied to pillars, building structures, and on-site preparation of building components, and can solve problems such as inconvenient installation and removal processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-4 The application is described in further detail.

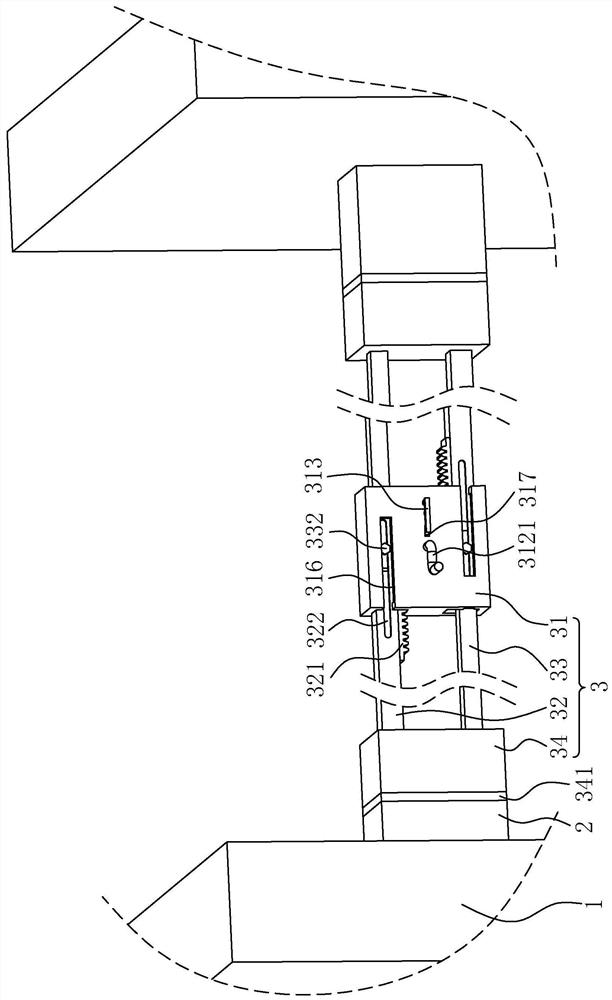

[0038] The embodiment of the present application discloses a support system for a cantilever structure. refer to figure 1 , a support system for a cantilevered structure includes two support columns 1 respectively arranged on both sides of the main body of the building. Cantilever beams 2 are fixedly arranged on the sides where the two support columns 1 are close to each other. Between the two cantilever beams 2 A support assembly 3 is provided.

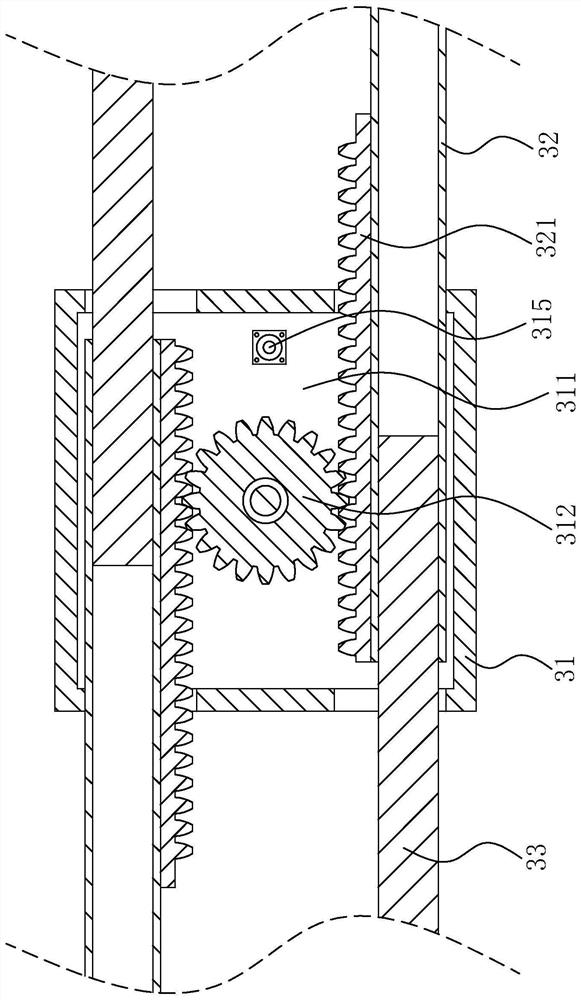

[0039] refer to figure 1 and figure 2, the supporting assembly 3 includes a fixed block 31, a supporting rod 32, a reinforcing rod 33 and an abutting block 34, and the length directions of the fixing block 31, the supporting rod 32 and the reinforcing rod 33 are the directions in which the two cantilever beams 2 approach or move away from each other , there are two supporting rods 32, reinforcing rods 33 and pressing blocks, and they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com