Water network zone lime solidified soil test section filling design method

A design method and technology of test sections, applied in construction, soil protection, infrastructure engineering, etc., can solve problems such as difficult construction water stability of the subgrade layer, reduce uneven subsidence of the subgrade, significant social and economic benefits, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

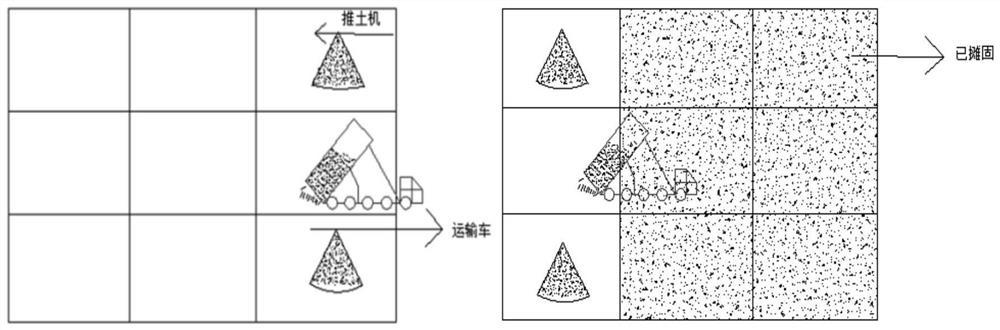

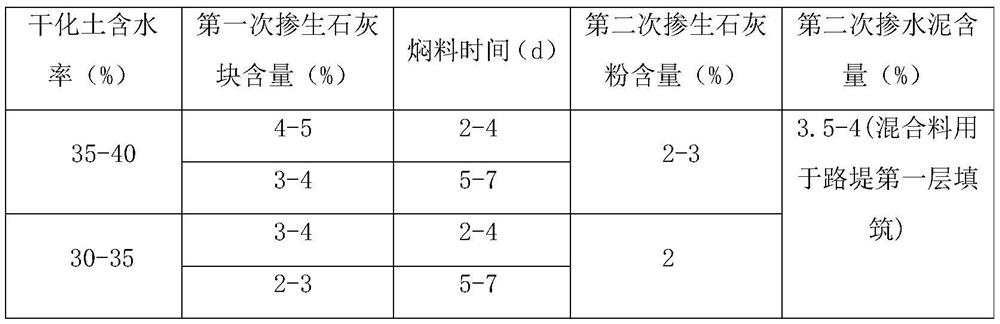

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

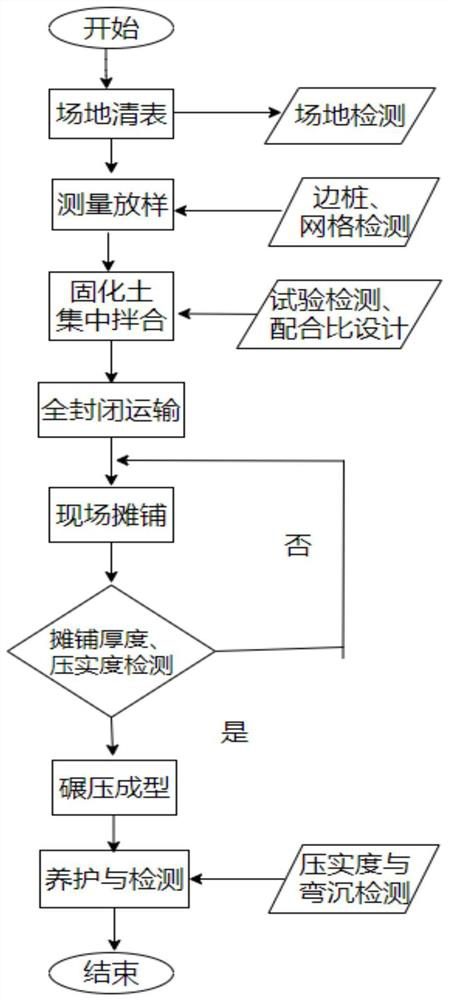

[0025] As an embodiment, the filling design method of the lime-solidified soil test section in the water network zone includes the following steps:

[0026] Step 1: Clear the site list. Select a typical section as the test section, and clean up the site according to the design requirements and roadbed construction technical specifications. Clean up the humus, topsoil, turf, etc. on the original ground surface within the width of the road, and dig out all the tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com