All-cotton double-color grey fabric and preparation method thereof

A color pattern and fabric technology, applied in the field of textiles, can solve the problems of inability to achieve two-color gray effect and high cost of cotton fabrics, achieve good visual impact effect, high production efficiency, and improve the effect of bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

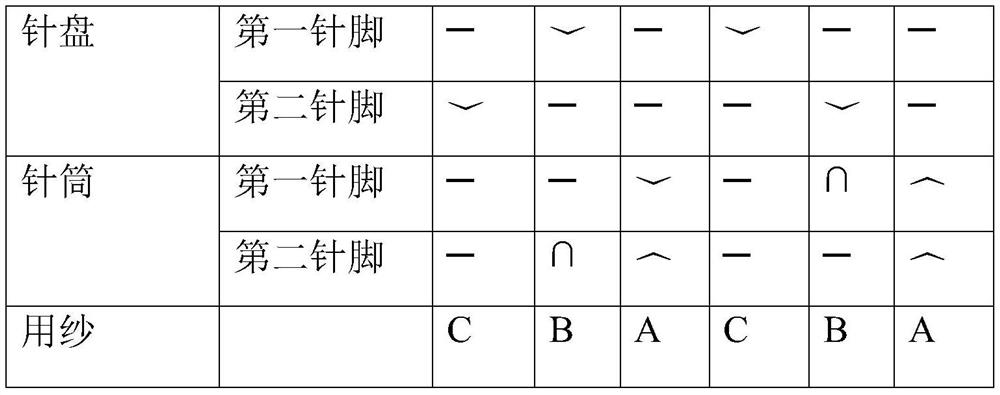

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing an all-cotton two-color gray fabric, comprising the steps of:

[0034] (1) adopt dyestuff to dye cotton;

[0035] (2) mixing dyed cotton with raw cotton to prepare full cotton yarn;

[0036] (3) process all-cotton yarn to make all-cotton gauze;

[0037] (4) scouring all cotton gauze;

[0038] (5) overflow dyeing is carried out to the all-cotton gauze through scouring, obtains all-cotton two-color gray fabric.

[0039] Further, in the step (1), the dyeing step specifically includes: immersing the cotton in a reactive dye solution, the reactive dye solution is added with sodium chloride and sodium carbonate, and is dyed at a temperature of 90°C.

[0040] Further, in the step (1), the reactive dye is a chloro-s-triazine reactive dye.

[0041] Further, in the step (1), the added concentration of sodium chloride is 60g / L, and the added concentration of sodium carbonate is 20g / L.

[0042] Further, in the step (1), the cotton is immersed in the reac...

Embodiment 2

[0053] A method for preparing an all-cotton two-color gray fabric, comprising the steps of:

[0054] (1) adopt dyestuff to dye cotton;

[0055] (2) mixing dyed cotton with raw cotton to prepare full cotton yarn;

[0056] (3) process all-cotton yarn to make all-cotton gauze;

[0057] (4) scouring all cotton gauze;

[0058] (5) overflow dyeing is carried out to the all-cotton gauze through scouring, obtains all-cotton two-color gray fabric.

[0059] Further, in the step (1), the dyeing step specifically includes: immersing the cotton in a reactive dye solution, the reactive dye solution is added with sodium chloride and sodium carbonate, and is dyed at a temperature of 88°C.

[0060] Further, in the step (1), the reactive dye is a chloro-s-triazine reactive dye.

[0061] Further, the added concentration of sodium chloride is 58g / L, and the added concentration of sodium carbonate is 18g / L.

[0062] Further, in the step (1), the cotton is immersed in the reactive dye solution...

Embodiment 3

[0070] A method for preparing an all-cotton two-color gray fabric, comprising the steps of:

[0071] (1) adopt dyestuff to dye cotton;

[0072] (2) mixing dyed cotton with raw cotton to prepare full cotton yarn;

[0073] (3) process all-cotton yarn to make all-cotton gauze;

[0074] (4) scouring all cotton gauze;

[0075] (5) overflow dyeing is carried out to the all-cotton gauze through scouring, obtains all-cotton two-color gray fabric.

[0076] Further, in the step (1), the dyeing step specifically includes: immersing the cotton in a reactive dye solution, the reactive dye solution is added with sodium chloride and sodium carbonate, and is dyed at a temperature of 92°C.

[0077] Further, in the step (1), the reactive dye is a chloro-s-triazine reactive dye.

[0078] Further, in the step (1), the added concentration of sodium chloride is 62g / L, and the added concentration of sodium carbonate is 22g / L.

[0079] Further, in the step (1), the cotton is immersed in the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com