A preparation device for gallium nitride thin film

A preparation device, gallium nitride technology, applied in metal material coating process, vacuum evaporation coating, coating, etc., can solve the problems of poor applicability, inconvenient fixing of film sample holders, etc., and achieve internal temperature stability and thermal insulation performance Good, good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

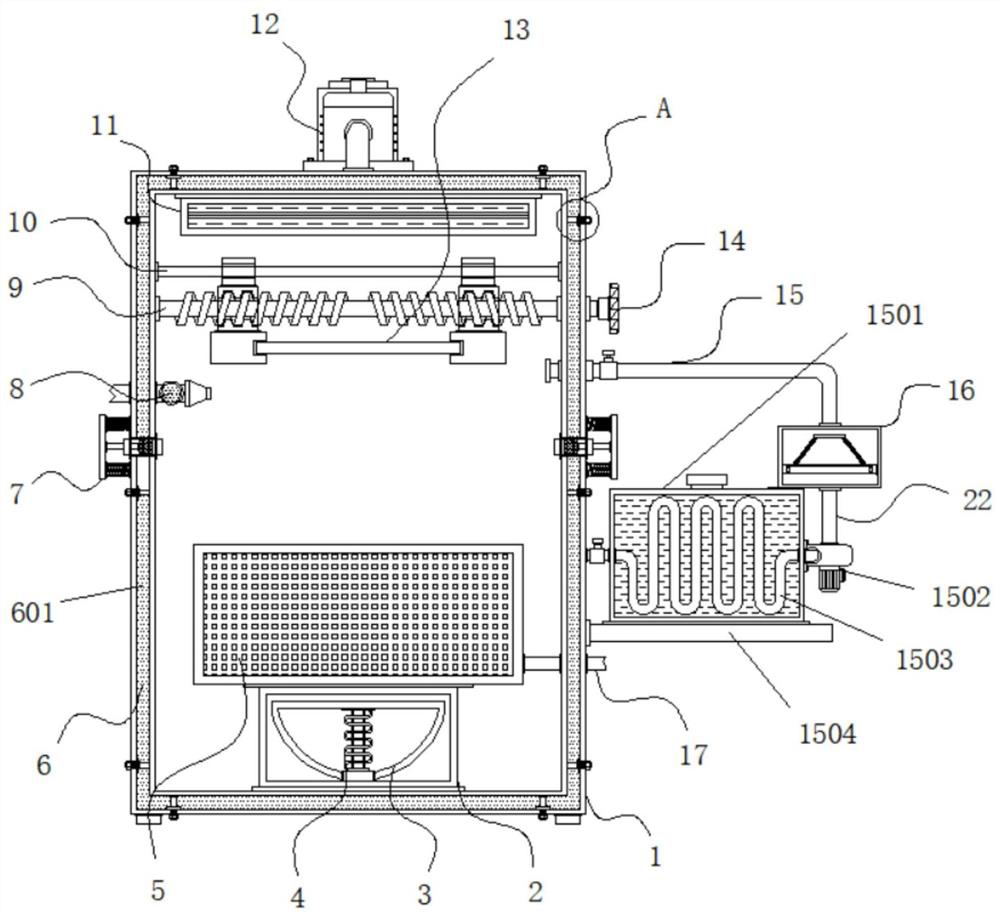

[0035] Example 1: See Figure 1-6, a preparation device for gallium nitride thin films, comprising a preparation chamber 1 and an evaporation chamber 2, the evaporation chamber 2 is fixedly connected to the bottom end of the preparation chamber 1, the interior of the evaporation chamber 2 is fixedly connected to a quartz crucible 3, and the quartz crucible 3 The inside is fixedly connected with a heating wire 4, the top of the evaporation chamber 2 is fixedly connected with an ionization chamber 5, the outer wall of the preparation chamber 1 is provided with a thermal insulation structure 6, and the two sides of the preparation chamber 1 are provided with an explosion-proof structure 7 near the top. One side inside the preparation chamber 1 is fixedly connected with a radio frequency ionization gun 8, and the middle position of the top of the preparation chamber 1 is fixedly connected with a vacuum pump 12. The model of the vacuum pump 12 can be 2BV-5110, and one side of the pr...

Embodiment 2

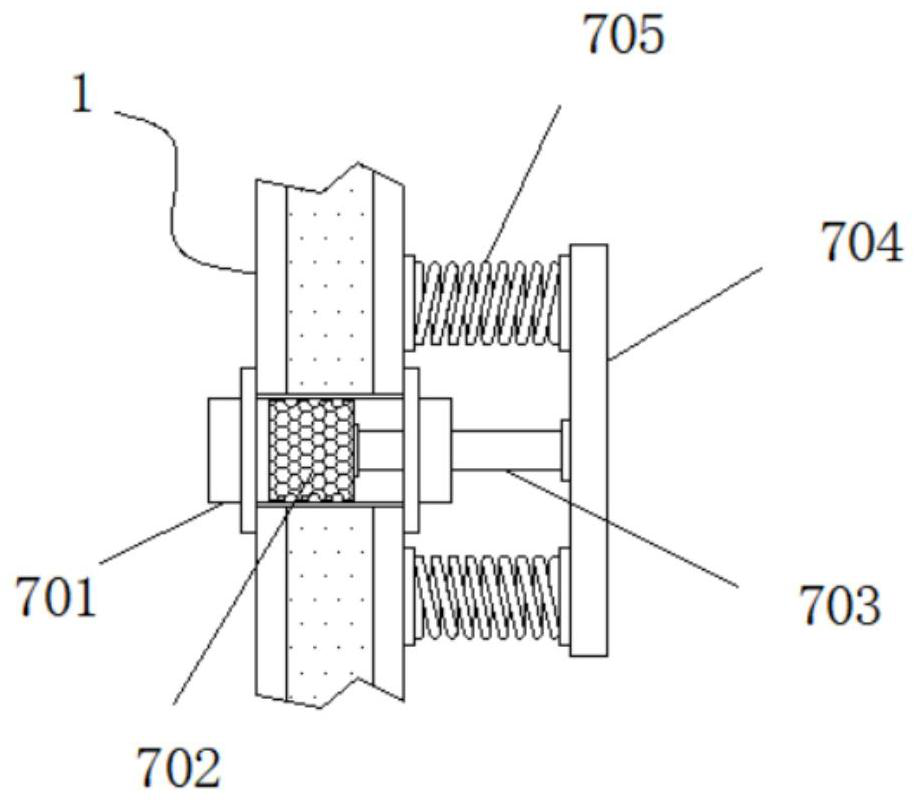

[0040] Embodiment 2: The thermal insulation structure 6 is composed of a cavity 601, a casing 602, a connecting rod 603, a nut 604, a through hole 605 and a thermal insulation rock wool 606. The casing 602 is arranged outside the preparation bin 1, between the casing 602 and the preparation bin 1 A cavity 601 is provided, and a plurality of sets of through holes 605 are arranged inside the shell 602. A plurality of sets of connecting rods 603 are fixedly connected to the outer wall of the preparation bin 1, one side of the connecting rods 603 runs through the through holes 605, and the outside of the connecting rods 603 One side is provided with a nut 604, and the interior of the cavity 601 is filled with thermal insulation rock wool 606;

[0041] The outside of one side of the connecting rod 603 is provided with threads, and there is a one-to-one correspondence between the connecting rod 603 and the through hole 605;

[0042] Specifically, such as figure 1 and Figure 4 As ...

Embodiment 3

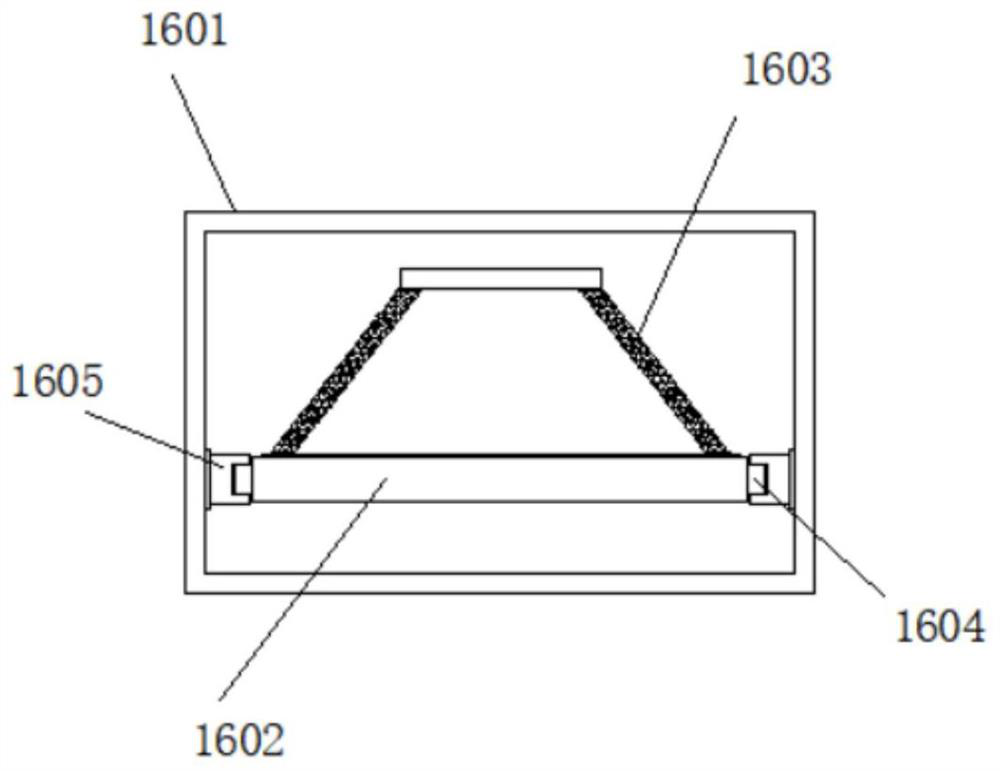

[0043] Embodiment 3: Explosion-proof structure 7 is made up of through pipe 701, piston 702, fixed rod 703, tension plate 704 and spring 705, and through pipe 701 is respectively arranged in the inside of preparation bin 1 both sides, and inside through pipe 701 is provided with piston 702, one side of the piston 702 is fixedly connected with a fixed rod 703, one side of the fixed rod 703 is fixedly connected with a tension plate 704, and a spring 705 is fixedly connected between the two ends of one side of the tension plate 704 and the preparation bin 1;

[0044] Specifically, such as figure 1 and image 3 As shown, when in use, if the pressure inside the preparation chamber 1 is too high, the piston 702 will be pushed out under the relatively high pressure, and at this time, the fixed rod 703 will push the tension plate 704 outward to make the tension The tight plate 704 drives the spring 705 to stretch until the piston 702 is ejected from the inside of the through pipe 701...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com