An electrochromic concrete brick and its production process and manufacturing equipment

An electrochromic, concrete brick technology, applied in the field of concrete, can solve the problems of not considering the emergency guidance function, single function, etc., and achieve the effects of easy installation, reduced use, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] An underground space is used as an underground garage and underground warehouse. The owner puts forward the following requirements for the decoration of the underground space: 1. Requires color partitions; 2. Consider anti-static; It is convenient for personnel to escape in case of fire; 4. The material has good durability, high strength, and convenient construction.

[0075] According to the owner's needs, the present invention is trial-manufactured:

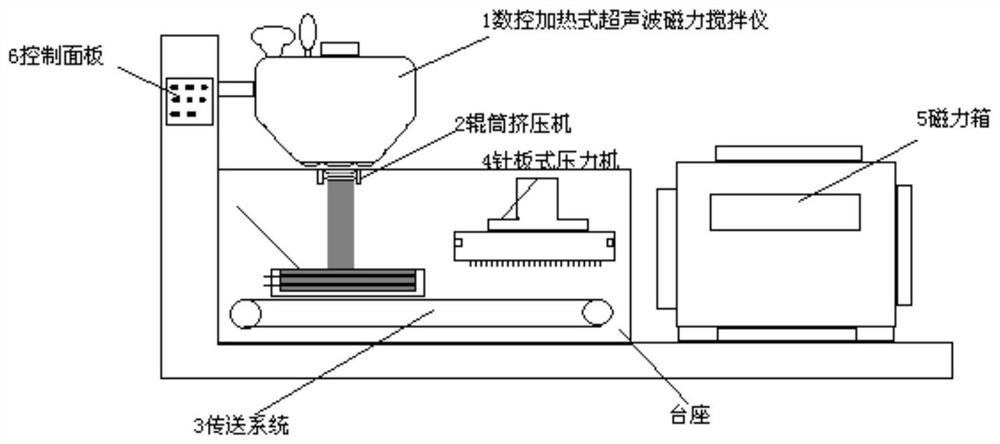

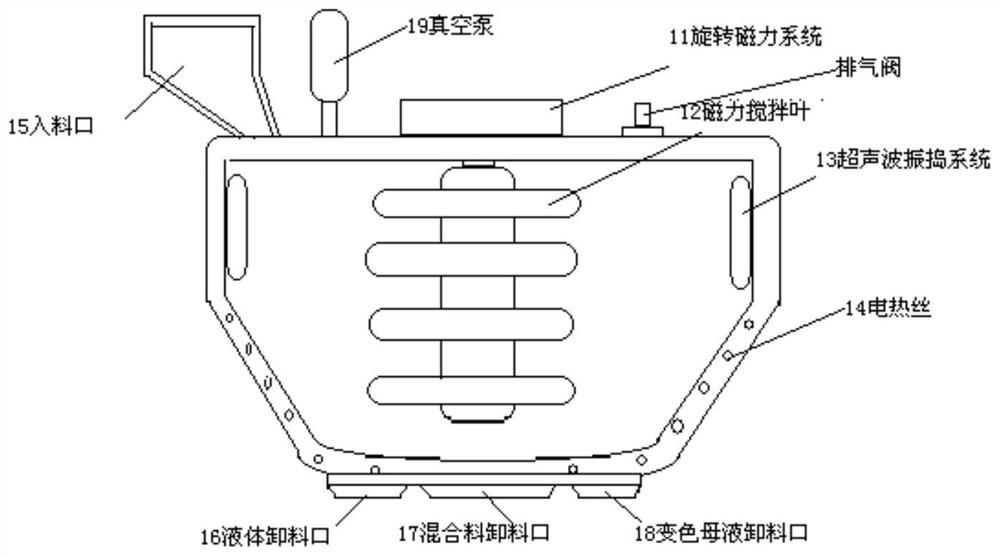

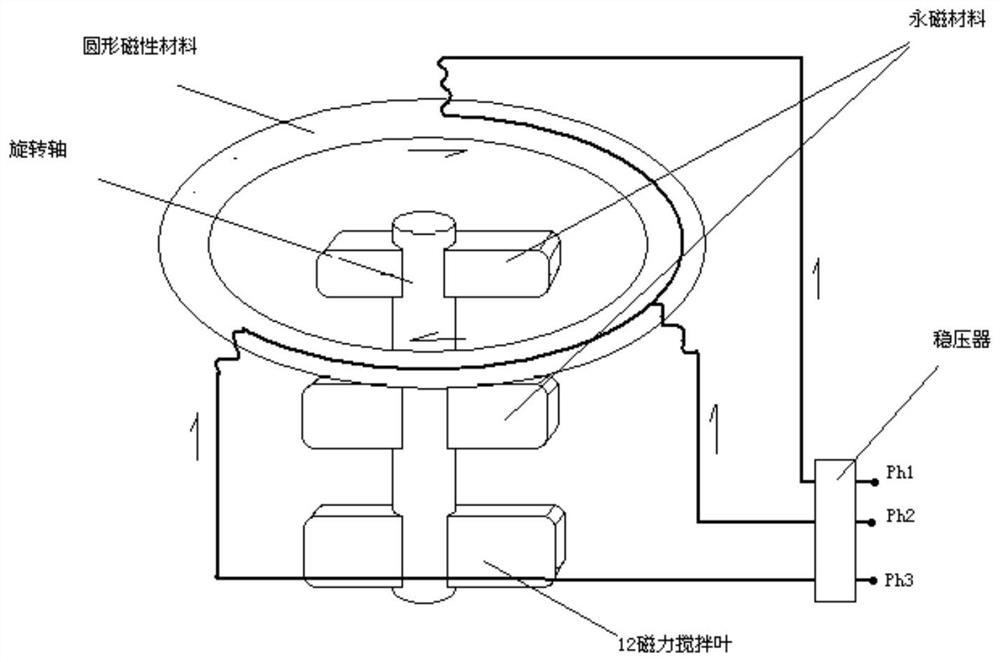

[0076] First, put the selected silane coupling agent 590 to prepare the coupling solution with a concentration of 30%, 12 components of nickel-plated carbon fiber and tetrazine derivatives of the reversible electrochromic material into the numerically controlled heating ultrasonic magnetic stirrer, and set the temperature to Set at 60°C, ultrasonic magnetic stirring for 2 hours first, then discharge excess liquid through the liquid discharge port, raise the temperature to 168°C to dry carbon fibers, and obtain reversible...

Embodiment 2

[0087] For the exterior wall of a pedestrian street, the owner put forward the following requirements for the decoration of the underground space: 1. It is required to have patterns that can appear at night and cooperate with the lighting of the pedestrian street to form an overall landscape; 2. Consider anti-static; 3. Meet the requirements of wear resistance, and Not easy to fall off; 4. The material has good durability, high strength, and convenient construction.

[0088] According to the owner's needs, the present invention is trial-manufactured:

[0089] First prepare the selected silane coupling agent 590 in proportion to a coupling solution with a concentration of 30%, 15 components of steel fiber and reversible electrochromic material tungsten trioxide (WO 3 ) into a digitally controlled heating ultrasonic magnetic stirrer, set the temperature at 80°C, first perform ultrasonic magnetic stirring for 2 hours, then discharge excess liquid through the liquid discharge port...

Embodiment 3

[0100] A customer made a TV background wall, and the owner put forward the following requirements for the decoration: 1. It is required to make an overall pattern; 2. Consider anti-static; 3. The lighting effect is good; 4. The material has good durability, high strength, and convenient construction, etc. .

[0101] According to the owner's needs, the present invention is trial-manufactured:

[0102] First, put the selected silane coupling agent 550 to prepare the coupling liquid with a concentration of 30%, 15 components of nickel-plated carbon fiber and tetrazine derivatives of reversible electrochromic materials into the numerically controlled heating ultrasonic magnetic stirrer, and set the temperature to Set at 60°C, ultrasonic magnetic stirring for 2 hours first, then discharge excess liquid through the liquid discharge port, raise the temperature to 168°C to dry carbon fibers, and obtain reversible electrochromic carbon fibers;

[0103] Then the epoxy resin is added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com