Spraying device for electromechanical equipment part machining

A technology of electromechanical equipment and spraying equipment, applied in spraying equipment, spray booths, etc., can solve problems such as uneven layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

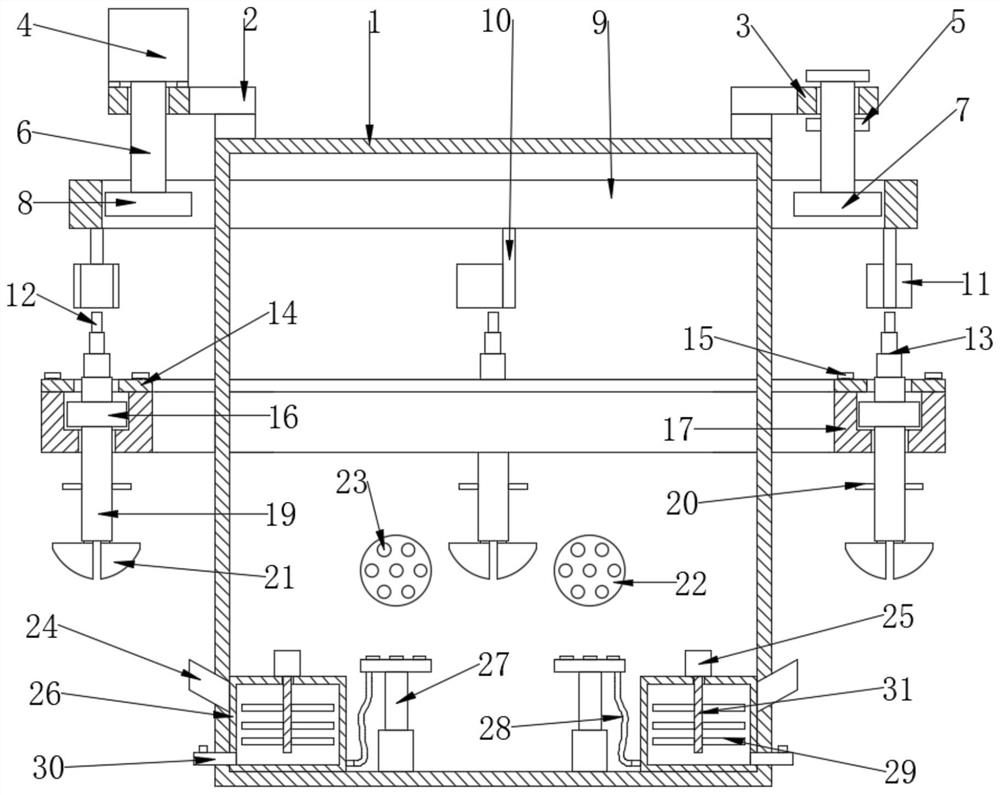

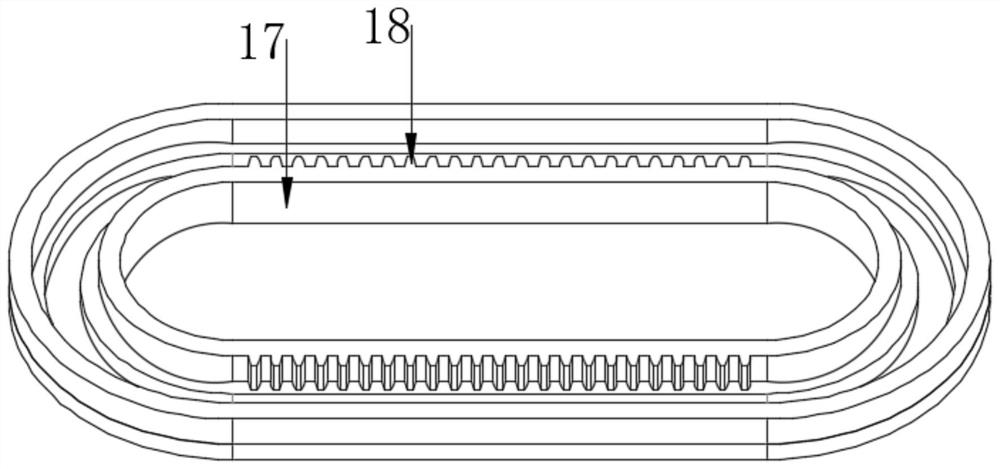

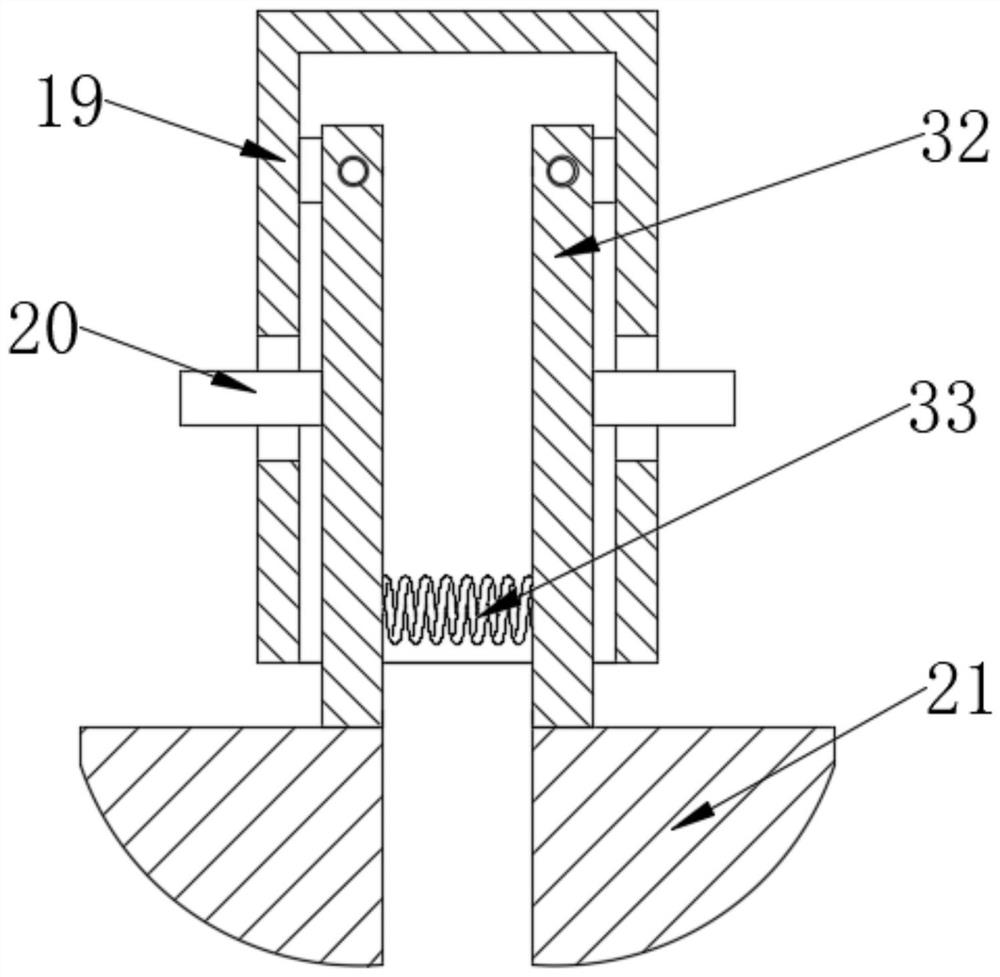

[0022] see Figure 1-4 , the present embodiment provides a kind of spraying device for the processing of mechanical and electrical equipment parts, including a processing box 1, and a spraying assembly is arranged in the processing box 1, and the spraying assembly includes respectively arranged in the processing box 1 Some spraying disks 22 on the side and up and down positions, some spraying heads 23 are arranged on the spraying disk 22, and a paint box 26 is also provided and useful On the conveying hose 28 connecting the two, a driving assembly, an intermediate assembly and a suspension assembly are also provided, and the two ends of the driving assembly and the intermediate assembly are respectively located outside the two sides of the processing box 1, and the driving assembly includes The driven chainring 7, the driving chainring 8 and the drive chain 9, the processing box 1 is fixedly connected with a limit collar 3 through a fixed bracket 2, wherein a limit collar 3 is...

Embodiment 2

[0031] On the basis of Embodiment 1, the suspension assembly includes a suspension part 19, a suspension suction cup 34 is provided at the lower end of the suspension part 19 and a pressure regulating pump 35 is arranged therein, and the surface of the workpiece is attached to the suspension suction cup 34 Inhale air through the pressure regulating pump 35 to form a negative pressure in the suspension suction cup 34 to achieve the purpose of suspending the workpiece. After the spraying is completed, release the air through the pressure regulating pump 35 to cancel the negative pressure and remove the workpiece.

Embodiment 3

[0033] On the basis of Embodiment 1, one end of the drive assembly and the intermediate assembly is located inside the processing box 1, and the other end is located outside the side of the processing box 1, so that the distance between the processing box 1 and the outside can be reduced. Notches to reduce outward scattering of spray paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com