Molybdenum-doped nickel cobaltate porous yolk-shell-structure material as well as preparation method and application thereof

A technology of shell structure and nickel cobaltate, which is applied in the field of molybdenum-doped nickel cobaltate porous egg yolk-shell structure materials and its preparation, can solve the problem that the electrochemical performance of nickel cobaltate needs to be improved, it is not easy to form defect sites, and the synthesis process is cumbersome Complicated problems, to achieve excellent electrochemical performance, reduce volume change, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0056] The third embodiment of the present invention provides an application of the molybdenum-doped nickel cobaltate porous yolk-shell structure material as a negative electrode material for a lithium-ion battery and / or in the preparation of a lithium-ion battery.

[0057] The present invention adopts the molybdenum-doped nickel cobaltate porous yolk-shell structure material as the negative electrode of lithium-ion batteries and / or to prepare lithium-ion batteries, and has more excellent electrochemical performance.

[0058] The fourth embodiment of the present invention provides a lithium-ion battery negative electrode, including a current collector, a binder, and an active component, and the active component is the above-mentioned molybdenum-doped nickel cobaltate porous egg yolk-shell structure material.

[0059] A fifth embodiment of the present invention provides a lithium-ion battery, including a lithium-ion positive electrode, an electrolyte, and the above-mentioned neg...

Embodiment 1

[0063] Place a 100mL beaker on a magnetic stirrer, add 30mL of N,N-dimethylformamide and 15mL of glycerol, and add 0.055g of Ni(NO 3 ) 3 ·6H 2 O, 0.110g Co(NO 3 ) 2 ·6H 2 O, 0.050gH 24 Mo 7 N 6 o 24 4H 2 O, after the solution was stirred for 30 minutes, 0.199 g of terephthalic acid was added, and the stirring was continued for 1.5 hours until it was completely dissolved, forming a pink solution. The obtained pink solution was transferred to a 100 mL reaction kettle, and solvothermally reacted at 180° C. for 6 h. After cooling, the purple solution was centrifuged and washed. The washed precipitate was dried at 70 °C for 12 h, and the dried precipitate was ground and calcined at 350 °C for 1 h to obtain Mo-doped NiCo 2 o 4 Material.

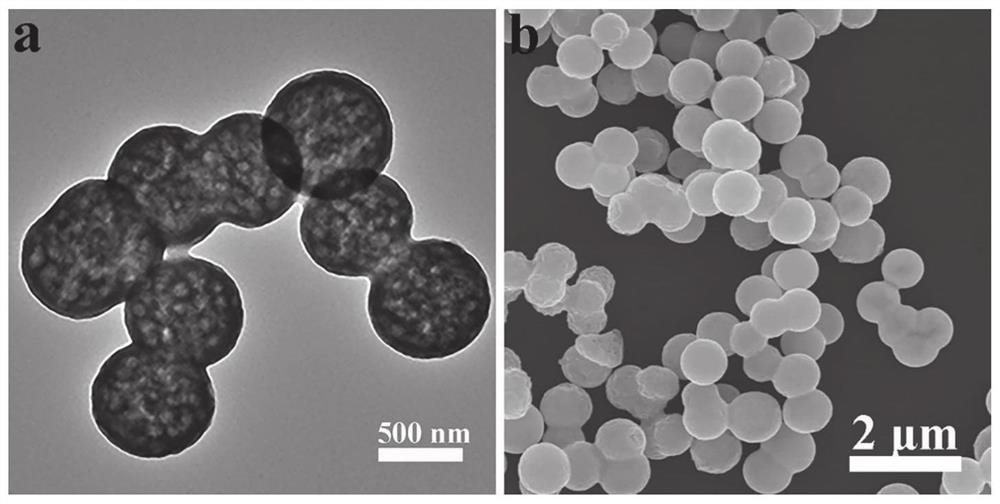

[0064] The Mo-doped NiCo obtained in this example 2 o 4 The shape of the material is as figure 1 shown, to show that the prepared Mo-doped NiCo 2 o 4 The material is a porous spherical structure.

Embodiment 2

[0066] Place a 100mL beaker on a magnetic stirrer, add 30mL of N,N-dimethylformamide and 15mL of glycerol, and add 0.055g of Ni(NO 3 ) 3 ·6H 2 O, 0.110g Co(NO 3 ) 2 ·6H 2 O, 0.050gH 24 Mo 7 N 6 o 24 4H 2 O, after the solution was stirred for 30 minutes, 0.199 g of terephthalic acid was added, and the stirring was continued for 1.5 hours until it was completely dissolved, forming a pink solution. The obtained pink solution was transferred to a 100 mL reaction kettle, and solvothermally reacted at 180° C. for 6 h. After cooling, the purple solution was centrifuged and washed. The washed precipitate was dried at 70 °C for 12 h, and the dried precipitate was ground and calcined at 500 °C for 1 h to obtain Mo-doped NiCo 2 o 4 Material.

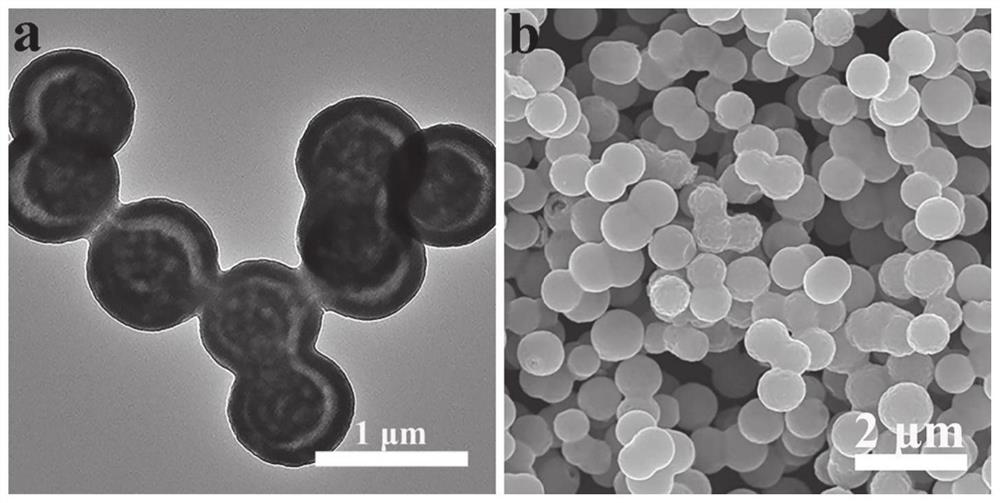

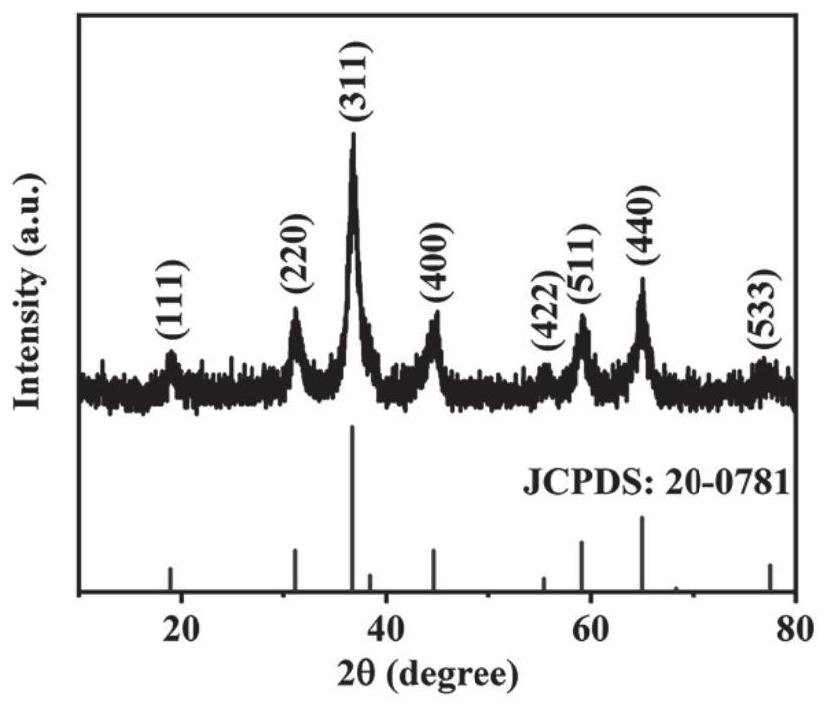

[0067] The Mo-doped NiCo obtained in this example 2 o 4 The shape of the material is as Figure 2~3 , indicating that the prepared Mo-doped NiCo 2 o 4 The material is a porous egg yolk-shell structure, the diameter of the yolk-she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com