Automatic processing system for corrugated board preparation

A corrugated cardboard and processing system technology, which is applied in metal processing, mechanical processing/deformation, chemical instruments and methods, etc., can solve the problems of reduced work efficiency, inability to glue and pave corrugated cardboard, and inability to unload corrugated cardboard, etc. To achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

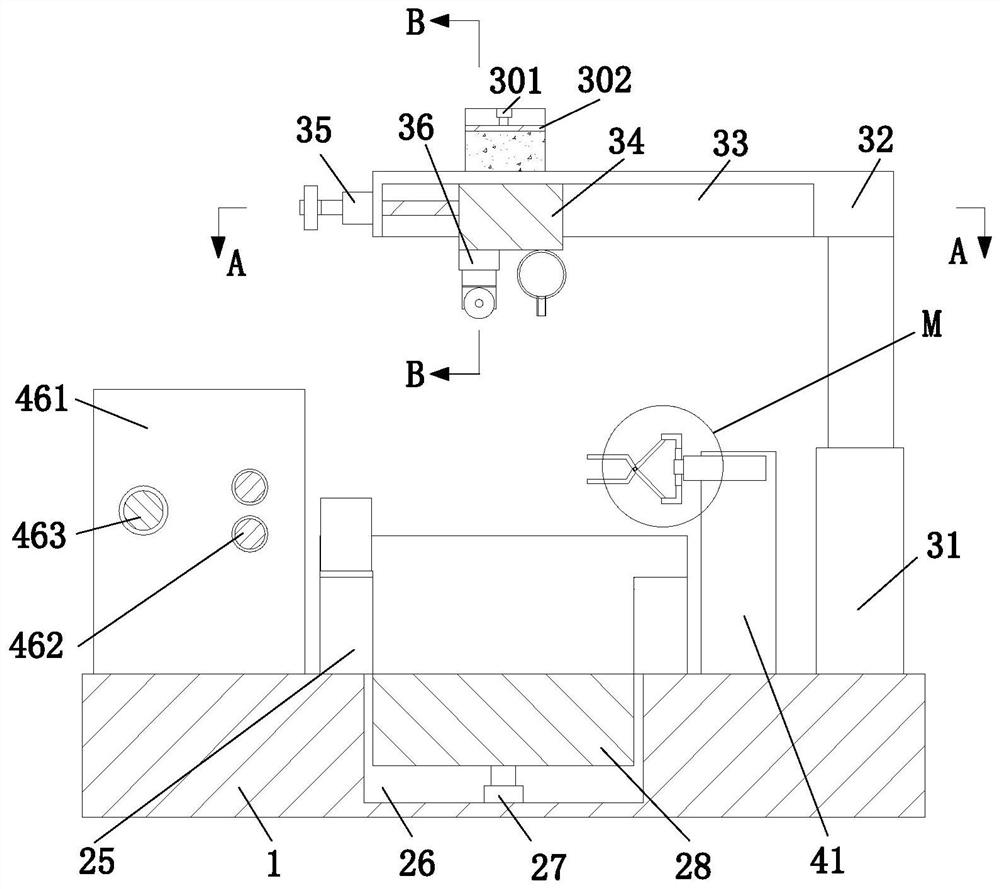

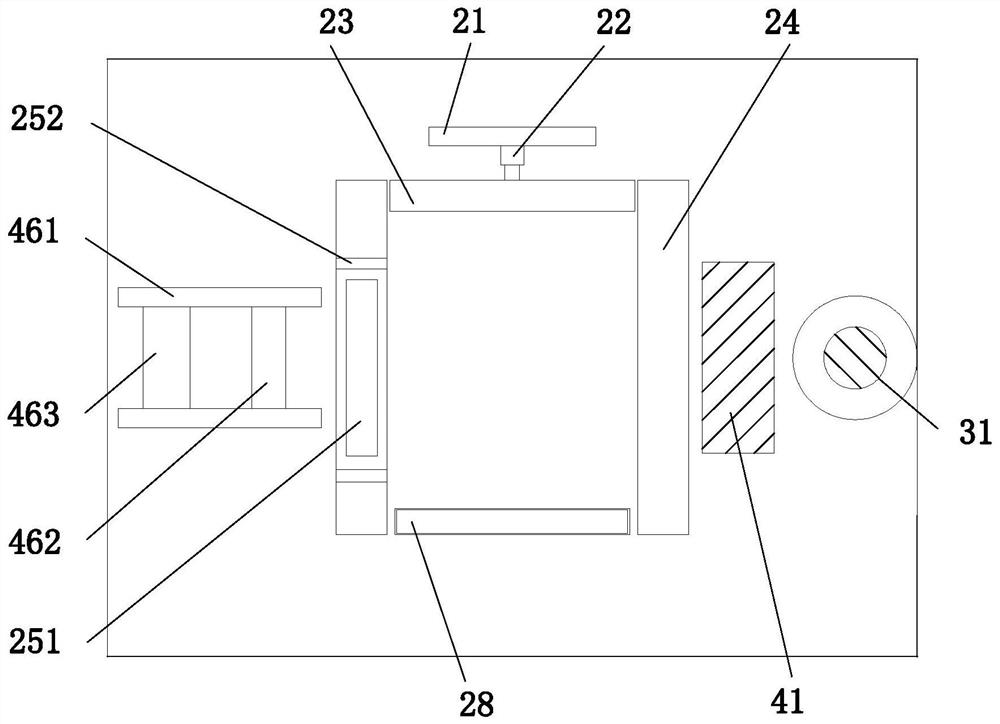

[0030] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

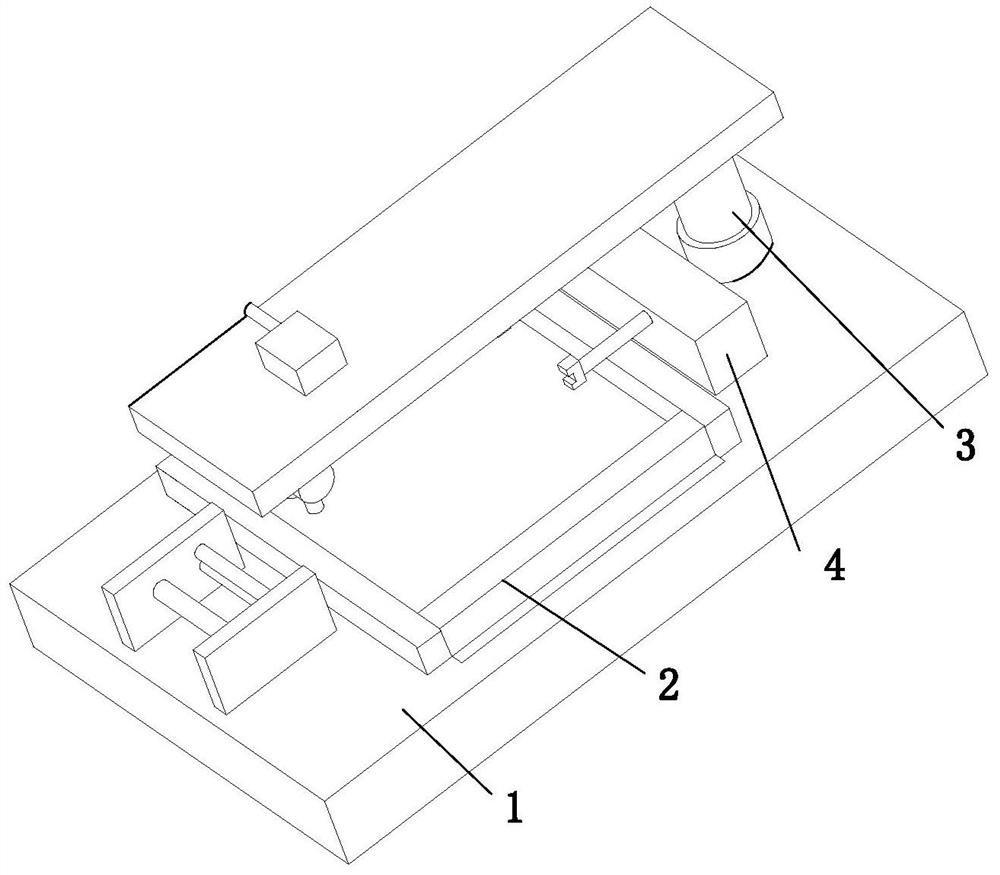

[0031] An automatic processing system for the preparation of corrugated cardboard, comprising a workbench 1, a fixing device 2, a gluing device 3 and a moving device 4, the fixing device 2 is arranged at the center of the top of the workbench 1, and the top of the workbench 1 and A gluing device 3 is provided on the right side of the fixing device 2, and a moving device 4 is provided on the top of the workbench 1 and on the left side of the gluing device 3;

[0032] The fixing device 2 includes a vertical plate 21, a No. 1 electric cylinder 22, a push plate 23, a limit plate 24, a cutting frame 25, a No. 1 rectangular groove 26, a No. 1 telescopic rod 27 and a rectangular long block 28. A vertical plate 21 is fixedly installed at the top rear end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com