Positioning tool mold for machining and using method thereof

A technology of mechanical processing and positioning tooling, applied in the field of mechanical processing, can solve the problems of inconvenient mold fixing, inconvenient parts removal, and troublesome parts in the mold, so as to save time and effort in the installation and fixing process, and the installation and fixing of the mold is simple and convenient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

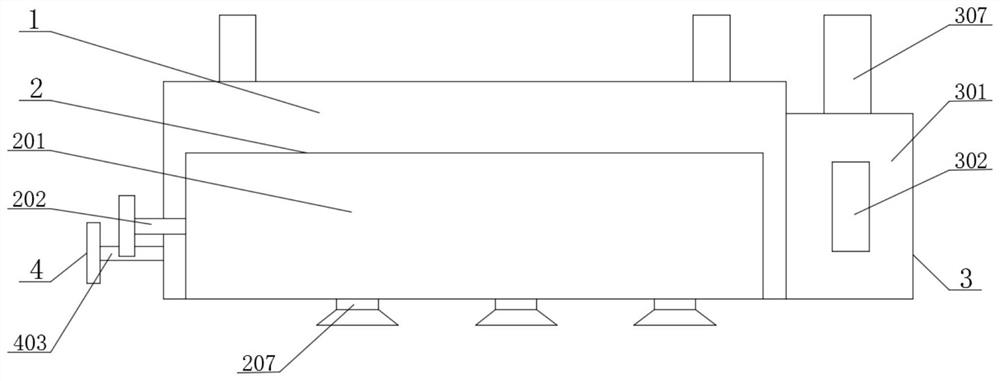

[0032]SeeFigure 1-6The present invention provides a technical solution:

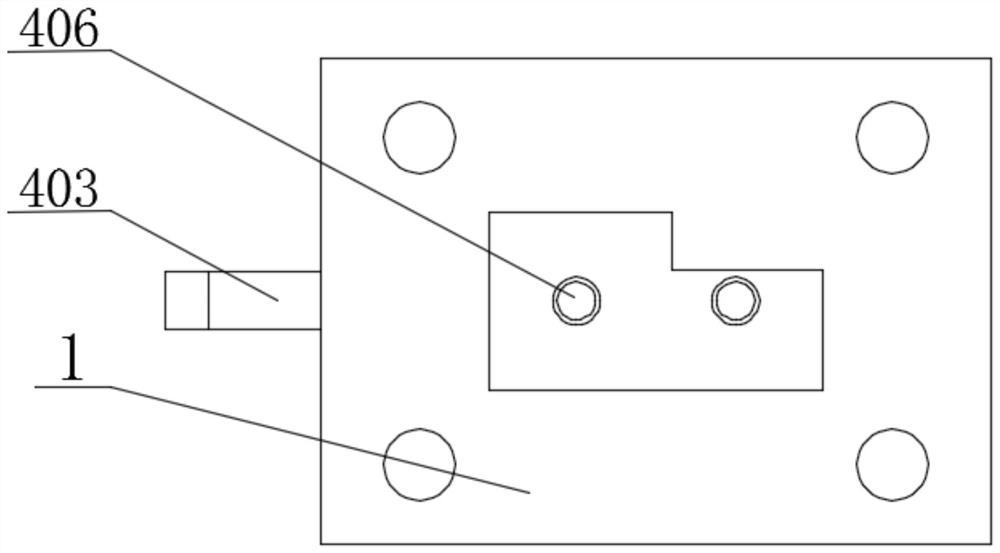

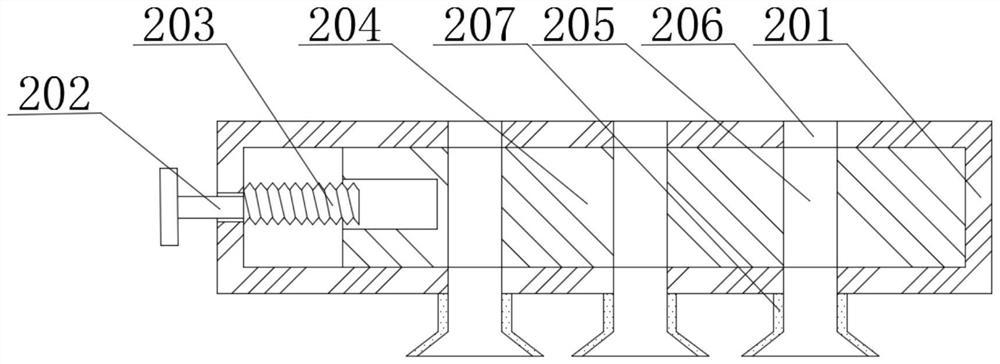

[0033]A mechanical machining positioning tool mold, including the mold body 1, the fixing device 2, the positioning device 3, and the top outfit device 4, the fixing device 2 includes a mounting plate 201, the mounting plate 201 is fixed to the mold body 1, the mounting plate 201 left end face The first handle 202 is rotatably connected to the mounting plate 201, and the first handle 202 is fixed to the first threaded shaft 203, and the first threaded shaft 203 is helically connected to the slide 204, the slide 204 and the mounting plate 201 slide, The inside of the slide 204 is opened with a first hole hole 205, and the top surface of the mounting plate 201 is opened with a second hole hole 206, and the bottom end surface of the mounting plate 201 is connected to the suction cup 207, which is convenient to secure the mold to the workbench.

[0034]The positioning device 3 includes a first positioning plate 301, and...

Embodiment 2

[0037]Embodiment 2 is not described in the same part as in Example 1, seefigure 2 ,image 3 ,Figure 4 ,Figure 5 ,Figure 7 ,Figure 8 withFigure 9 The present invention provides a technical solution:

[0038]The positioning device 3 includes a second positioning plate 308, and the second positioning plate 308 is fixedly coupled to the mold main body 1, and the second positioning plate 308 is fixedly connected to the controller 309, and the inner side fixed connection between the second positioning plate 308 is fixedly connected to multi-stage electric telescopic. The rod 310, the plurality of electric telescoping rod 310 is fixed to the connecting plate 311, and the connecting plate 311 is slidably connected to the second positioning plate 308, and the connecting plate 311 is slidably connected, and the connecting plate 311 is rotated and the rotating rod 312 is connected. The other end of the rotating rod 312 is rotated to be connected to the second pinch plate 313, and the second pinch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com