Method for suppressing slime in reverse osmosis membrane apparatus

A technology of reverse osmosis membrane and slime, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as increased operating costs and obstacles to continuous operation of reverse osmosis membrane devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0098] As a production example of sodium chlorosulfamate, for example, the method described in Example 1 of Japanese Patent No. 5720964 is mentioned.

[0099] Add component (B-1), that is, chloramine composed of ammonium salt and chlorine, so that the maintenance concentration in the system is preferably 0.5 to 7.0 mg / L (based on Cl concentration) in terms of total chlorine concentration. 2 ), more preferably 0.5-5.0 mg / L (as Cl 2 ), more preferably 1.0 to 3.0 mg / L (as Cl 2 count).

[0100] By maintaining the concentration of the above-mentioned component (B-1) in the system within the above-mentioned range, it is easy to obtain the effect of suppressing the generation of slime (biofilm) in a short time, and even if the slime (biofilm) is generated and attached to the reverse osmosis The film surface can also be used to remove slime (biofilm) by combining with DBNPA, which is a slime inhibitor X.

[0101] Add component (B-2), i.e. chlorosulfamic acid or chlorosulfamate, so ...

Embodiment 1

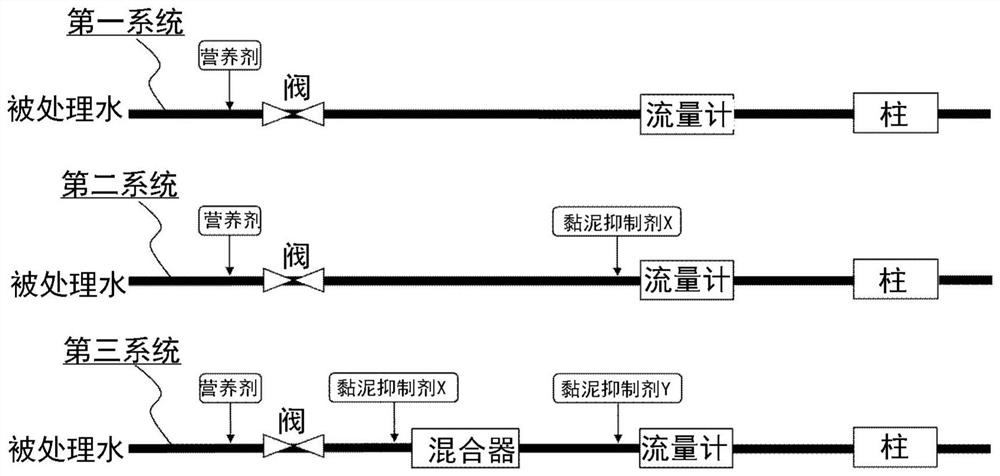

[0186] use figure 2 In the third system of the simulated device shown, open the valve and pass the treated water (raw water) prepared above for 7 consecutive days under the condition of 1.7 L / min. In addition, the nutrient prepared above was added to the treated water for 7 consecutive days under the condition of 1 mL / min, and the DBNPA reagent prepared above was added as the slime inhibitor X at a frequency of 30 minutes once a day, so that the system of DBNPA Keep the concentration at 10mg / L (in terms of DBNPA), and add the above-mentioned component (B-2) sodium monochlorosulfamate reagent as the slime inhibitor Y, so that the maintenance concentration in the system is 2.4mg in terms of total chlorine concentration / L (as Cl 2 count).

Embodiment 2

[0188] The kind of slime inhibitor Y among the embodiment 1 is changed into component (A), namely the mixture reagent of Cl-MIT and MIT, and the maintenance concentration in the system that changes into Cl-MIT is 1.5mg / L (with Cl-MIT In addition to this, the water passing process was carried out in the same manner as in Example 1, which was used as the slime suppression test in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com