anti-vibration hammer

An anti-vibration hammer and pulley technology, applied in mechanical vibration damping devices and other directions, can solve the problems of failure to meet the anti-vibration requirements of transmission lines, threats to life safety, and heavy workload, so as to reduce the threat of personal accidents, avoid personal threats and economic losses. , The effect of good energy absorption and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

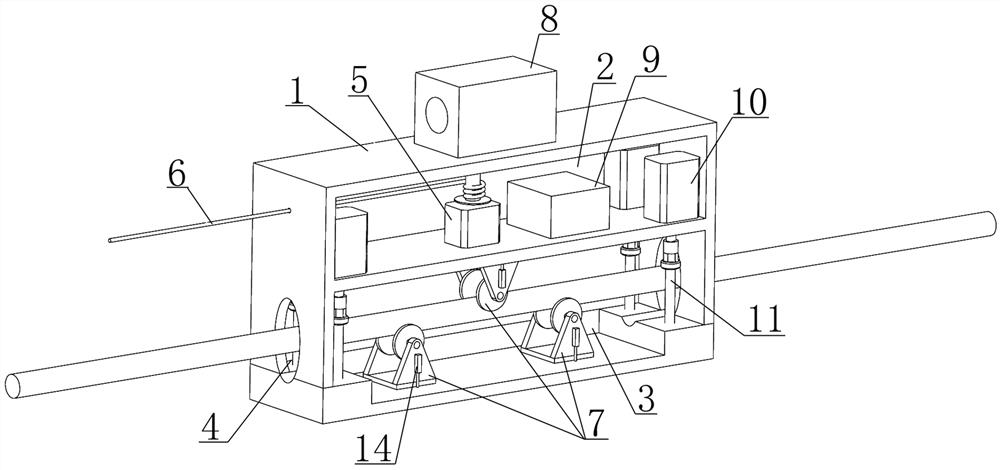

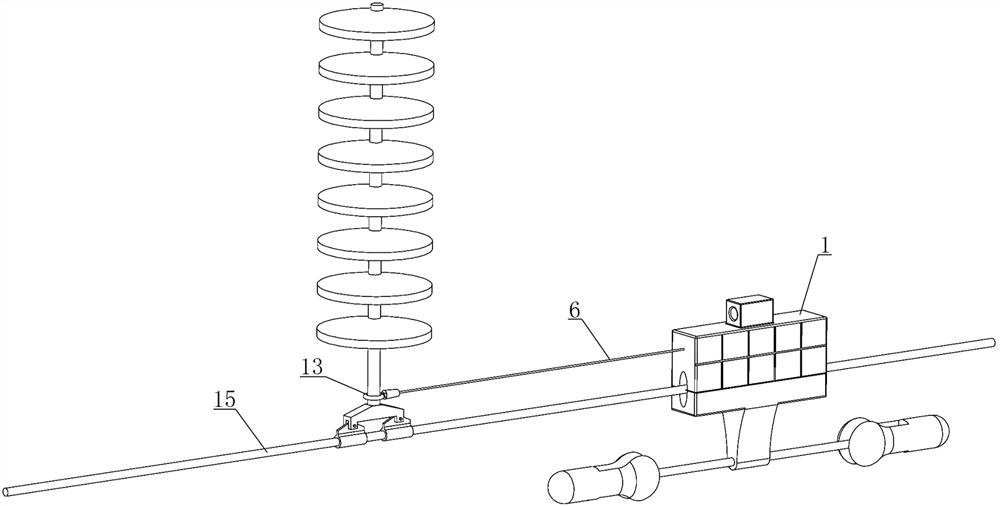

[0063] like figure 1 and figure 2 As shown, a block anti-vibration hammer includes a block 1, and the anti-vibration hammer is suspended at the bottom of the block 1. The interior of the block 1 includes a first chamber 2 and a second chamber 3. On both sides of the second chamber 3 The wall is penetrated with a second perforation 4 for overhead power transmission wires to pass through, a first perforation is provided on the side wall of the first chamber 2, a pull wire mechanism 5 is fixed in the first chamber 2, and one end of the traction rope 6 It is connected with the pull wire mechanism 5, and the other end is from the inside of the first chamber 2 to the outside and passes through the first perforation; a wire pulley 7 is provided in the second chamber 3, and the wire pulley 7 is used to drive the pulley 1 on the transmission line Move the location.

[0064] In order to make the trolley 1 lock well with the overhead power transmission wire when it moves to the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com