Fire grate block structure of garbage incinerator and fixed connection mode of fire grate block structure

A waste incinerator and block arranging technology, which is applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of grate block rotation and tilting, and achieve the goals of improving permeability, preventing tilting, and improving combustion conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

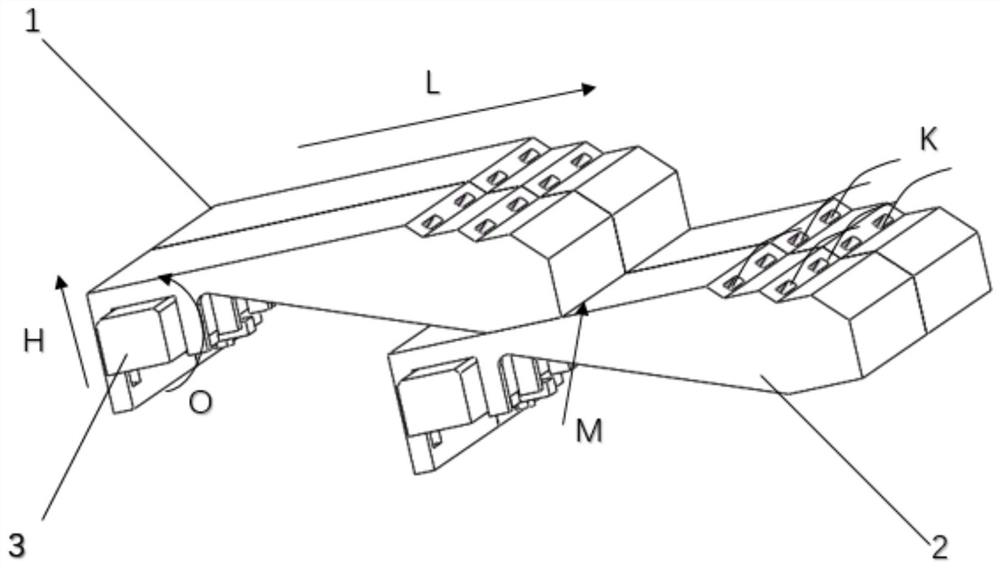

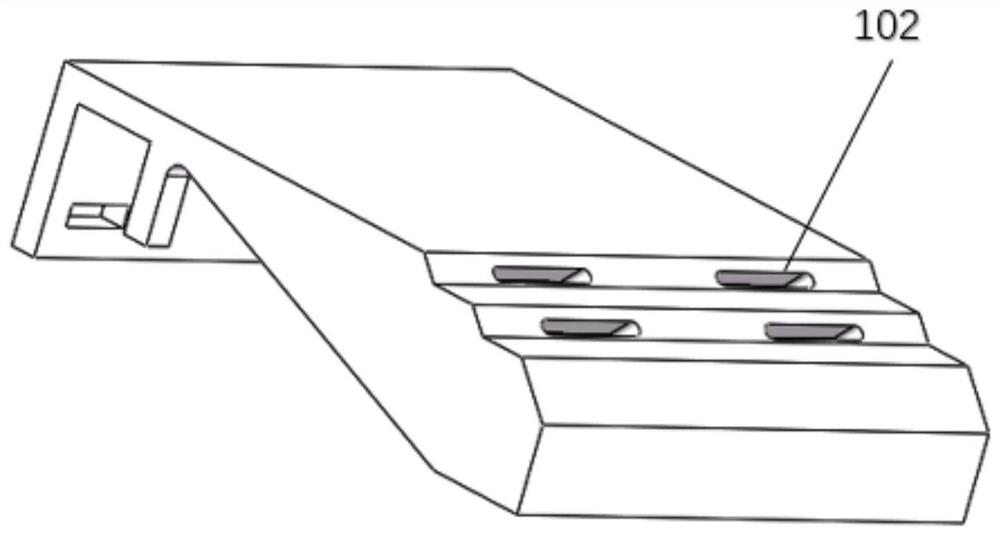

[0028] exist figure 1 Among them, the movable grate block (1) and the fixed grate block (2) are overlapped and arranged along the waste material conveying direction (L), and the movable grate block (1) and the fixed grate block (2) pass through the rectangular slot ( 104) are fastened on the grate beam (3), and arranged side by side to form a row of grate.

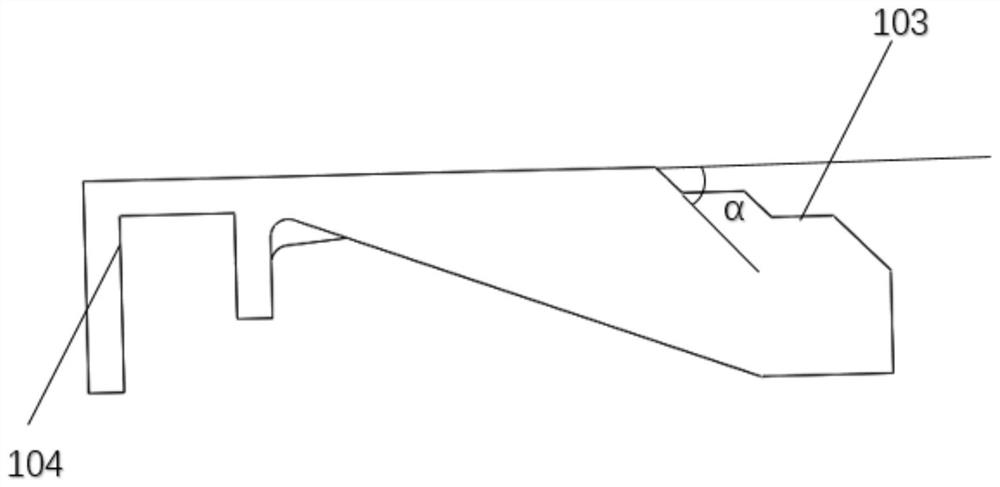

[0029] Further, when the structural rectangular clamping groove (104) of the rear half of the grate block is engaged with the similarly rectangular grate beam (3), it can ensure that the upper top surface and both sides of the grate block are respectively connected with the three sides of the grate beam (3). contact, to prevent the grate block from rotating along the axial direction of the grate beam (3), as shown in Figure O, thereby avoiding the occurrence of hard foreign matter stuck at the contact point (M) be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com