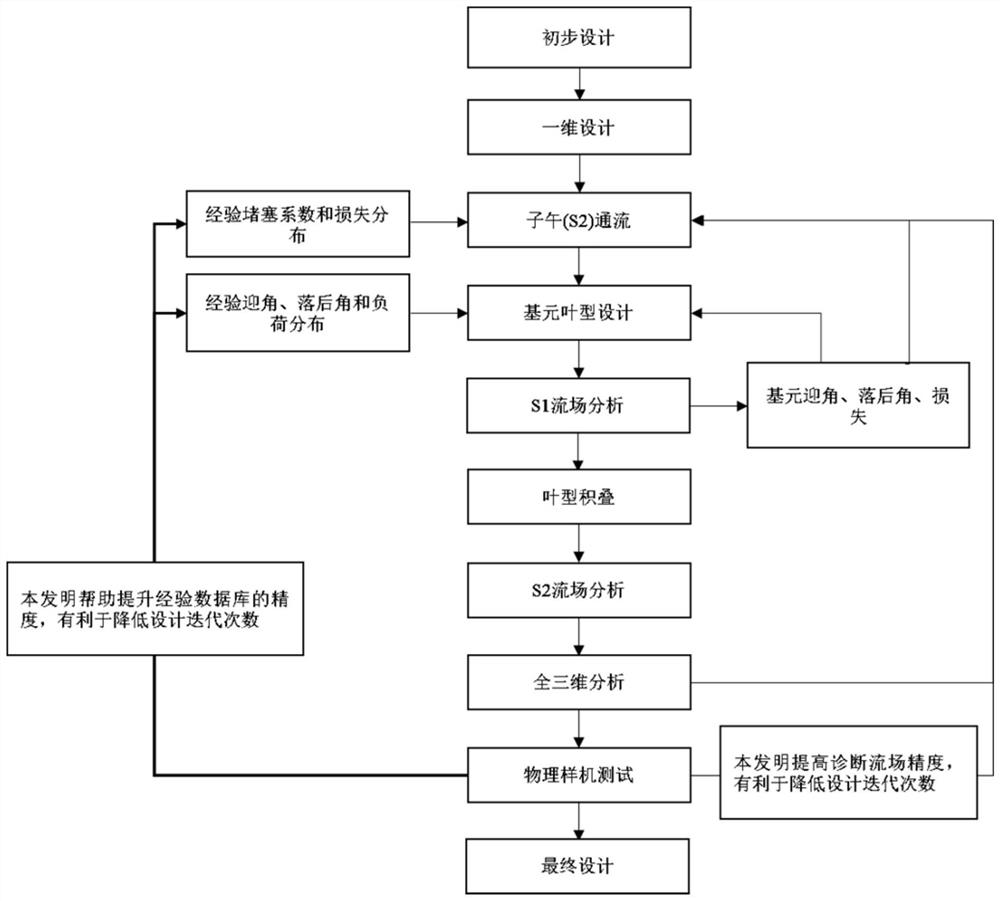

S2 flow field diagnosis method based on inter-stage measurement parameters of axial flow compressor

An axial-flow compressor, a technology for measuring parameters, applied in gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of multi-stage compressor matching damage, accumulated errors, and deviation of calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0212] Example description:

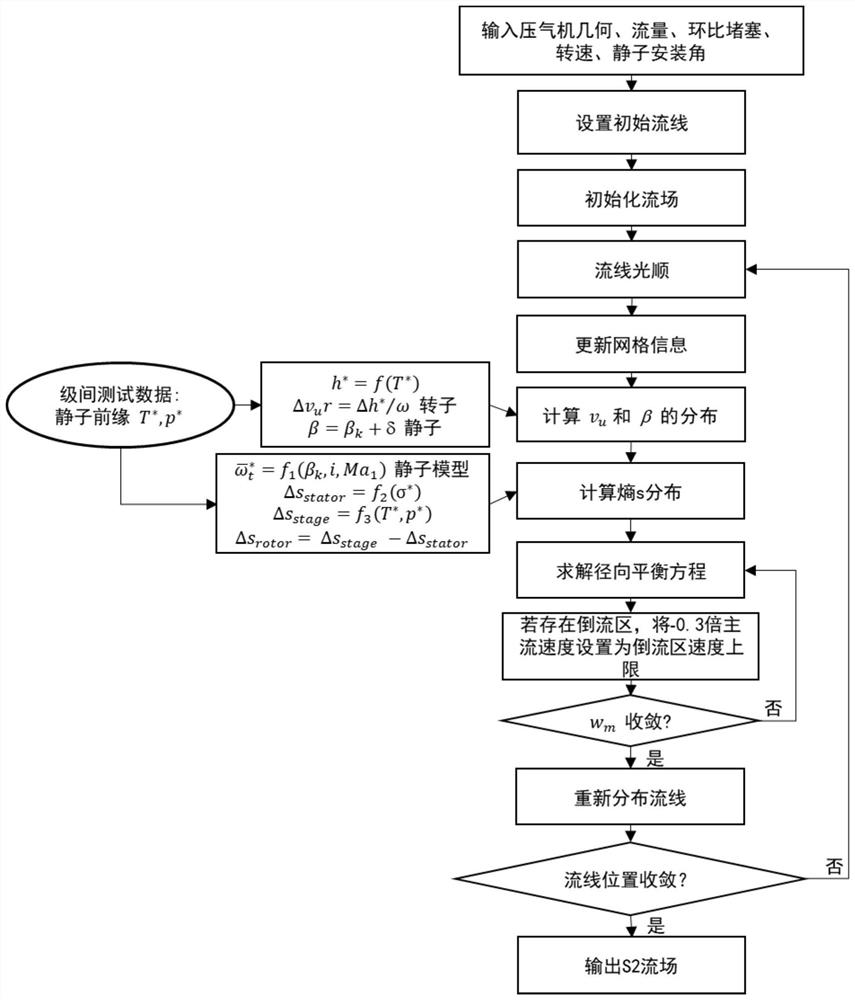

[0213] Based on the present invention, a S2 flow field diagnosis method based on the interstage measurement parameters of the axial flow compressor is proposed, and the application of this method in the S2 flow field diagnosis process of the multistage compressor is initially explored, and the feasibility of the present invention is verified by comparative analysis sex.

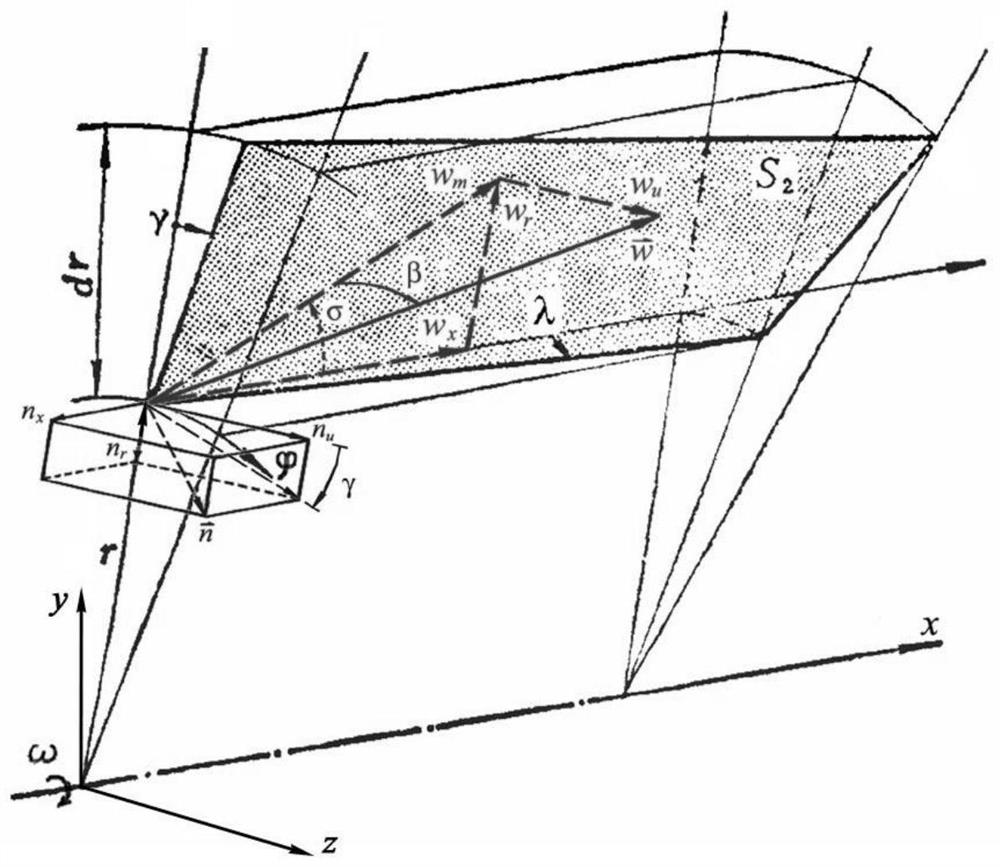

[0214] In view of the dimensionality reduction characteristics and model selection brought about by the governing equations, the key technologies and difficulties can be summarized as follows:

[0215] 1) In the compressor prototype test, it is very likely to work at a non-design point

[0216] Under such working conditions, there may be obvious flow separation, and the angle of attack seriously deviates from the design working point. Its flow field may deviate greatly from the design conditions, and in severe cases, meridian backflow may occur. To solve this difficulty, in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com