Scaffold

A technology of scaffolding and support frame, applied in the field of scaffolding, can solve the problems of shaking safety, hidden dangers, workers prone to rollover when climbing, and achieve the effect of preventing rollover and increasing the degree of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

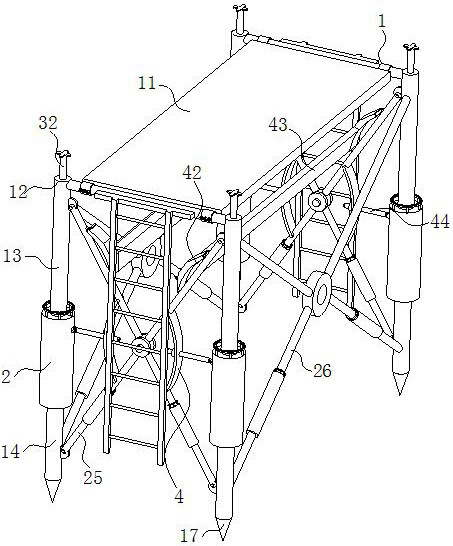

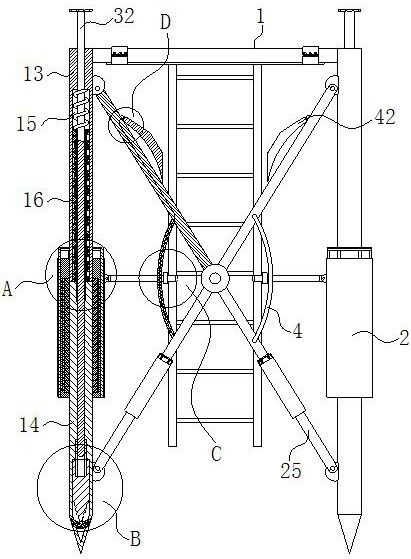

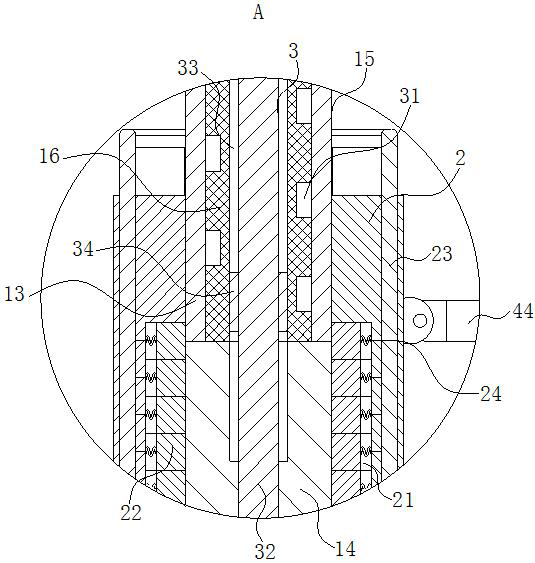

[0029] Example 1, such as Figure 1-Figure 6 Shown, a kind of scaffolding described in the present invention comprises support frame 1; The quantity of described support frame 1 is two and corresponds to each other; Both described support frames 1 are fixedly connected with struts; Two described support frames 1. On the opposite side of the supporting frame 1, a frame plate 11 is fixedly connected by bolts; the two supporting frames 1 include two supporting columns 12; each of the supporting columns 12 includes an upper column 13 and a lower column 14; the inner wall of each upper column 13 is provided with a first sliding groove 15, and the first sliding groove 15 communicates with the lower surface of the upper column 13; the upper surface of each lower column 14 is fixedly connected with a first sliding groove rod 16, and the first sliding rod 16 is slidably connected with the first chute 15; each of the first sliding rods 16 is connected with the first chute 15 by a spring...

Embodiment 2

[0032] Example 2, such as Figure 1-Figure 6 As shown, a first helical groove 31 is provided in the inner wall of each of the first sliding rods 16, and the first helical groove 31 cooperates with the block 22; each of the inner walls of the first sliding rod 16 is provided with a The third chute 3, and the second slide bar 32 is slidably connected to the inner wall of the third chute 3, and the second slide bar 32 partly stretches out from the upper surface of the pillar 12; each of the third chute 3 inner walls There are evenly arranged first slots 33, and the first slots 33 partially extend into the inner wall of the lower column 14; the outer surface of each of the second sliding rods 32 is fixed with evenly arranged first side plates 34, and The first side plate 34 cooperates with the first slot 33;

[0033] When working, because the first helical groove 31 and the block 22 cooperate with each other, after the adjustment of the support column 12 is completed, part of the...

Embodiment 3

[0034] Example 3, such as Figure 1-Figure 6 As shown, each of the second sliding rods 32 extends into the inner wall of the lower column 14 and is slidably connected with the lower column 14; a tapered groove is provided in the inner wall of the tapered column 17 below each of the second sliding rods 32 35; each of the tapered grooves 35 is slidably connected with a tapered block 36, and the outer surface of the tapered block 36 is provided with a second thread groove 37; each of the tapered blocks 36 inner walls are provided with a cross Groove 38; the top of each cross groove 38 is fixedly connected with the second side plate 39 uniformly arranged on the outer surface of the second slide bar 32, and the second side plate 39 cooperates with the cross groove 38; each of the cones Evenly arranged insertion rods 391 are slidably connected to the inner wall of the cone column 17 below the shape block 36, and the insertion rods 391 are all matched with the second threaded groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com