Building drilling and filling auxiliary sleeve

A filling and construction technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve problems such as the failure of expansion screws to cooperate with the connection, damage to the support between expansion screws and walls, poor connection stability between expansion screws and walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

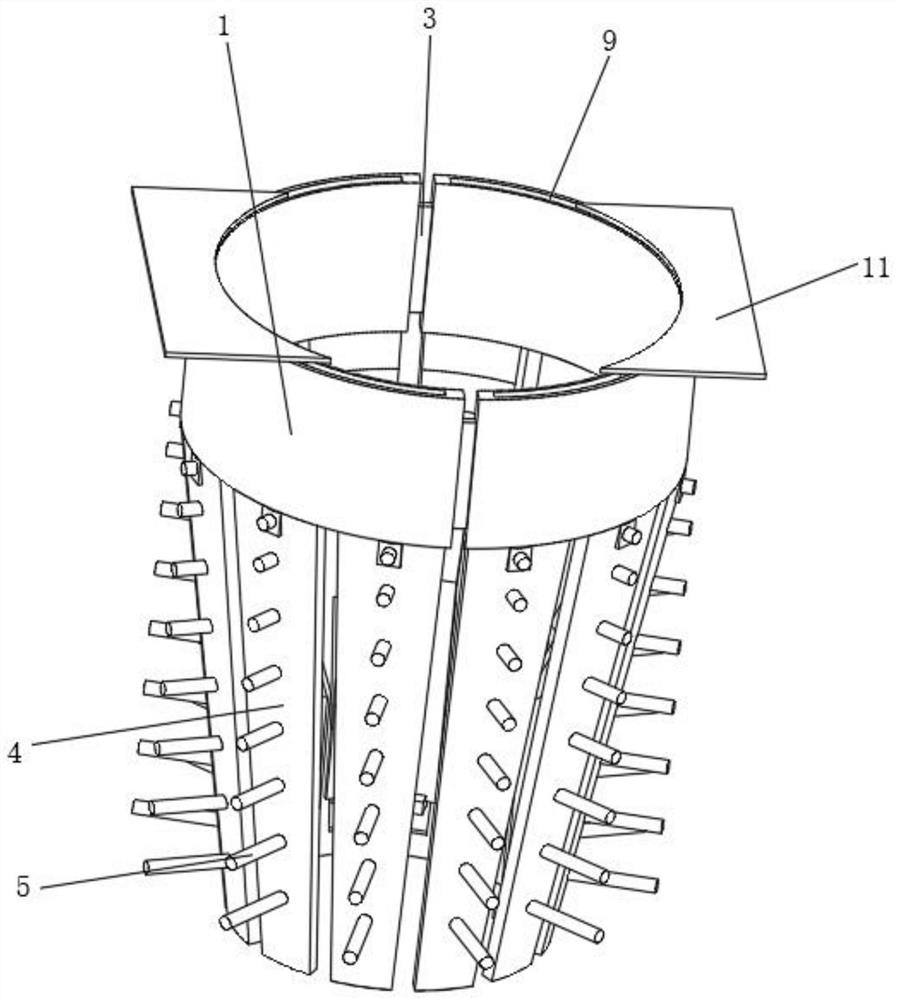

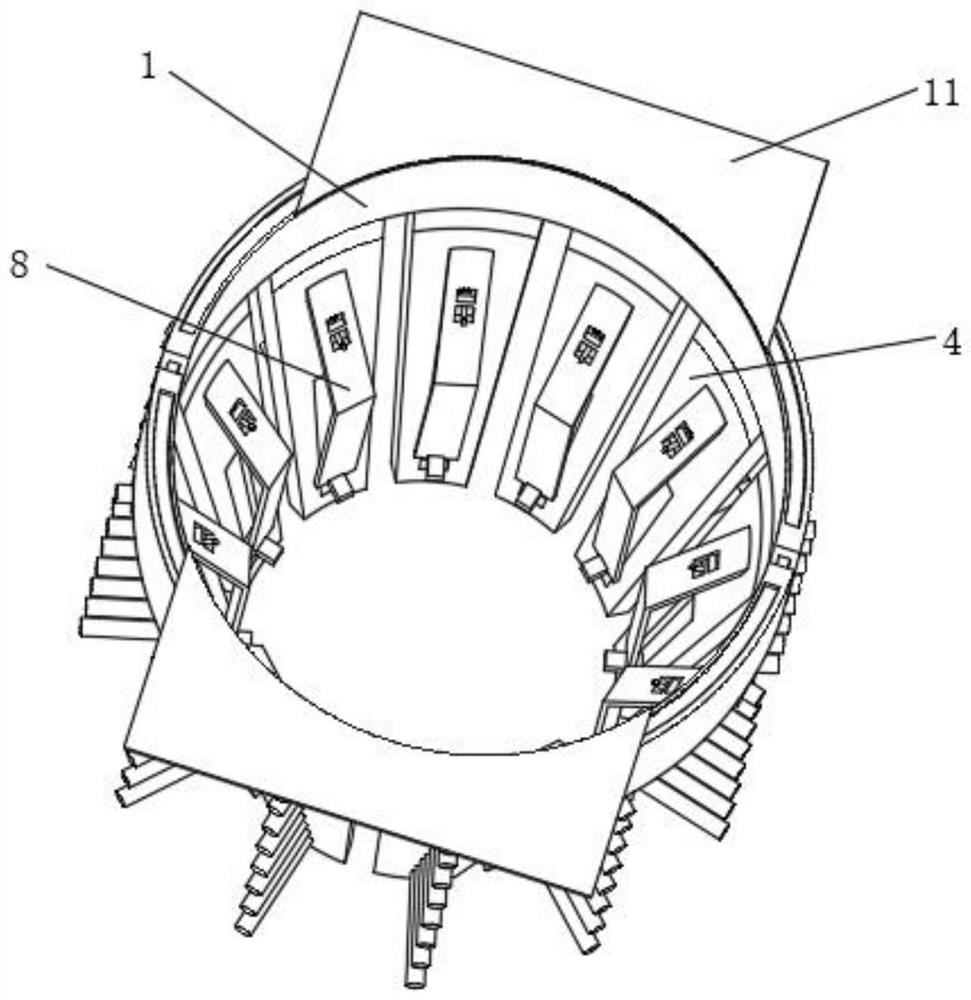

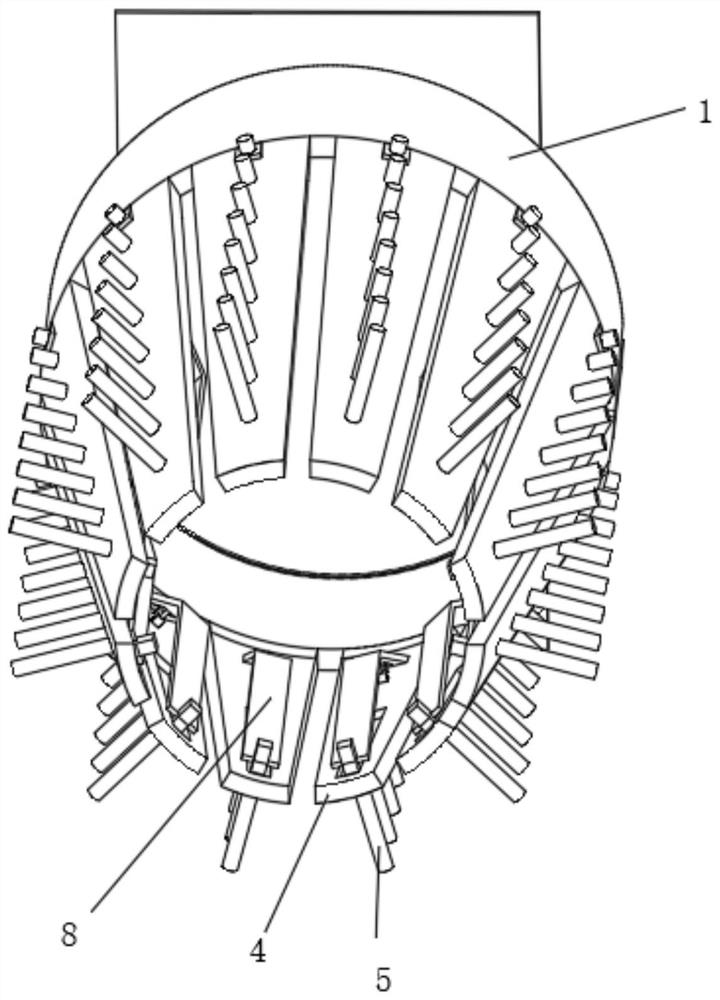

[0037] Such as Figure 1-5As shown, the present invention provides a technical solution: a construction drilling and filling auxiliary sleeve, including a hole wall limiting splint 1, and the middle position of the two hole wall limiting splints 1 is provided with an adjustment through groove 2, and the adjustment through groove 2 The interiors of the holes are all penetrated and slidably connected with an adjustment extension rod 3, and the two hole wall limiting splints 1 are combined to form a ring shape, and the bottom surface of the hole wall limiting splint 1 is evenly spaced and fixedly connected with inner fitting clips 4, and the inner fitting clips 4 are connected. The clips 4 are arranged inclined toward the inner side, and the inner fitting clips 4 are combined to form a circular truncated shape. The middle position near the bottom of the internal test is fixedly connected with the travel track 6, the inner sliding connection of the travel track 6 is connected with...

Embodiment 2

[0039] Such as Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a construction drilling and filling auxiliary sleeve, the inner fitting clip 4 is in the middle position of the internal measurement and is located above the travel track 6 and is connected with a rotating Block 12, one end of the outer side of the rotating block 12 is fixedly connected with a spring pressing rod 13, and the top of the rotating block 12 is fixedly connected with a supporting push rod 14, and the spring pressing rod 13 and the supporting pushing rod 14 are vertically arranged. Reduce the initial entry resistance of the expansion screw and reduce the difficulty of installation of the expansion screw.

[0040] One end of the spring pressing rod 13 away from the rotating block 12 is rotatably connected with a guide roller 15 .

[0041] A stabilizing needle plate 16 is fixedly connected to the end of the supporting push rod 14 away from the rotat...

Embodiment 3

[0043] Such as Figure 6-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a kind of building drilling and filling auxiliary sleeve, the feeding stabilization mechanism 8 includes a deformation fitting plate 81, the bottom of the deformation fitting plate 81 and The limiting slider mechanism 7 is fixedly connected, and the top of the deformable fitting plate 81 is fixedly connected with a support pressing plate 82 , and the inner side of the top of the supporting pressing plate 82 is in contact with the surface of the inner fitting clip 4 . There is an elastic force between the deformation fitting plate 81 and the support plate 82, which can increase the frictional resistance between the expansion screw and the auxiliary sleeve, and ensure the stability of the expansion screw installation.

[0044] The middle positions of the supporting platen 82 are respectively provided with restricting opening grooves 83 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com