Rotary staggered discharging structure and tableware taking device thereof

A rotary tableware technology, applied in the field of mechanical equipment, can solve the problems of increasing the weight of the tableware taker, many procedures, unreliable whereabouts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

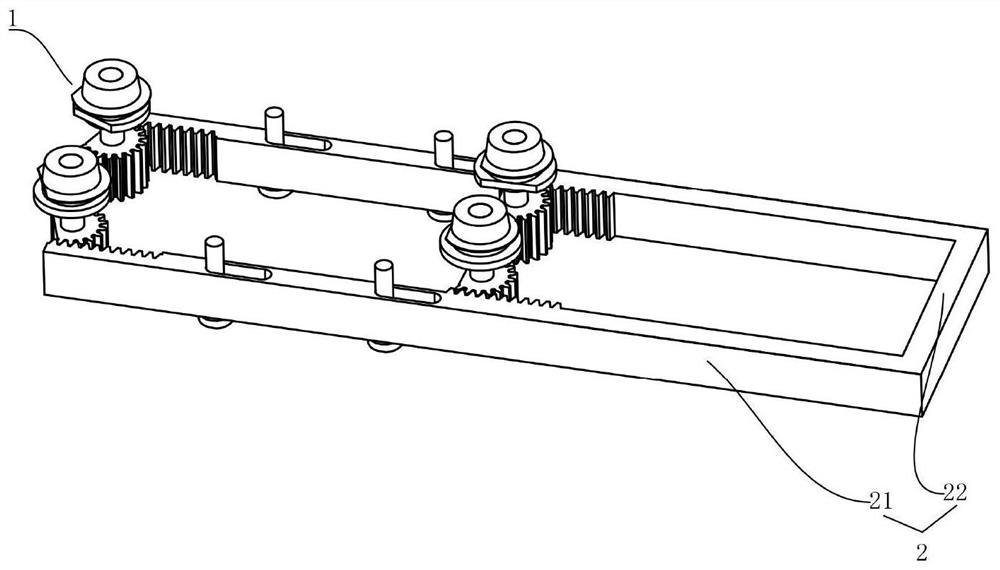

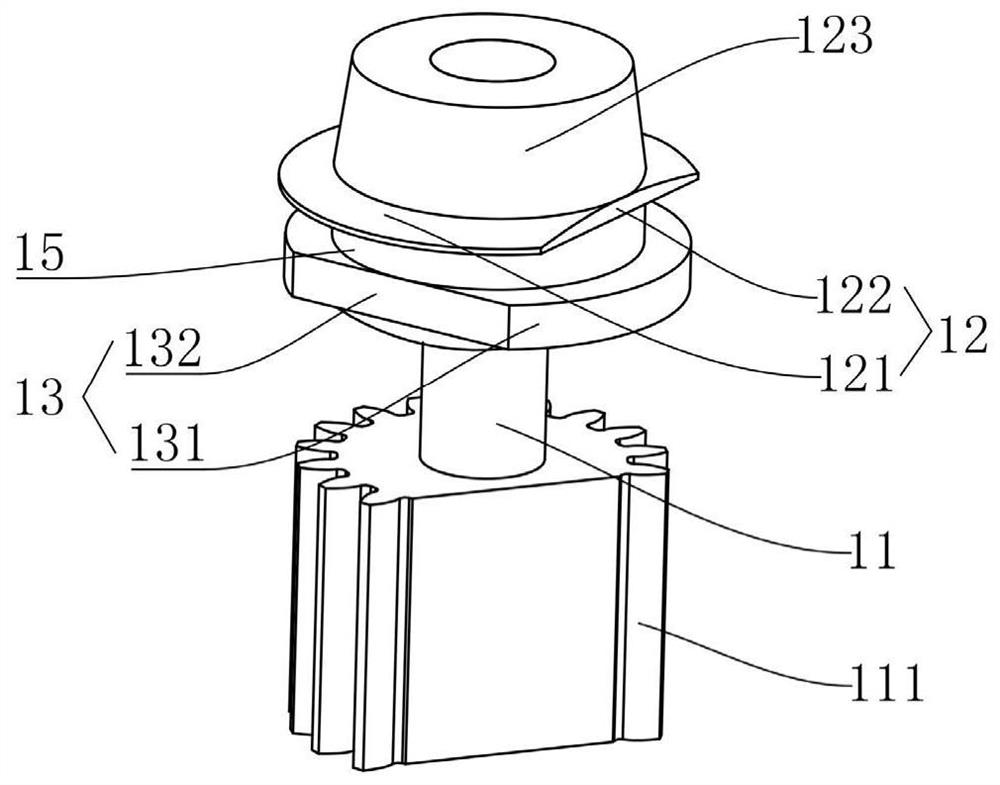

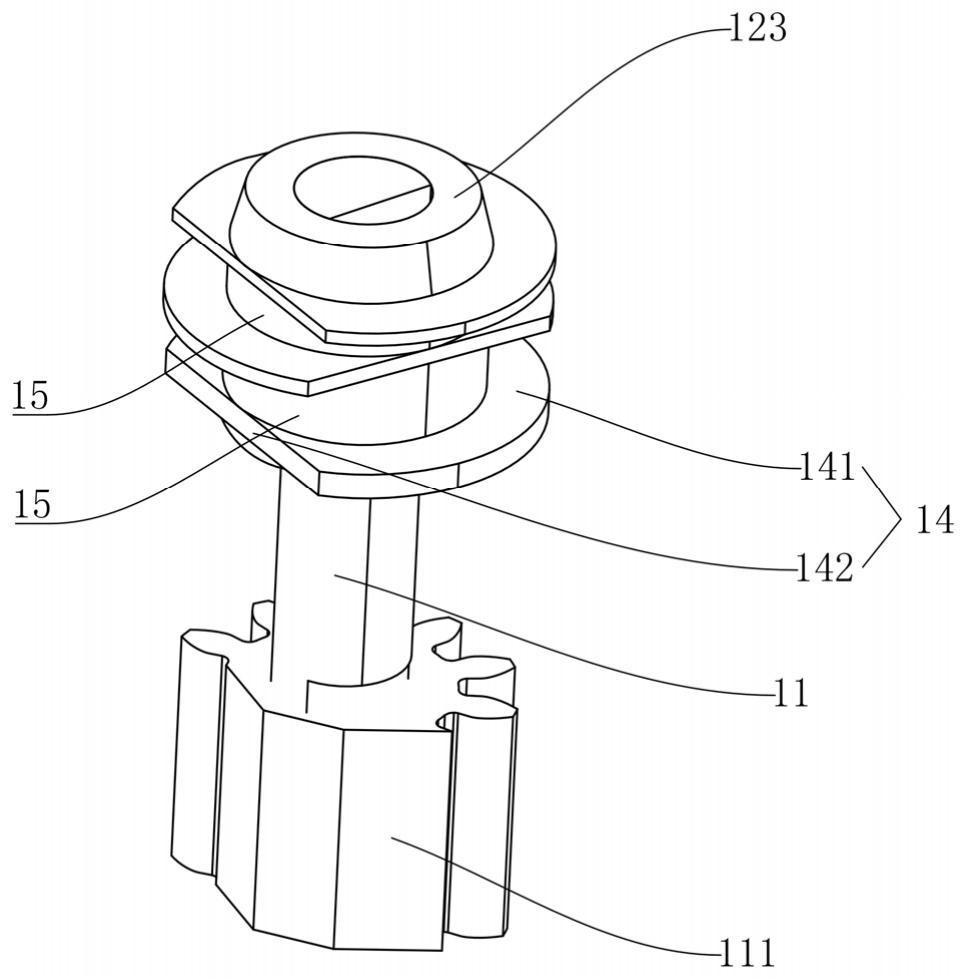

[0034] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

[0035] Such as figure 1 , figure 2 As shown, a rotary dislocation blanking structure includes a supporting block 1 and a driving member 2. The supporting block 1 includes a rotating shaft 11, a first supporting piece 12, a second supporting piece 13, a first supporting piece 12, a second supporting piece Sheets 13 are sequentially stacked on the rotating shaft 11, the first supporting sheet 12 includes a first supporting portion 121 for supporting materials and a first blanking portion 122 for discharging materials, and the second supporting sheet 13 includes a first supporting portion 122 for supporting materials. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com