Energy-saving air supply system of fuel cell test board

An air supply system, fuel cell technology, applied in fuel cells, electrical components, circuits, etc., can solve problems such as air compressor flow surge, reduce complexity, achieve dynamic testing, and good flow range adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

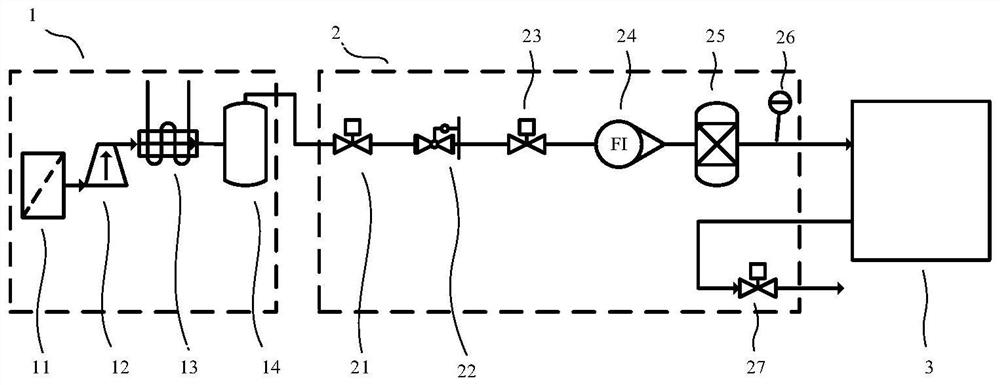

[0038] An energy-saving gas supply system for test benches, such as figure 2 As shown, it includes a main road, and the main road includes an air filter 41, an air compressor 42, a cooler 43, a main road valve 44, a flow meter 45, and a humidifier 46 connected in sequence; The cathode inlet of the stack 3 is connected, and the outlet of the stack 3 is connected with the back pressure valve 49; the system is also provided with a branch circuit, and the branch circuit inlet connection end is arranged between the cooler 43 and the main circuit valve 44, The branch outlet connection end is set between the electric stack 3 and the back pressure valve 49; the branch regulating valve 48 is arranged on the branch.

[0039]Described air compressor 42 is a low-pressure air compressor;

[0040] The stack 3 is arranged outside the test bench;

[0041] A gas detector 47 is also provided between the humidifier 46 and the electric stack 3; it is used to detect air temperature, pressure an...

Embodiment 2

[0052] An energy-saving gas supply system for test benches, such as image 3 shown. Including the main road, the main road includes an air filter 41, an air compressor 42, a cooler 43, a main road valve 44, a flow meter 45, and a humidifier 46 connected in sequence; The outlet of the electric stack 3 is connected to the back pressure valve 49; the system is also provided with a branch, and the inlet connection end of the branch is set between the cooler 43 and the main circuit valve 44, and the branch The outlet connection end of the circuit is set between the electric stack 3 and the back pressure valve 49; the branch circuit regulating valve 48 is provided on the branch circuit.

[0053] Described air compressor 42 is a low-pressure air compressor;

[0054] The stack 3 is arranged outside the test bench;

[0055] A gas detector 47 is also provided between the humidifier 46 and the electric stack 3; it is used to detect air temperature, pressure and humidity.

[0056] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com