Slurry pipe extension system and construction method thereof

A mud pipe and mud technology, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as difficulty in extending mud pipes, and achieve the effect of saving space and ensuring liquid level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

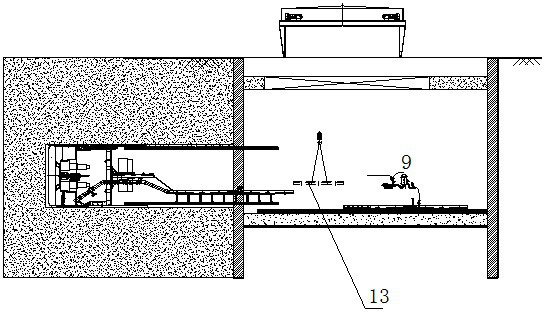

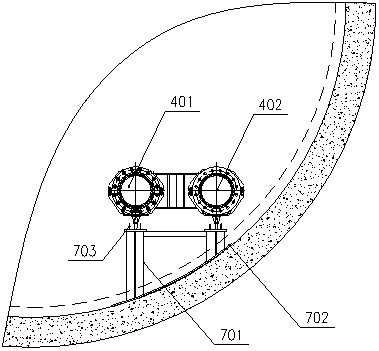

[0045] Example 1, a mud tube extension system, such as Figure 1 - Figure 4 As shown, the punching line and slurry line between the main mud line 101 connected to the motor main unit, including the mud line and the slurry line, including the arrangement in the originating well. The extended hose 8 connected to the mud station, extension of the extended hose 8 extends in the originated well, the extension hose 8 is connected to the host mud pipe 10 by the traveling mud tube 4, and the walking mud hard tube 4 includes walking The feed hard tube 401 and the walking slurry 402.

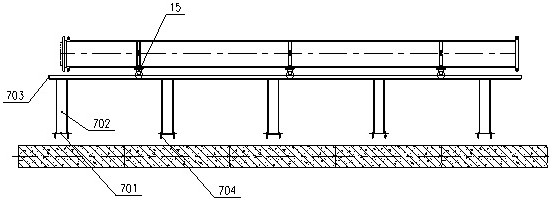

[0046] Such as Figure 5 - Figure 8 As shown, the walking mud hard tube 4 is connected to the traveling unit 15, and the guide bracket 7 of the support travel unit 15 is provided in the originating guide hole, and the motor 1 can be conveniently driven by the guide bracket 7 and the traveling unit 15. The hard tube 4 moves forward, and then the collapsed extended hose 8 is elongated, and the walking mud tube 4...

Embodiment 2

[0051] Example 2, a construction method of a mud tube extension system when a mud water balancing digging machine split is initiated, and the principle is Figure 9 As shown, the construction steps are as follows:

[0052] S1: Put the machine 1, fix the mud tube 11, the slurry unit 9, the extension hose 8, the walking mud hard tube 4, the travel unit 15, the guide bracket 7 complete the underlying surface and complete the installation, according to the length of the extension hose 8 State position one and a predetermined position 2, and the extension hose 8 is located in a predetermined position.

[0053] S2: Open the mud ball valve 6, the first gate valve 10, the second gate valve 16, and closes the ball valve 12, so that the mud stop of the mud station flows into the main chamber of the motor main unit, and when the main chamber mud meets the tunneling requirements of the mud water balance, Start excavation.

[0054] S3: When the extension hose 8 extends to a predetermined posit...

Embodiment 3

[0059] Example 3, a construction method of the mud tube extension system when the mud water balancing digging machine split is initiated, when the earthygo is stopped during the initial time, if the facade is not satisfied, open the punching line The second gate valve 16 turns off the first gate valve 10, opening the ball valve 12 between the sealing unit 9 and the puncturing line, and replenishes the mud to the gas tank, maintaining the facial level of the palm.

[0060] The structure of this embodiment is the same as in Example 1.

[0061] The other steps of the present embodiment are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com