Spiral conveying equipment

A screw conveying and equipment technology, which is applied in the field of screw conveying equipment, can solve the problems of poor airtight and pressure-holding performance of equipment, dust and gas leakage, and lower material temperature, so as to achieve reliable sealing structure performance, reduce temperature drop, and reduce reheating energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the purpose, structure and function of the present invention, a screw conveying device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

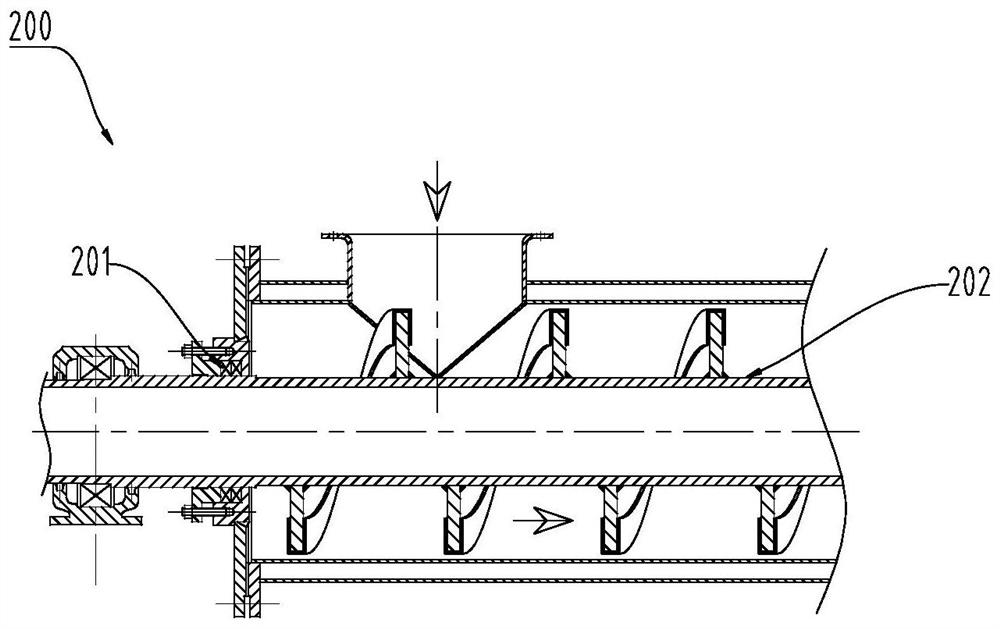

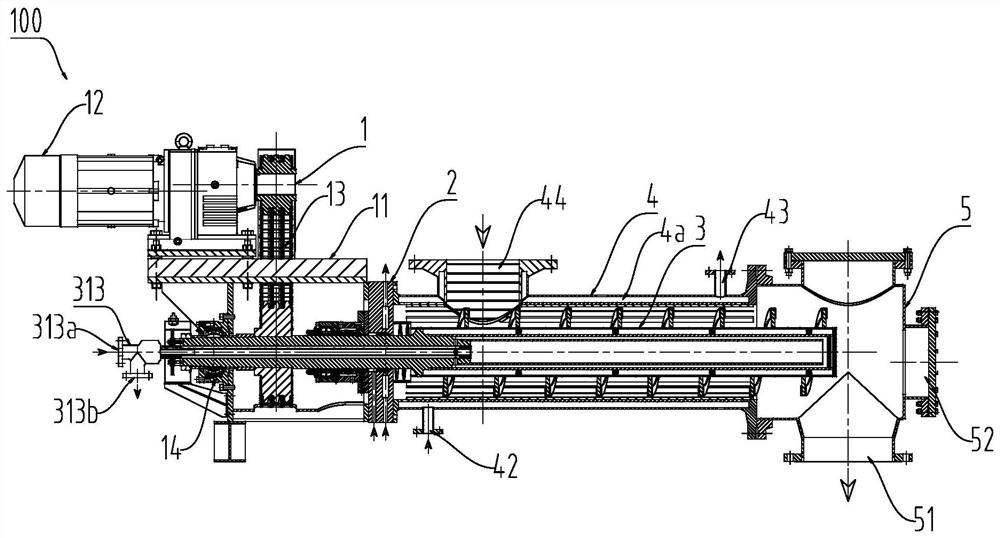

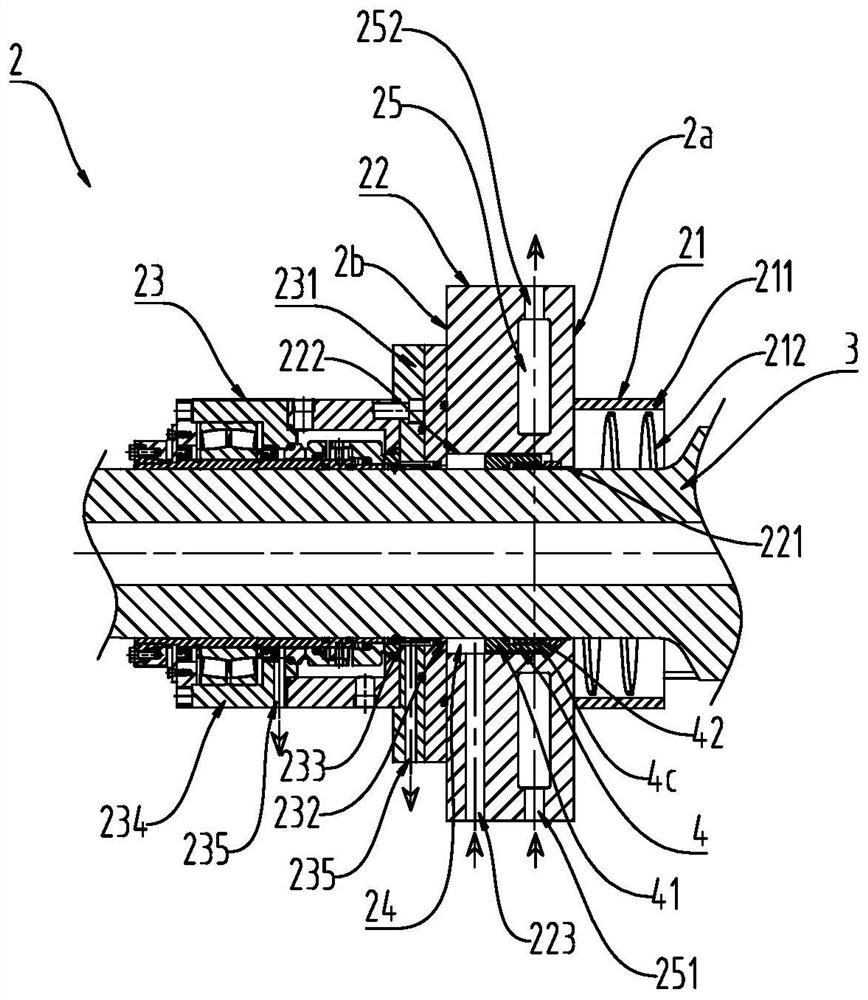

[0025] figure 2 The structure of the screw conveying device 100 according to the embodiment of the present invention is shown. Such as figure 2 As shown, the screw conveying device 100 includes a driving device 1 , a combined sealing device 2 , a screw shaft 3 and a pushing cylinder 4 . Wherein, the screw shaft 3 is coaxially arranged in the pushing cylinder 4 and one end is connected to the driving device 1, and the combined sealing device 2 is sleeved on the screw shaft 3 and is located between the driving device 1 and the pushing cylinder 4, image 3 shows the structure of the combined sealing device 2 according to the embodiment of the present invention, combined with image 3 As shown, the combined sealing device 2 includes a mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com