A processing equipment for removing leather clothing

A technology for processing equipment and leather garments, which is applied in the field of processing equipment for removing leather garments, can solve the problems that the epidermis and rice grains are not easy to separate, affect the processing quality, and the rice grains are easily broken, so as to improve the scope and area of use, avoid magnetic consumption, and ensure The effect of the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

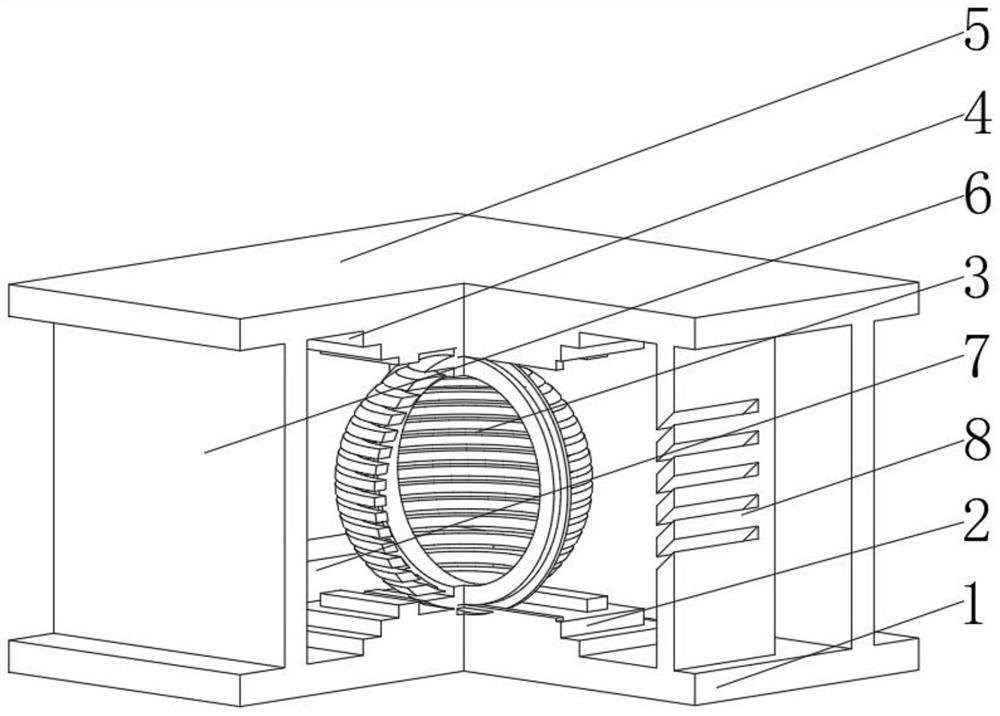

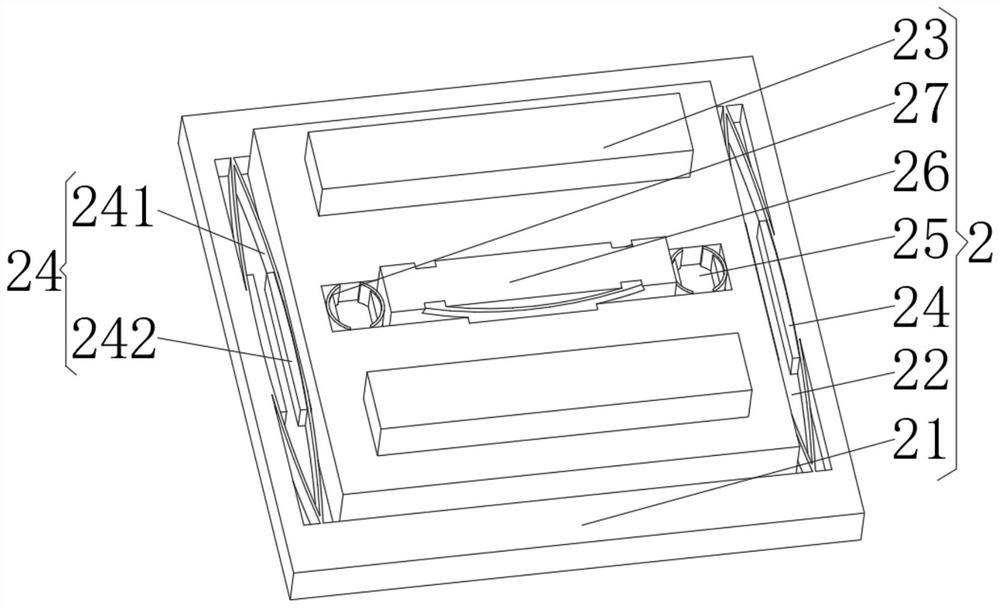

[0036] see Figure 1-5 , the present invention provides a technical solution: a processing equipment for removing leather clothing, comprising a protective seat plate 1, a protective mechanism 2 is fixedly connected at the middle position of the top of the protective seat plate 1, and the protective mechanism 2 is movably connected to one side away from the protective seat plate 1 There is a peeling mechanism 3, the side of the peeling mechanism 3 away from the protection mechanism 2 is fixedly connected with a rebound mechanism 4, and the side of the rebound mechanism 4 away from the peeling mechanism 3 is fixedly connected with a strengthening top plate 5, and the top of the protective seat plate 1 is located at the The front and back of the protective mechanism 2 are fixedly connected with a heat drying mechanism 6 , the top of the protective seat plate 1 is located on the left side of the protective mechanism 2 and a diversion mechanism 7 is fixedly connected, and the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com