Tamping machine for building construction

A technology of building construction and tamping machine, which is used in construction, road, road repair and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

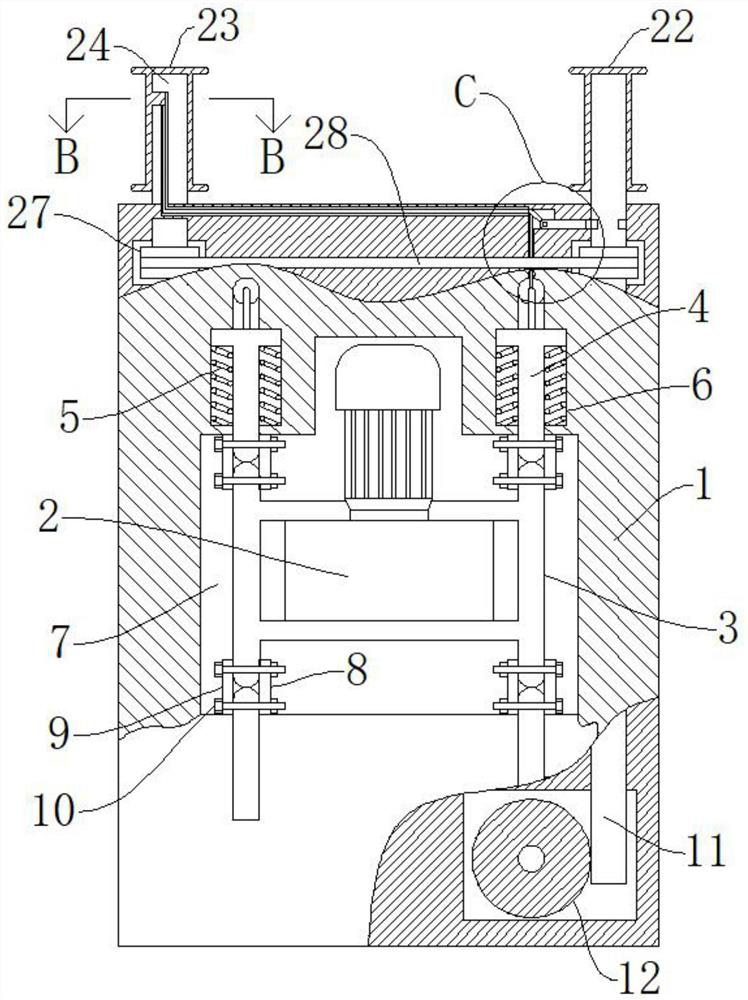

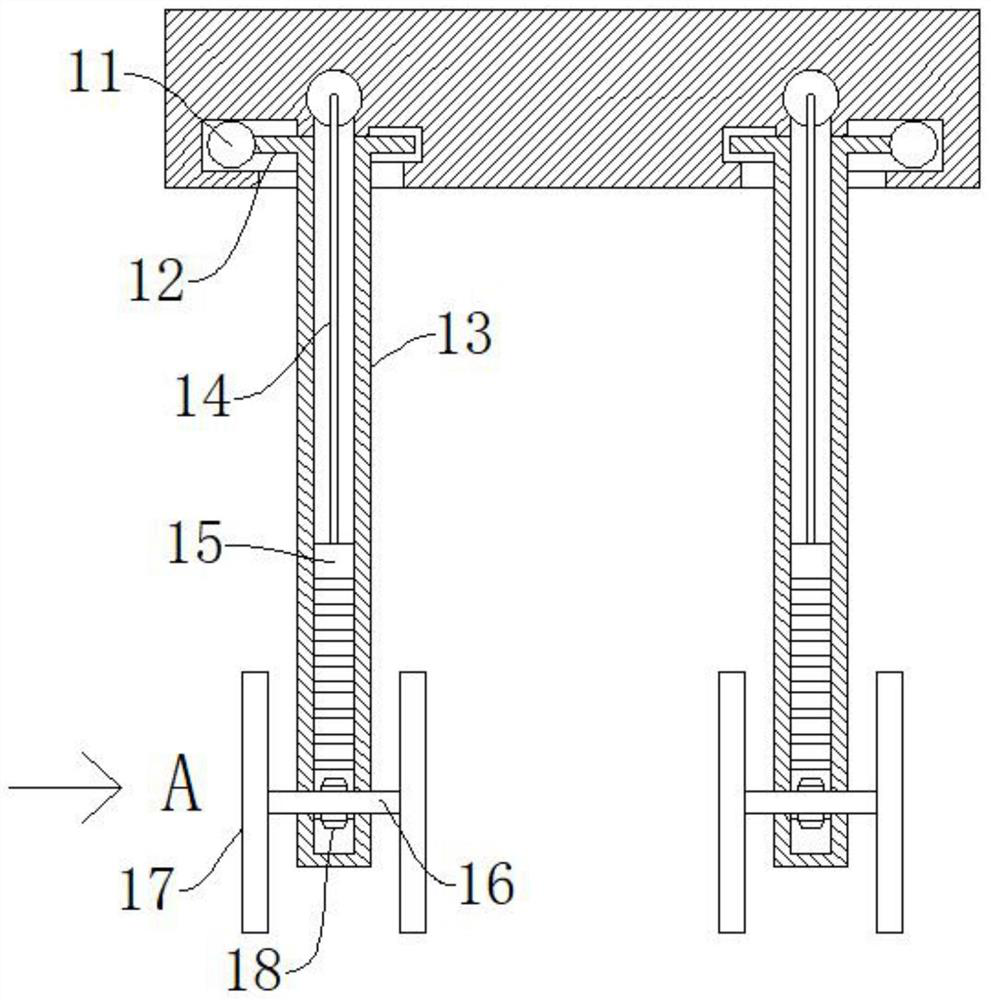

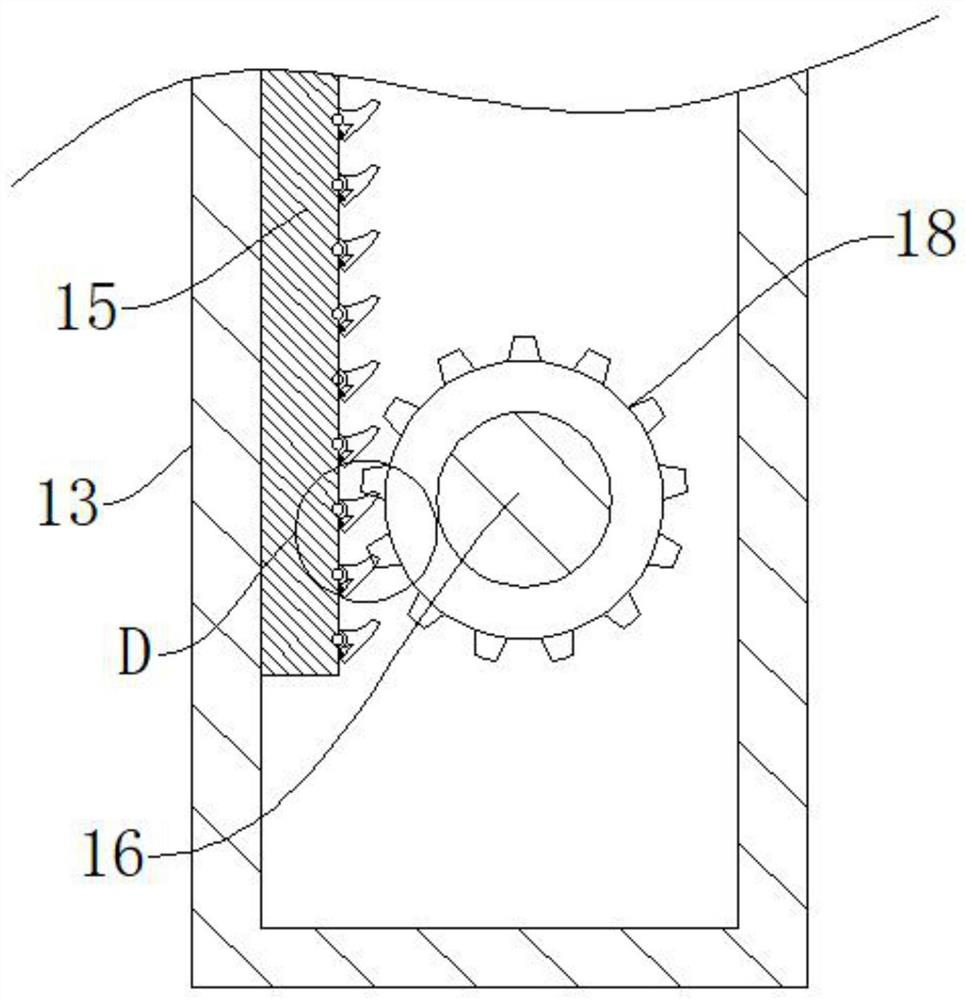

[0034] refer to Figure 1-8 , a kind of tamping machine for construction, comprising a mobile workbench 1, a ramming body 2, a through groove 7 is arranged in the mobile workbench 1, a fixed frame 3 is connected in the through groove 7, and the tamping body 2 is fixedly connected to a fixed In the frame 3, a first support leg 13 is symmetrically connected to one side of the lower end of the mobile workbench 1, and a second support leg 34 is fixedly connected to the side far away from the first support leg 13 at the lower end of the mobile workbench 1. The lower ends of the two support legs 34 are all rotatably connected with a rotating wheel 17 .

[0035] When using the device, at first the device is moved to the place of use, in order to move the device to the place of use conveniently, the first guard 22 and the second guard 23 can be held to push the device, because the first supporting legs 13, The lower ends of the second supporting legs 34 are all connected with the rot...

Embodiment 2

[0041] refer to figure 1 , Figure 7 , a kind of tamping machine for building construction, which is basically the same as that of Embodiment 1, and furthermore, a plurality of sets of sliding grooves 6 are arranged in the mobile workbench 1, sliding plates 4 are slidably connected in the sliding grooves 6, and sliding plates 4 are slidably connected in the sliding grooves 6. The first thrust spring 5 is symmetrically connected, and the two ends of the first thrust spring 5 are fixedly connected with the sliding groove 6 and the mobile worktable 1 respectively, and the sliding plate 4 is connected with the fixed frame 3, so as to absorb the vibration generated by the tamping body 2 .

Embodiment 3

[0043] refer to figure 1 , a ramming machine for building construction, which is basically the same as Embodiment 1, and furthermore: includes fastening bolts 10, and the two sides of the fixed frame 3 are respectively connected with a first fixed plate 8, a second fixed plate 9, the first fixed plate One side of the fixed plate 8 and the second fixed plate 9 away from the fixed frame 3 is connected with the sliding plate 4, and the first fixed plate 8 and the second fixed plate 9 are connected with the sliding plate 4 and the fixed frame 3 by fastening bolts 10, One end of the fastening bolt 10 is connected with a fastening nut, and the fixed frame 3 and the sliding plate 4 are all rotatably connected with the fastening bolt 10, so that the fixed frame 3 and the sliding plate 4 are connected conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com