Water seepage system for sponge city

A sponge city and water-liquid technology, applied in waterway systems, sewage removal, water supply devices, etc., can solve the problems of poor structural strength and short service life of permeable bricks, and achieve the effect of avoiding water accumulation and restoring ecological damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

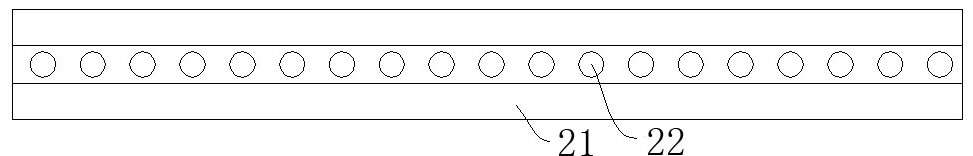

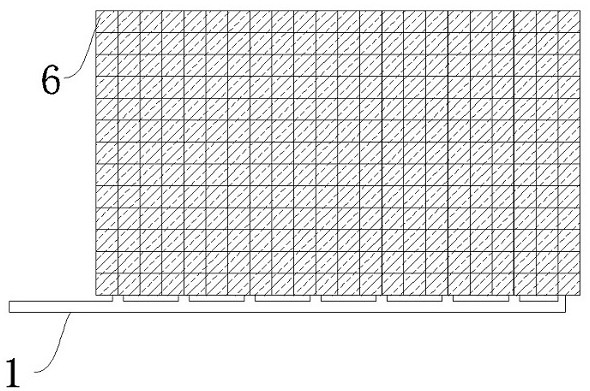

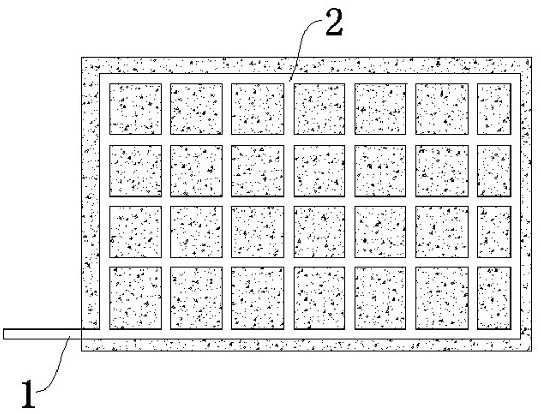

[0039] like figure 1 and figure 2 As shown, a water seepage system for a sponge city includes a water seepage blind ditch 2, a water seepage cover plate and a surface layer 6, the water seepage blind ditch 2 converges into a network structure, and a number of water seepage blind ditch 2 is opened on the base layer 9, and the water seepage blind ditch 2 Covered by the seepage cover plate, and the seepage joint 5 where the water liquid flows into the seepage blind ditch 2 is left on the seepage cover plate, and the surface layer 6 is laid on the seepage cover plate, and the surface layer 6 is left corresponding to the seepage joint 5 The water liquid on the surface layer 6 flows into the seepage blind ditch 2 through the stitching seam and the water seepage joint 5 successively.

[0040] In this example, if Image 6 As shown, a plain soil layer 17 is laid on the base layer 9 in the seepage blind ditch 2, a second water seepage layer 11 is laid on the plain soil layer 17, a fi...

Embodiment 2

[0049] like figure 1 and figure 2 As shown, a water seepage system for a sponge city includes a water seepage blind ditch 2, a water seepage cover plate and a surface layer 6, the water seepage blind ditch 2 converges into a network structure, and a number of water seepage blind ditch 2 is opened on the base layer 9, and the water seepage blind ditch 2 Covered by the seepage cover plate, and the seepage joint 5 where the water liquid flows into the seepage blind ditch 2 is left on the seepage cover plate, and the surface layer 6 is laid on the seepage cover plate, and the surface layer 6 is left corresponding to the seepage joint 5 The water liquid on the surface layer 6 flows into the seepage blind ditch 2 through the stitching seam and the water seepage joint 5 successively.

[0050] In this example, if Figure 12 As shown, a plain soil layer 17 is laid on the base layer 9 in the seepage blind ditch 2, a second water seepage layer 11 is laid on the plain soil layer 17, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com