Rolling supporting mechanism for drying printed and dyed silk fabrics

A rolling support, silk fabric technology, applied in textiles and papermaking, textile material processing, winding strips, etc., can solve problems such as affecting the drying effect of cloth, easily polluting the surrounding environment, and inconvenient for cloth winding, and achieves increased practicality. The effect of flexibility, convenient winding and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

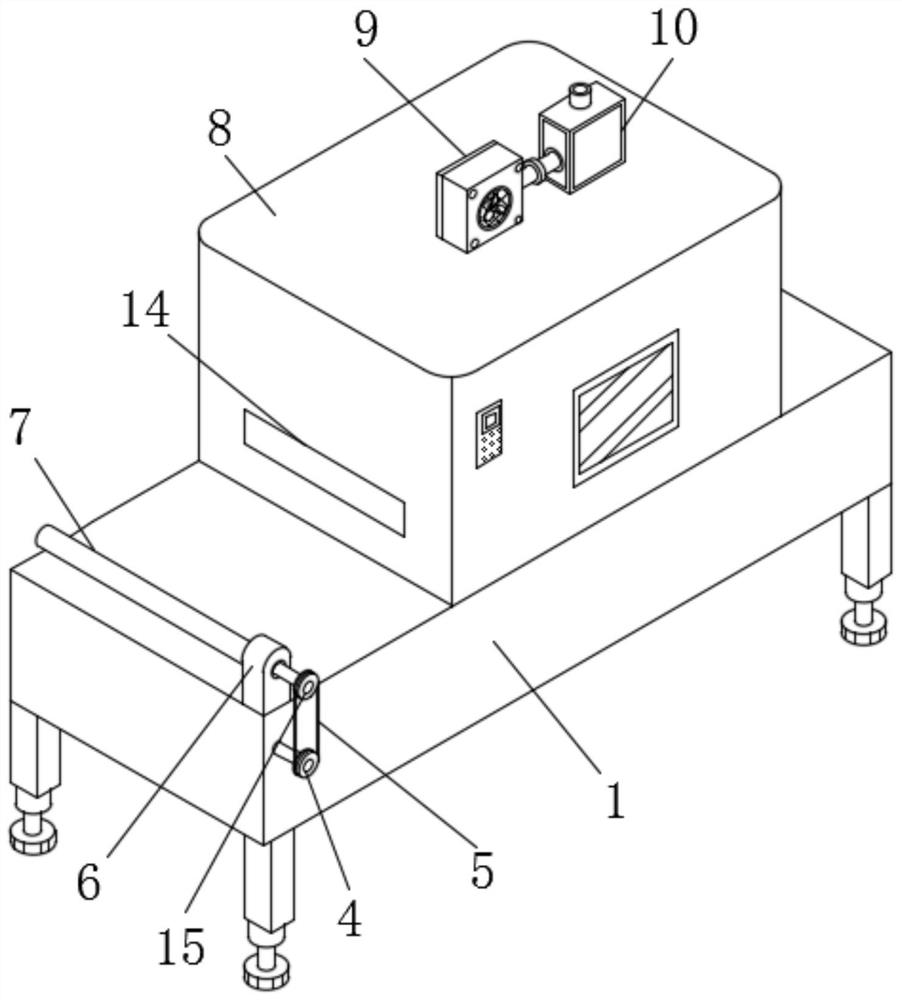

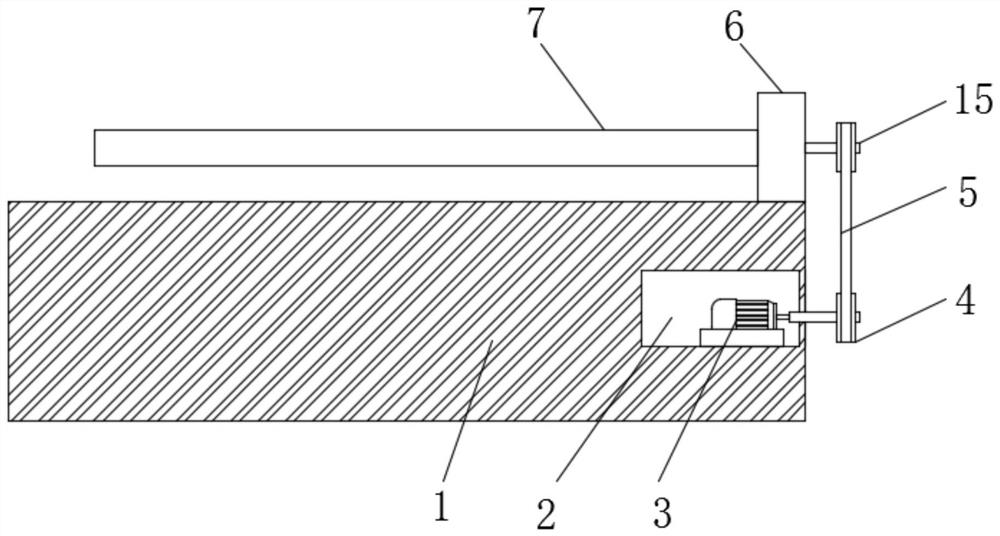

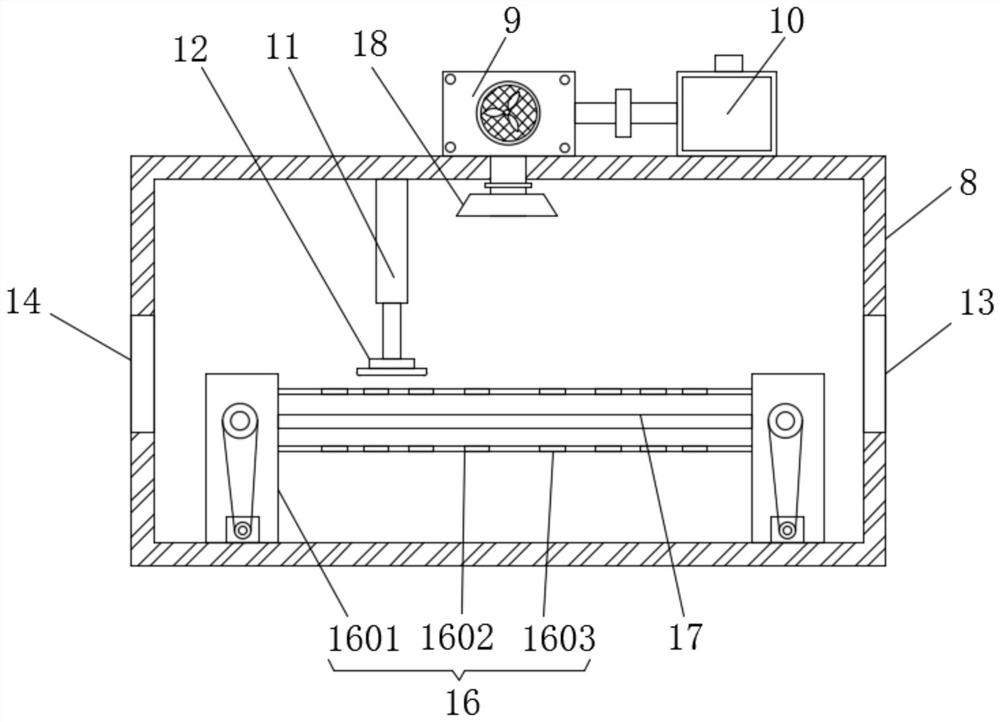

[0023] An embodiment provided by the present invention: a rolling support mechanism for drying printed and dyed silk fabrics, including a workbench 1 and a cavity 2, a cavity 2 is opened inside the workbench 1, and a first Motor 3, the output end of the first motor 3 is provided with a driving wheel 4, the surface of the driving wheel 4 is connected to the first conveyor belt 5, the upper surface of the workbench 1 is provided with a mounting block 6, and the inside of the mounting block 6 is inserted with a coil The cloth drum 7, the upper surface of the workbench 1 is provided with a drying box 8, the upper surface of the drying box 8 is fixedly equipped with an exhaust fan 9, one side of the exhaust fan 9 is fixedly connected with a pipeline, and one end of the pipeline is provided with a filter box 10 , through the setting of the exhaust fan 9 and the filter box 10, the exhaust fan 9 sucks away the water vapor generated by drying the cloth through the suction head 18, which...

Embodiment 2

[0025] On the basis of Example 1, please refer to Figure 1-4 , Another embodiment provided by the present invention: a rolling support mechanism for drying printed and dyed silk fabrics, including a workbench 1 and a cavity 2, the inside of the workbench 1 is provided with a cavity 2, and the inside of the cavity 2 is fixedly installed with The first motor 3, the output end of the first motor 3 is provided with a drive wheel 4, the surface of the drive wheel 4 is connected to the first conveyor belt 5, the upper surface of the workbench 1 is provided with a mounting block 6, and the interior of the mounting block 6 is plugged There is a cloth rolling drum 7, a drying box 8 is arranged on the upper surface of the workbench 1, an exhaust fan 9 is fixedly installed on the upper surface of the drying box 8, and a pipeline is fixedly connected to one side of the exhaust fan 9, and a filter is installed at one end of the pipeline. box 10, through the setting of the exhaust fan 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com