Walnut chip boxing equipment

A technology of walnut slices and boxing, applied in the field of packaging, can solve the problems of poor sealing effect and incomplete sealing of packaging boxes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

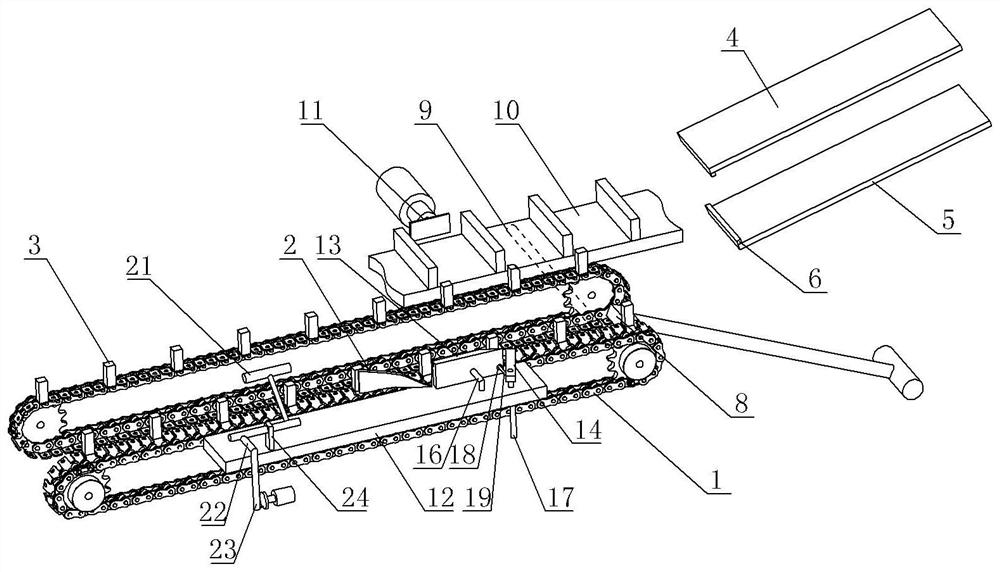

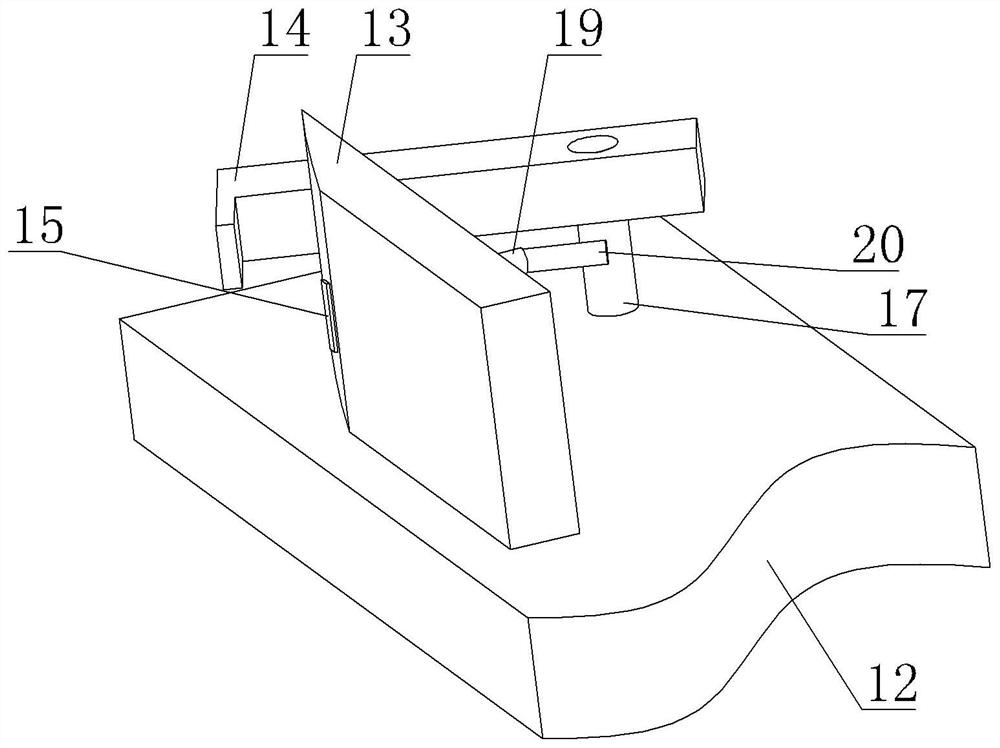

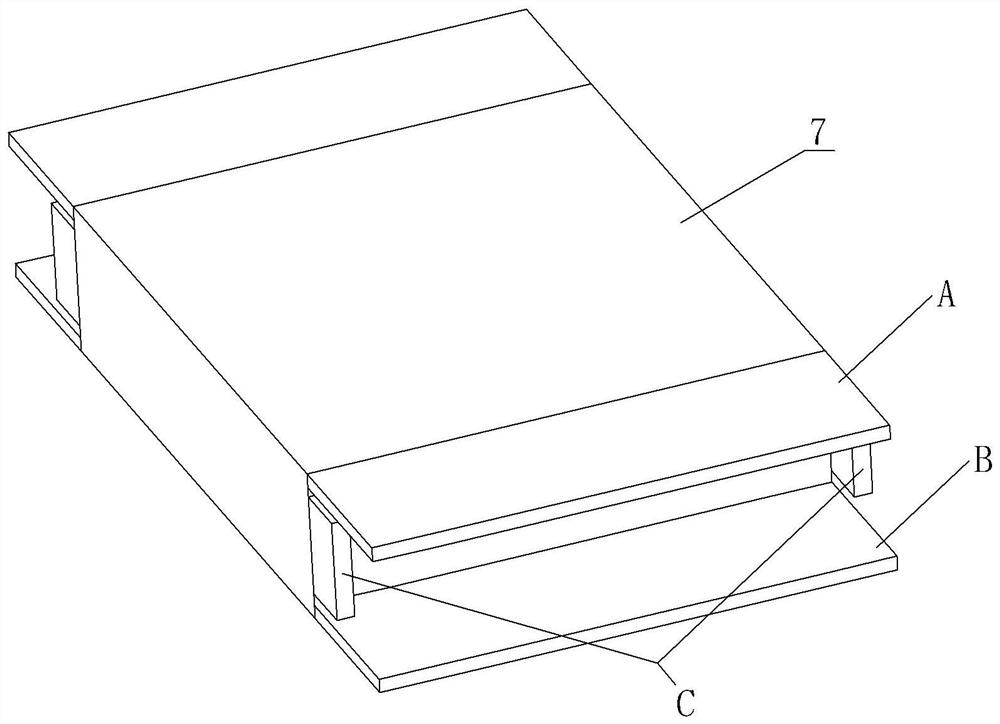

[0020] The example is basically as attached Figure 1-3 shown: as figure 1 The shown cartoning equipment for walnut slices includes a rack, a carton feeding mechanism, a feeding mechanism and two cartoning mechanisms, each of which includes a conveying chain 1 and a side ear folding unit and a lower ear folding unit located outside the conveying chain 1. Block 2 and upper ear folding unit (wherein the side ear folding unit, lower ear folding block 2 and upper ear folding unit located on the rear side of the rear conveyor chain 1 are not shown, and the side ear folding unit located on the front side of the front conveyor chain 1 has been shown. The unit, the lower ear folding block 2 and the upper ear folding unit have the same settings, except that the positions of the side ear folding unit, the lower ear folding block 2 and the upper ear folding unit in the two cartoning mechanisms are staggered). 3.

[0021] The box feeding mechanism includes a box storage unit and an adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com