Electronic power-assisted braking system with redundancy

An electronic power assist and braking system technology, applied in the direction of braking safety systems, brakes, braking transmissions, etc., can solve the problems of increasing the cost of large vehicles, unfavorable product competitiveness, and insufficient safety redundancy, so as to ensure foot safety Consistency, cost savings, and support for large liquid needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

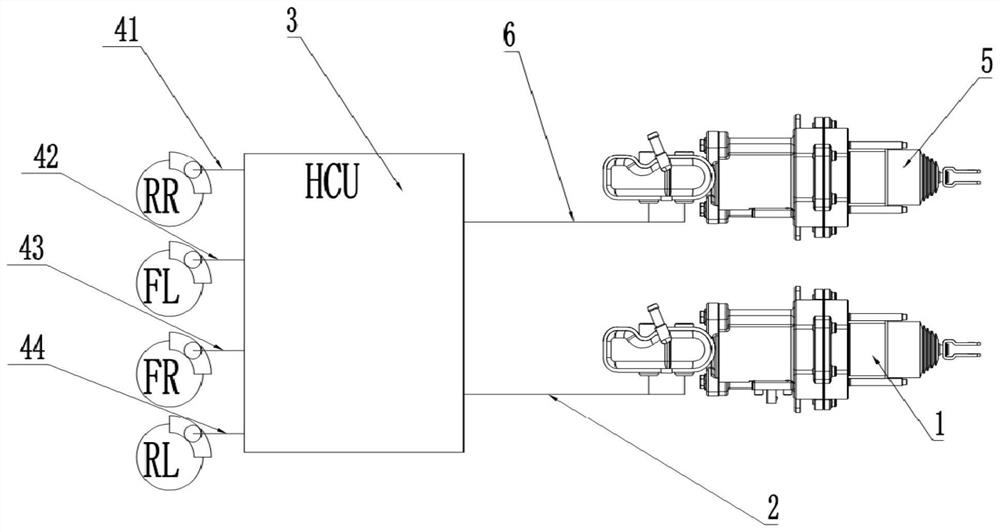

[0012] Embodiment: As shown in the accompanying drawings, this electronic power-assisted braking system with redundancy mainly includes electric power-assisted braking main system 1, main oil inlet pipeline 2, body 3, brake pipeline A41, brake pipeline B42, brake pipeline C43, brake pipeline D44, electric booster brake slave system 5, slave oil inlet pipeline 6, the body 3 is connected with brake pipeline A41, brake pipeline B42, brake pipeline C43 , Brake pipeline D44, the electric power-assisted braking main system 1 is connected to the main body 3 through the main oil inlet pipeline 2, and the brake fluid is distributed to the brake pipeline A41, brake pipeline B42 through the main body 3, the electric power-assisted braking The driven-slave system 5 is connected to the main body 3 through the slave oil inlet pipeline 6, and distributes the brake fluid to the brake pipeline C43 and the brake pipeline D44 through the main body 3. The electric power assist braking main system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com