Screening device for waste rock processing

A screening device and sieve plate technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of inability to crush stone, reduce work efficiency, blockage of waste stone of filter plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

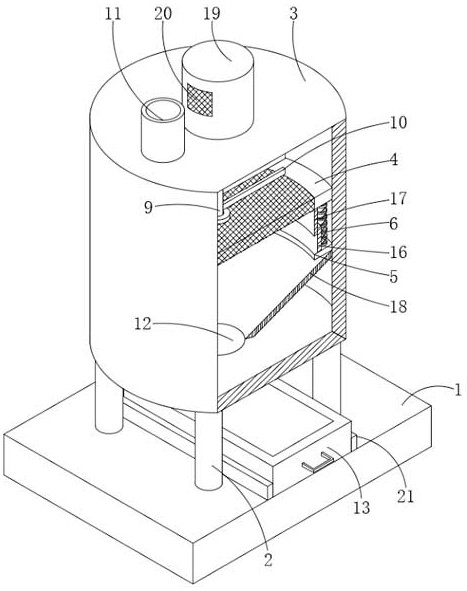

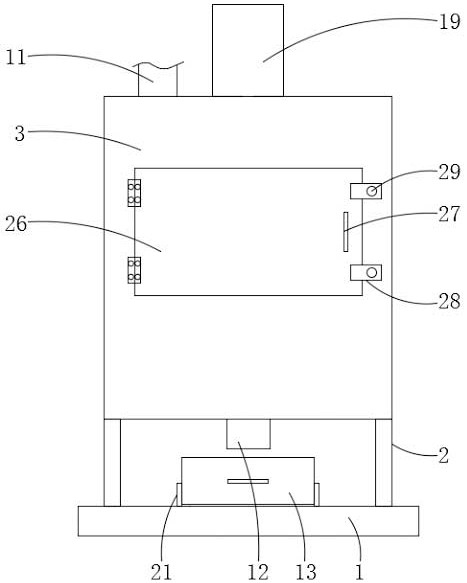

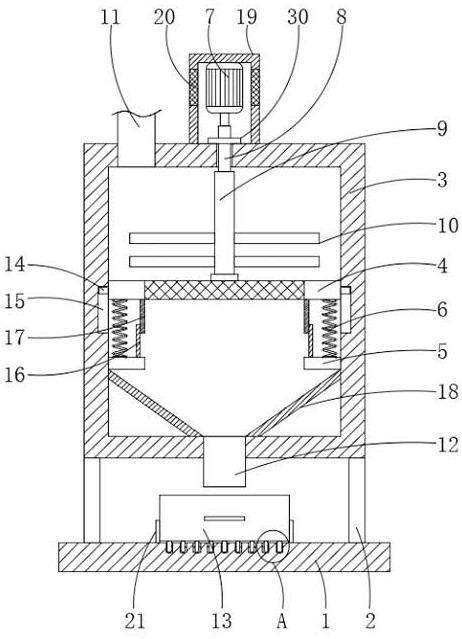

[0028] see Figure 1-6 , the present invention provides a technical solution: a screening device for waste rock processing, comprising a base 1, the four corners of the top of the base 1 are fixedly installed with a pillar 2, the top of the pillar 2 is fixedly installed with a crushing box 3, and the inside of the crushing box 3 The cavity is provided with a sieve plate 4, the inner wall of the crushing box 3 and the bottom of the sieve plate 4 are fixedly installed with a fixed plate 5, and the top of the fixed plate 5 is equidistantly fixed with a spring 6, and the top of the spring 6 is fixed to the bottom of the sieve plate 4 Installation, the top of the crushing box 3 is provided with a motor 7, the output shaft of the motor 7 is fixedly installed with a rotating rod 8, and the bottom of the rotating rod 8 runs through the crushing box 3 and extends to the inner cavity of the crushing box 3. , both sides of the rotating rod 8 and located in the inner cavity of the rotatin...

Embodiment 2

[0031] see Figure 1-6The difference between the present embodiment 2 and the embodiment 1 is that: both sides of the sieve plate 4 are fixedly installed with a limit block 14, and the inner wall of the crushing box 3 is provided with a limit groove 15 that is compatible with the limit block 14. The surface of the position block 14 is slidingly connected with the inner wall of the limiting groove 15, the top of the fixed plate 5 and one side of the spring 6 are fixedly installed with a first sealing tube 16, and the inner wall of the first sealing tube 16 is slidingly connected with a second sealing tube 17. The top of the second sealing pipe 17 is fixedly installed with the bottom of the sieve plate 4, and the inner cavity of the crushing box 3 is fixedly installed with a deflector 18 at the bottom of the fixed plate 5, and the bottom of the deflector 18 is connected with the inside of the crushing box 3. The bottom of the cavity is fixedly installed, and the deflector 18 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com