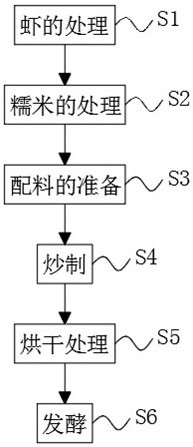

Production process of shrimp sauce

A production process, technology of shrimp paste, applied in the field of production process of shrimp paste, can solve the problems of unstable quality, long preparation cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]S1, shrimp treatment: Select 17 skin shrimp shells and 17 coprus shells, cleaning the selected leather shrimp shell and the shrimp shell, select the high-quality leather shrimp shell and the shrimp shell, then put the leather shrimp Shell and the shrimp shell are placed in the dryer for drying. After drying, it will take it into powder, over 100 mesh sieve, select 13 shrimps, and put the shrimp and water according to the number of parts by weight 1: 3 ratio mixing Soaked for 30 minutes, filter out the water, remove the shrimp chopper, the shrimp particles are less than 2 mm, then add 8 parts of salt salts, use the mixer to completely mix well, use a meat grinder, combined with salt, mix, uniform, smash, Dressing multiple times, then add the leather shrimp shell and the shrimp powder, mix it evenly;

[0025]S2, glutinous rice treatment: Select 15 high quality glutinous rice, after soaking it for 2 days, clean it clean, then the glutinous rice is powdered, add a small amount of war...

Embodiment 2

[0031]S1, shrimp treatment: 15 pieces of leather shrimp shells and 15 to the shrimp shell, cleaning the selected leather shrimp and screen, select the high-quality leather shrimp shell and the shrimp shell, then put the leather shrimp The shell and the shrimp shell are placed in the dryer for drying. After drying is completed, it is removed into powder, over 100 mesh sieve, selects 10 shrimps, and puts the shrimp and water according to the weight of the weight 1: 3 ratio mixing Soak for 20 minutes, filter out the water, remove the shrimp chopper, the shrimp particles are less than 2mm, then add 6 food salts, use the mixer to mix well, use a meat grinder, combined with salt, mix, uniform, smash the shrimp, Dressing multiple times, then add the leather shrimp shell and the shrimp powder, mix it evenly;

[0032]S2, glutinous rice treatment: Select 10 high quality glutinous rice, after soaking it for 1 day, clean it clean, then put the glutinous rice is powdered, add a small amount of warm...

Embodiment 3

[0038]S1, shrimp treatment: 20 pieces of leather shrimp shells and 20 coprus shells, cleaning the selected leather shrimp shell and the shrimp shell, select the high-quality leather shrimp shell and the shrimp shell, then put the leather shrimp The shell and the shrimp shell are placed in the dryer. After drying, the drying is removed into powder, over 100 mesh sieve, select 15 shrimps, put the shrimp and water by weight 1: 3 ratio 3 For 40 minutes, it is filtered off the water, takes out the shrimp chopper, the shrimp particles are less than 2 mm, then add 10 food salts, use the mixer to completely mix well, use a meat grinder, combined with the salt, mix, uniform, smash, Dressing multiple times, then add the leather shrimp shell and the shrimp powder, mix it evenly;

[0039]S2, glutinous rice treatment: Select 0 high quality glutinous rice, after soaking it for 3 days, clean it clean, then put glutinous rice is powdered, add a small amount of warm water to glutinous rice, temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com