A rope-driven harvesting robot end effector

An end effector and picking robot technology, applied in the field of robotics, can solve problems such as unreasonable structural design, unobvious economic benefits, and unclear economic benefits, and achieve the effects of improved grasping success rate, good passability, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

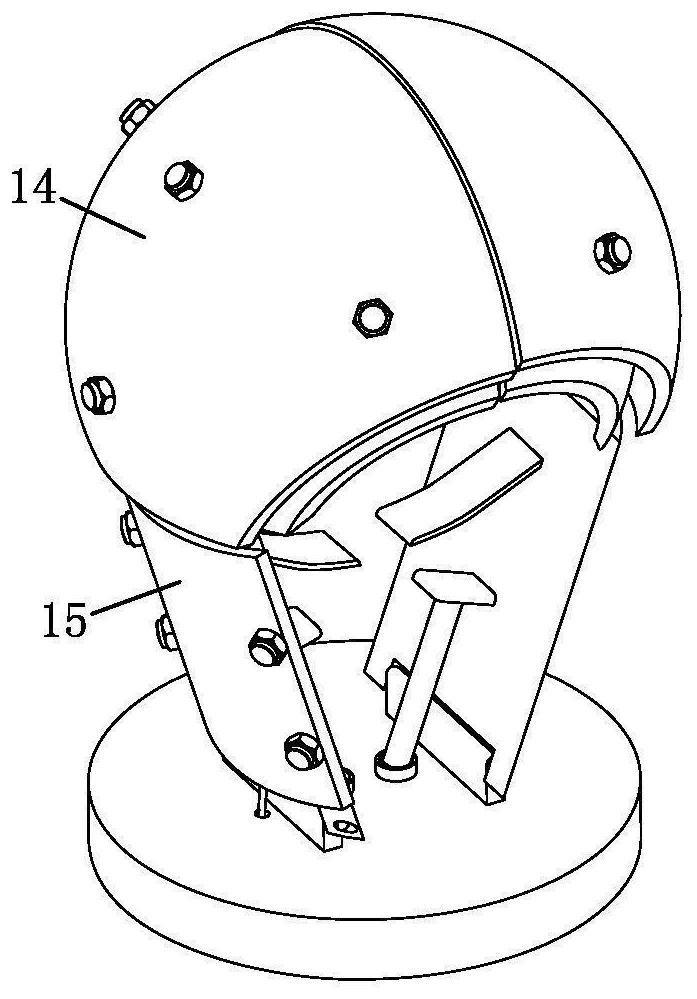

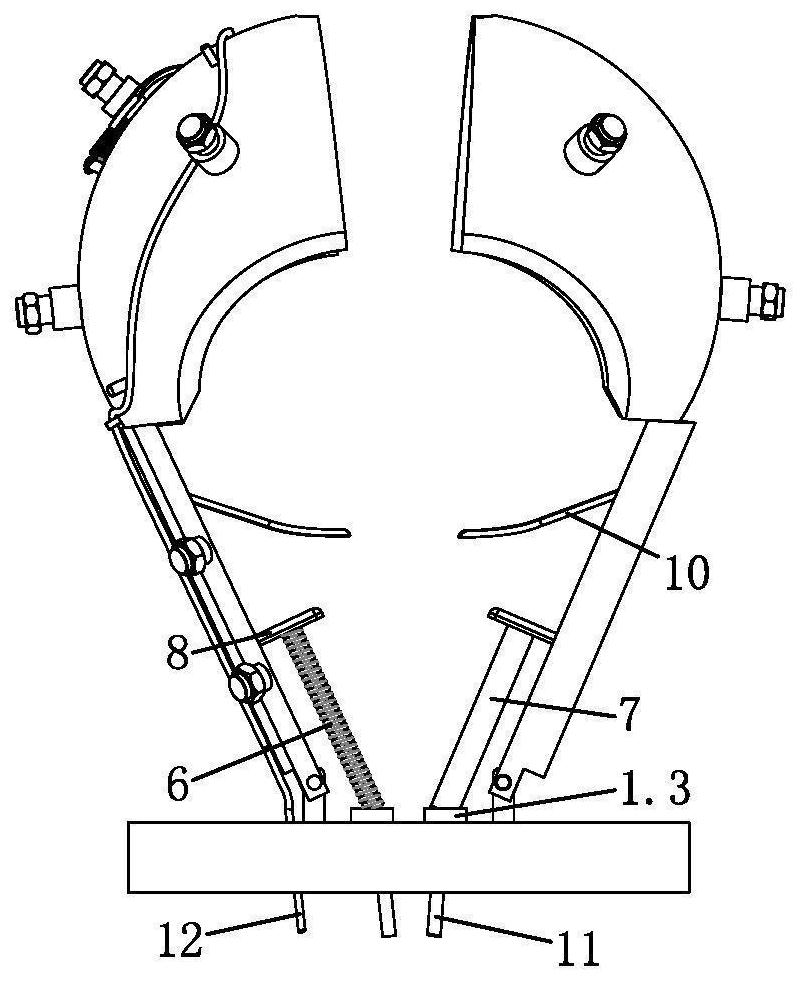

[0032] An end effector of a rope-driven picking robot, comprising a base 1, a pair of grippers, a cutter 4, two first rope-driven mechanisms, and a second rope-driven mechanism. The gripper is set on the base, the cutter is rotatably positioned on the gripper, the first rope drive mechanism is used to drive the gripper to open and close to grab the fruit, and the second rope drive mechanism is used to drive the cutter to rotate to cut fruit stem.

[0033] The base is disc-shaped, and the base is provided with two first through holes 1.1 and a second through hole 1.2 penetrating through the thickness direction. There are two supporting platforms 1.4, and pin shafts 1.5 are arranged on both sides of each supporting platform. The two support platforms are arranged symmetrically to the center of the chas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com