Manufacturing method of tooth beautifying braces

A manufacturing method and technology of braces, which are applied in dentistry, orthodontics, dental prosthetics, etc., can solve the problems that the aesthetic layer is easy to dissolve and the structure is easy to separate, and achieve the effect of good integrity, avoiding dissolution, and not easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

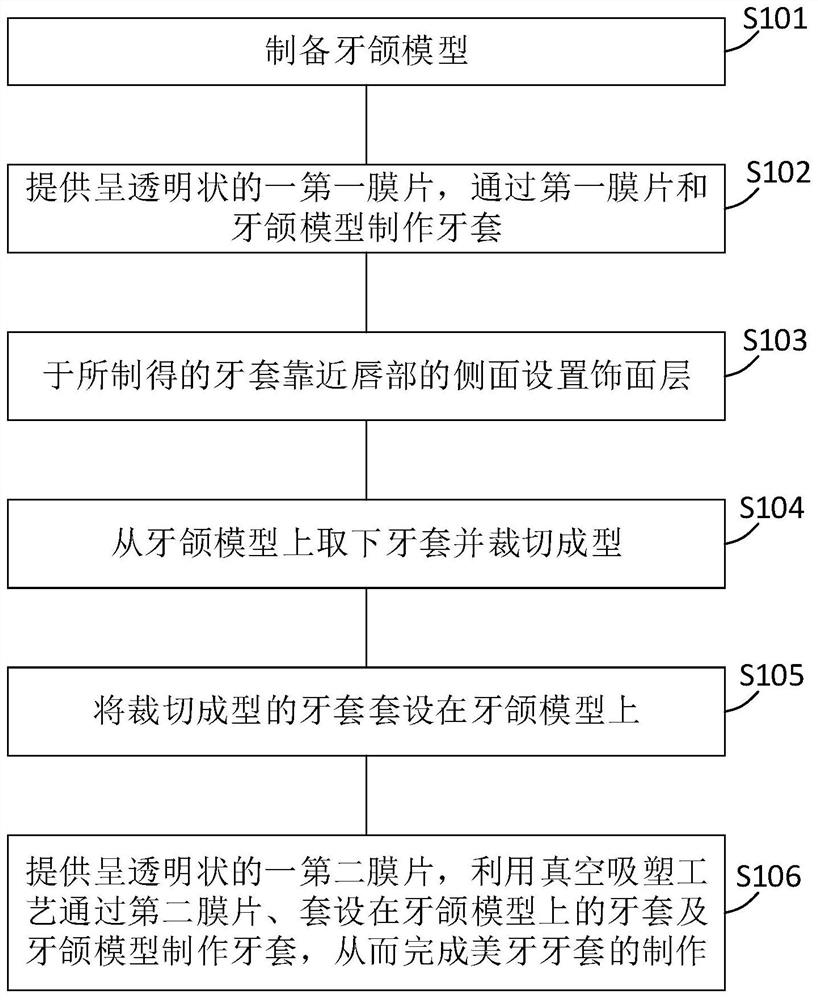

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

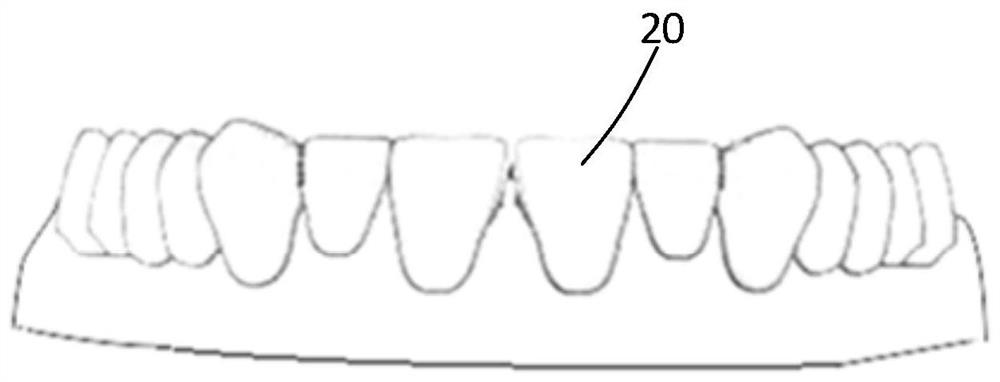

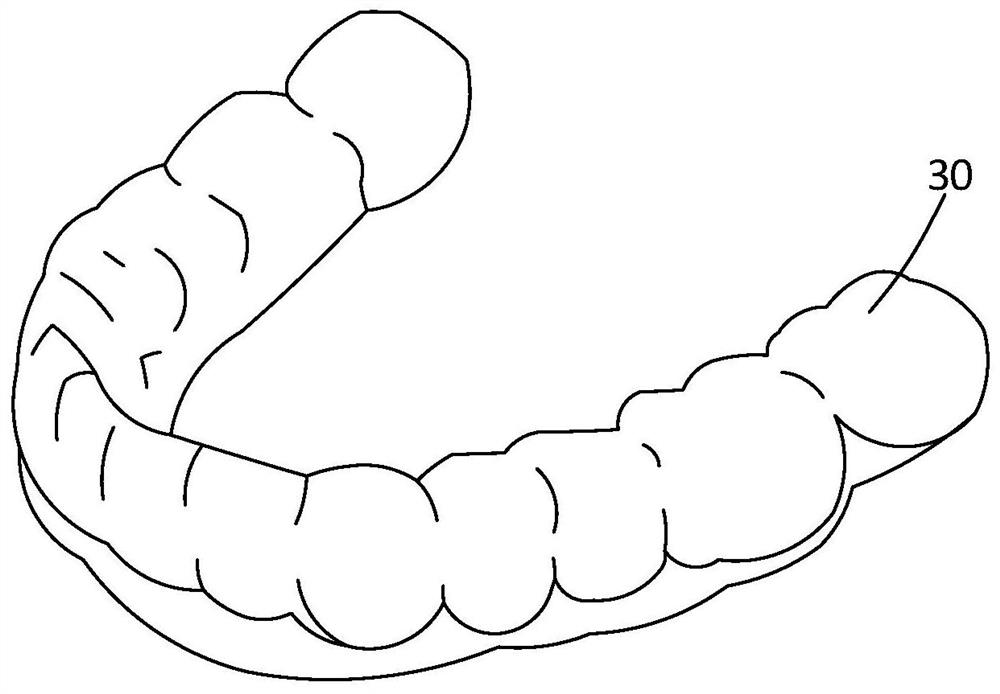

[0031] refer to figure 1 , the present invention provides a method for manufacturing dental braces, which is used to prepare dental braces with cosmetic functions. The cosmetic function is improved by setting a decorative layer on the dental braces. Requirements include whitening, personalized colors, personalized patterns, inlaid diamonds, covering tooth defects and special shape decoration of teeth, etc. The manufacturing method of the present invention adopts two layers of films, and the cosmetic braces are made through the two-layer plastic-absorbing process. The veneer layer is sandwiched between the two layers of films, and the veneer layer can be effectively protected by the two layers of films to ensure the The finish layer provides a cosmetic function with permanence. In addition, the veneer layer is only provided on the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com