Rapid and efficient device and method for extracting micro-plastics in soil

An extraction device and microplastics technology, applied in the field of rapid and efficient extraction of microplastics in soil, can solve the problems of not fully reflecting the real content, difficult to achieve ideal extraction effect, uneven distribution of microplastics, etc., to achieve filtering effect Better, reduce the amount of clogged mesh, improve the effect of filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

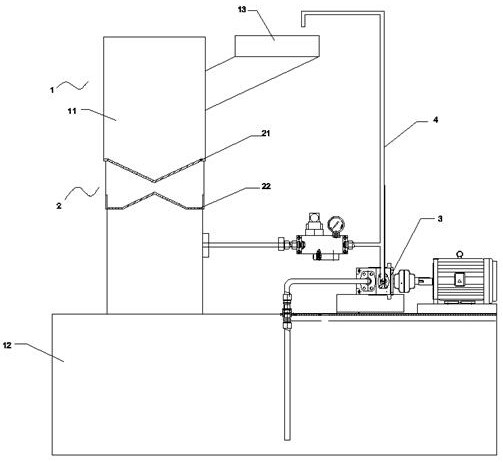

[0032] Such as figure 1 A fast and efficient extraction device for microplastics in soil is shown, including a mud washing cylinder 1, a screen set 2, a circulation pump 3, a circulation pipeline 4 and a microplastic collector.

[0033] The mud washing cylinder 1 includes a mixing channel 11 and a mud tank 12; the mixing channel 11 is arranged vertically and communicates with the upper surface of the mud tank 12; the top of the mixing channel 11 is provided with a water inlet, and the side of the mixing channel 11 The mud inlet 13 is connected with the pipeline; the mud tank 12 is a cuboid shell structure, and the top of the mud tank 12 has an opening connected with the mixing channel, and the side of the mud tank 12 has a circulation port; the inner wall of the mixing channel 11 is also A stepped surface structure supporting the screen group 2 is provided;

[0034] There are several screen groups 2 and are arranged in the mud washing cylinder 1 from top to bottom.

[0035] ...

Embodiment 2

[0046] Such as figure 1 A fast and efficient extraction device for microplastics in soil is shown, including a mud washing cylinder 1, a screen set 2, a circulation pump 3, a circulation pipeline 4 and a microplastic collector.

[0047] The mud washing cylinder 1 includes a mixing channel 11 and a mud tank 12; the mixing channel 11 is arranged vertically and communicates with the upper surface of the mud tank 12; the top of the mixing channel 11 is provided with a water inlet, and the side of the mixing channel 11 The mud inlet 13 is connected with the pipeline; the mud tank 12 is a cuboid shell structure, and the top of the mud tank 12 has an opening connected with the mixing channel, and the side of the mud tank 12 has a circulation port; the inner wall of the mixing channel 11 is also A stepped surface structure supporting the screen group 2 is provided;

[0048] There are several screen groups 2 and are arranged in the mud washing cylinder 1 from top to bottom.

[0049] ...

Embodiment 3

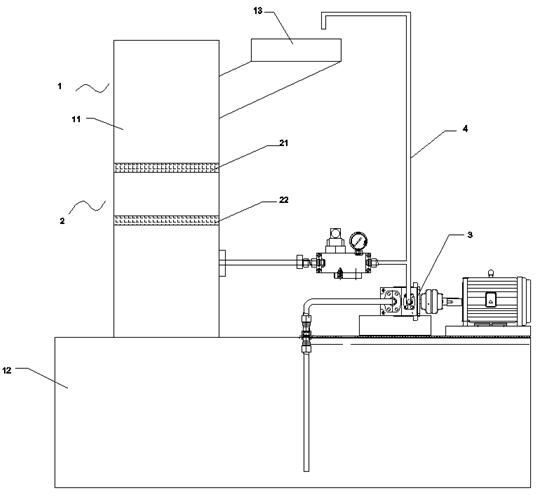

[0060] Such as figure 2 A fast and efficient extraction device for microplastics in soil is shown, including a mud washing cylinder 1, a screen set 2, a circulation pump 3, a circulation pipeline 4 and a microplastic collector.

[0061] The mud washing cylinder 1 includes a mixing channel 11 and a mud tank 12; the mixing channel 11 is arranged vertically and communicates with the upper surface of the mud tank 12; the top of the mixing channel 11 is provided with a water inlet, and the side of the mixing channel 11 The mud inlet 13 is connected with the pipeline; the mud tank 12 is a cuboid shell structure, and the top of the mud tank 12 has an opening connected with the mixing channel, and the side of the mud tank 12 has a circulation port; the inner wall of the mixing channel 11 is also A stepped surface structure supporting the screen group 2 is provided;

[0062] The screen group 2 is arranged in the mud washing cylinder 1 from top to bottom; the screen group 2 has two sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com