Reactor pressure vessel main sealing surface measuring device

A technology for pressure vessels and main seals, which is applied in the field of measurement devices for the main seal surface of reactor pressure vessels, and can solve problems such as foreign objects, errors in measurement results, and high physical exertion of personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

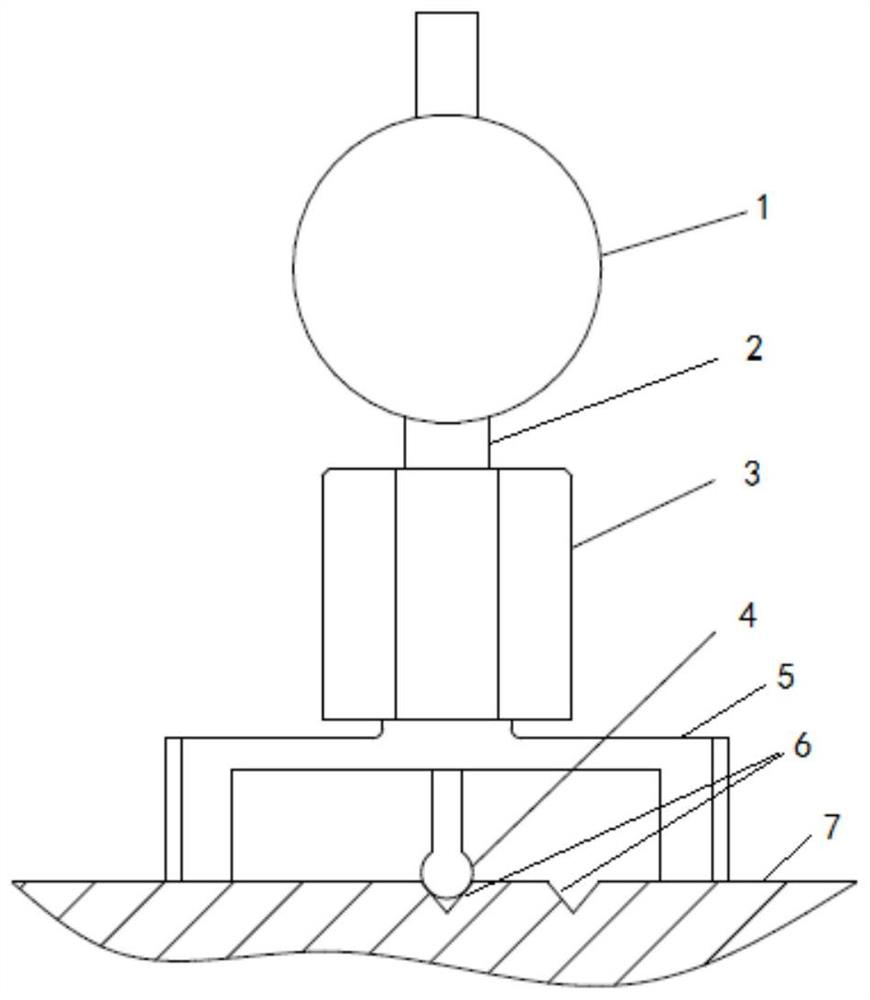

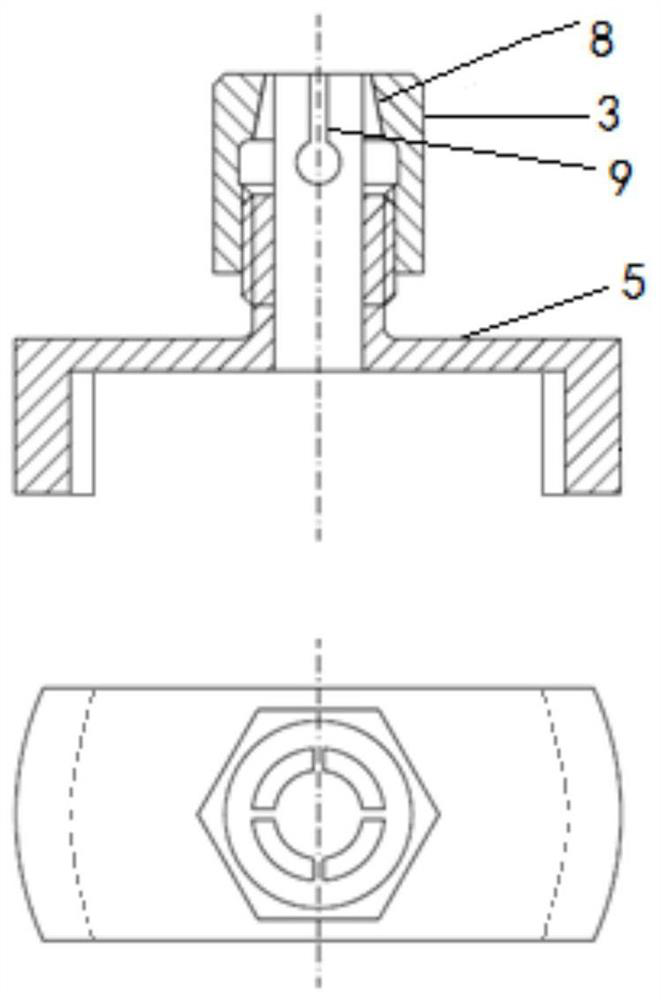

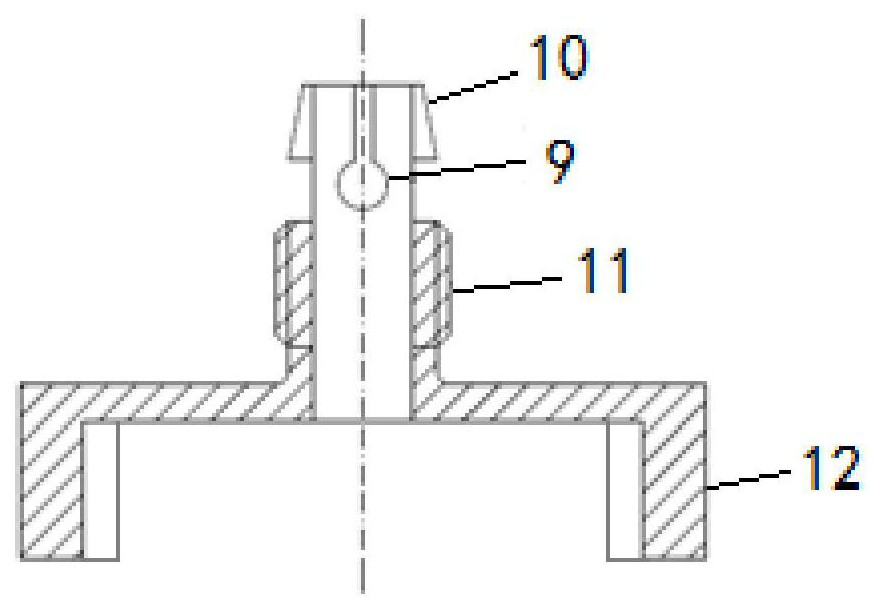

[0031] Such as figure 1 As shown, a device for measuring the main sealing surface of a reactor pressure vessel provided by the present invention includes: a measuring instrument 1, a measuring instrument fixing rod 2, a lock nut 3, a retractable measuring gauge head 4 and a support seat 5; the bottom of the measuring instrument 1 Connected with a telescopic measuring meter head 4, the measuring instrument 1 is fixedly connected to the upper part of the measuring instrument fixing rod 2; the lock nut 3 is sleeved on the support base 5, and the lock nut 3 and the support base 5 can be adjusted and connected; the measuring instrument is fixed The bottom of bar 2 is located at support seat 5 inside, measuring instrument fixed bar 2 is fixedly connected with support seat 5 by lock nut 3, and telescopic measuring meter head 4 stretches out from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com