Device and method for simultaneously detecting positioning precision and straightness of linear displacement table

A technology of positioning accuracy and linear displacement, which can be used in measurement devices, optical devices, instruments, etc., and can solve the problems of high price and high measurement cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

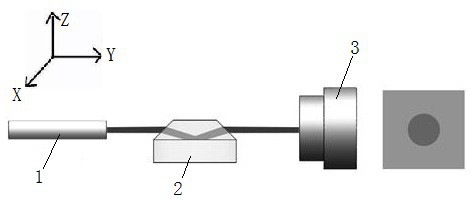

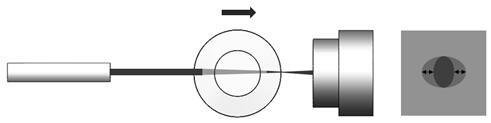

[0034] Such as figure 1 As shown, a device for simultaneously detecting the positioning accuracy and straightness of a linear displacement stage is characterized in that it includes a laser 1, a circular platform lens 2 and a CCD camera 3 that are linearly distributed sequentially, wherein:

[0035] The upper and lower end surfaces of the circular table lens are equipped with reflective films. The circular table lens is fixed on the worktable of the linear displacement stage. The positions of the laser and the CCD camera are fixed. The beam emitted by the laser is refracted through the inclined surface of the circular table lens, and the refracted beam reaches the circular table. Reflection occurs on the lower surface of the lens, and the reflected beam reaches the back of the truncated lens to be refracted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com