Basic module for building and low-rise and multi-rise modular building structure system

A basic module and construction technology, applied in the direction of buildings, building types, special buildings, etc., can solve the problem of small wet work volume, achieve the effect of small wet work volume, convenient transportation, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

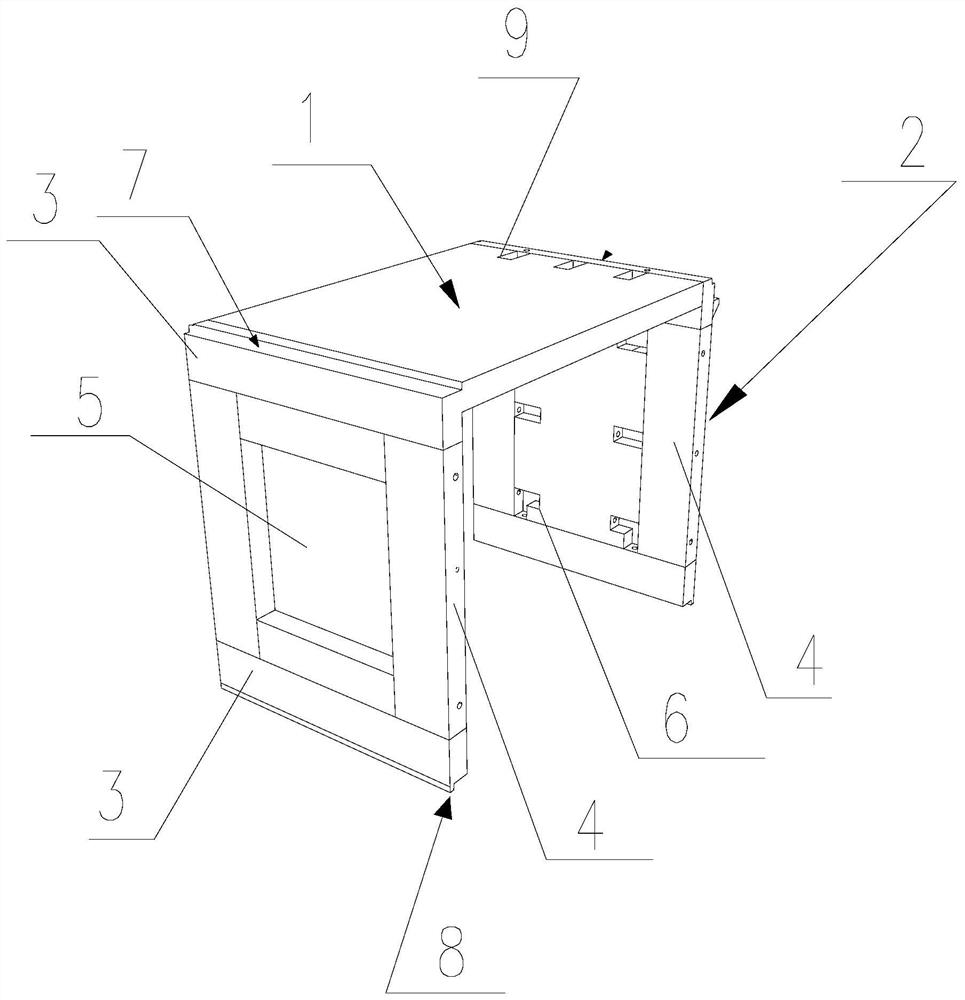

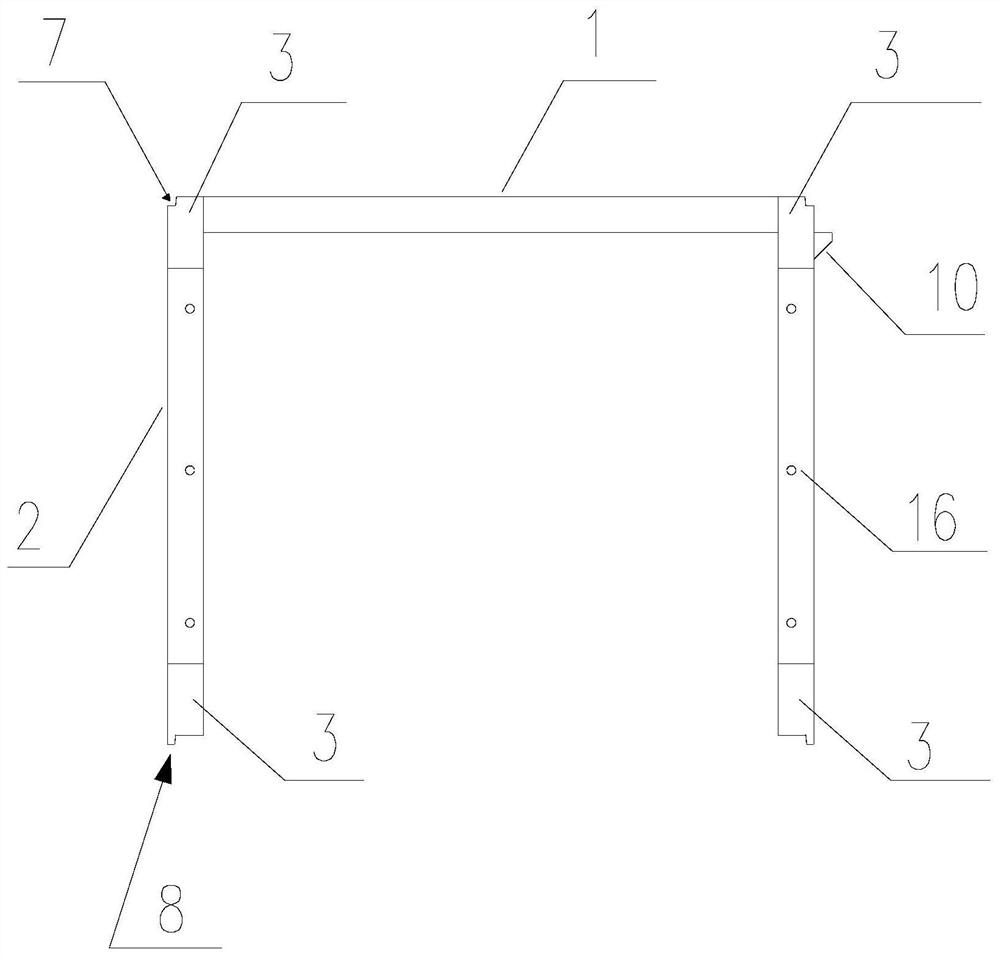

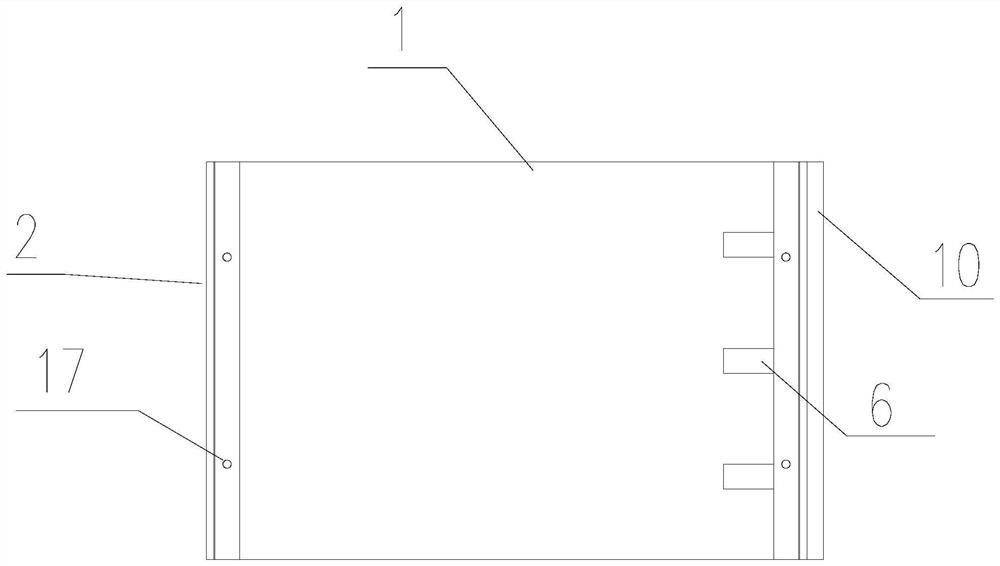

[0041] See attached figure 1 to attach Figure 4 For illustration, this embodiment 1 is a basic module for building, including an integrally formed top plate 1 and two side plates 2, and the two side plates 2 are respectively connected with the two sides of the top plate 1 to form a concrete portal frame , the vertical sides of the two side panels 2 are provided with concealed columns 4, the top and bottom sides of the two side panels 2 are provided with concealed beams 3, and the two sides of the top panel 1 are connected with the two side panels respectively. The hidden beam 3 on the top side of the side plate 2 is connected; at least one hidden column 4 of the side plate 2 is provided with a plurality of horizontal tunnels 16 that run through the hidden column 4 horizontally, and at least one hidden beam 3 of the side plate 2 is provided with a vertically penetrated dark column. A plurality of vertical tunnels 16 of the beam 3, a plurality of connecting grooves 6 correspon...

Embodiment 2

[0051] See attached Figure 6 For illustration, this embodiment 2 is a low, multi-storey modular building structure system, including two basic modules 01 in embodiment 1, a horizontal module 02 and an expansion connection assembly 13, and two basic modules 01 arranged at intervals They are connected together by a horizontal module 02, and the bottom sides of the two ends of the horizontal module 02 rest on the supporting brackets 10 of the two basic modules 01; Two installation slots (not marked in the figure), the expansion connection assembly 13 is fixed in the first installation slot 9 of the top plate 1 and the second installation slot of the horizontal module 02 for connecting the horizontal module 02 and the two basic modules 01. The vertical load transmission between the horizontal module 02 and the basic module 01 is realized through the supporting corbel 10 , and the horizontal force transmission between the horizontal module 02 and the basic module 01 is realized th...

Embodiment 3

[0061] See attached Figure 7 to attach Figure 10To illustrate, this embodiment 3 is a low, multi-storey modular building structure system, including a low, multi-storey building formed by assembling multiple sets of basic modules 01 and horizontal modules 02 in embodiment 2, wherein the same layer of building structure Among them, the two basic modules 01 arranged at intervals are connected together through the horizontal module 02 (for the specific connection structure, refer to the detailed description in Embodiment 2); The connection assembly 14 is connected together (that is, the long sides of the top boards 1 of the two basic modules 01 are tightly fitted together), and the horizontal connection assembly 14 is fixed on the connection between the two side plates 2 of the adjacent two basic modules 01. In slot 6, connect two adjacent basic modules 01 together. In the upper and lower two-story building structure, the two vertical basic modules 01 are connected together t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com