Acrylic fiber leveling agent and preparation method thereof

A technology of acrylic fiber and leveling agent, applied in dyeing method, textile and papermaking, etc., can solve the problems of not meeting finished product requirements, non-conforming production raw materials, defective finished products, etc., saving time, highlighting dyeing effect, Short production time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

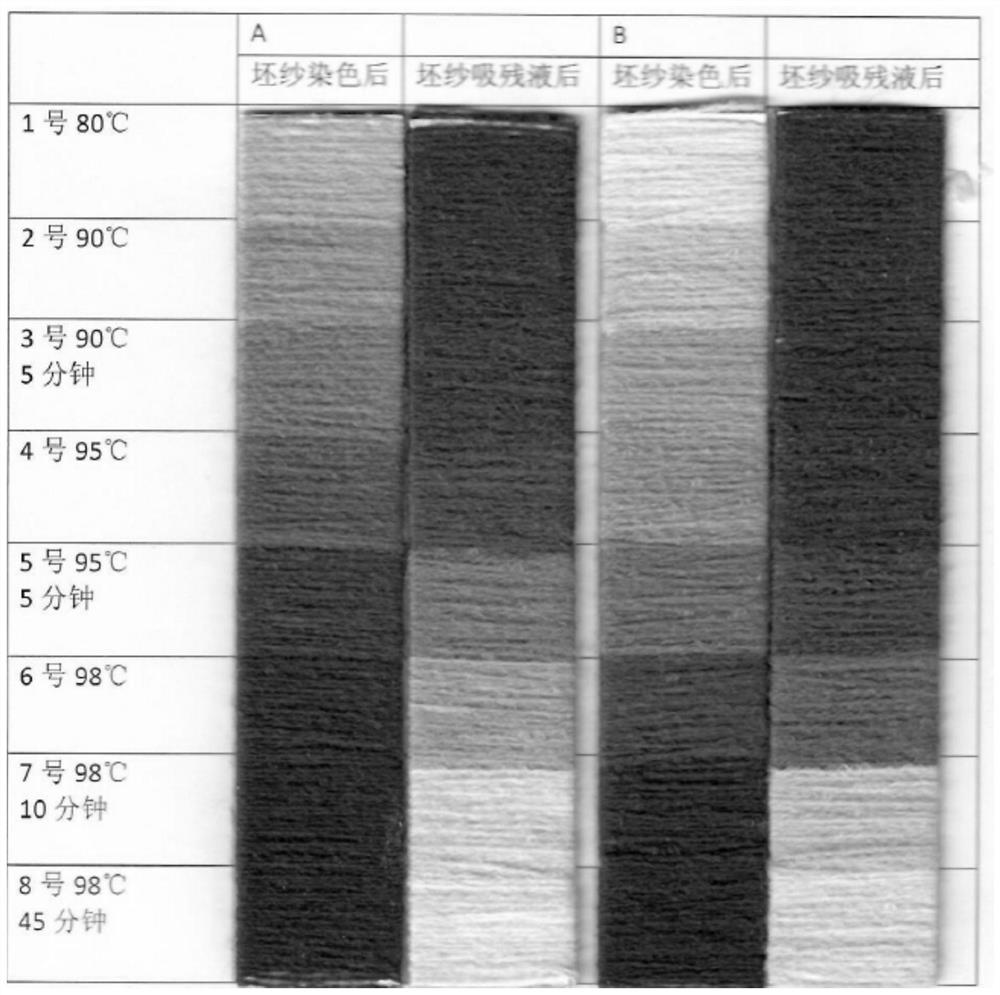

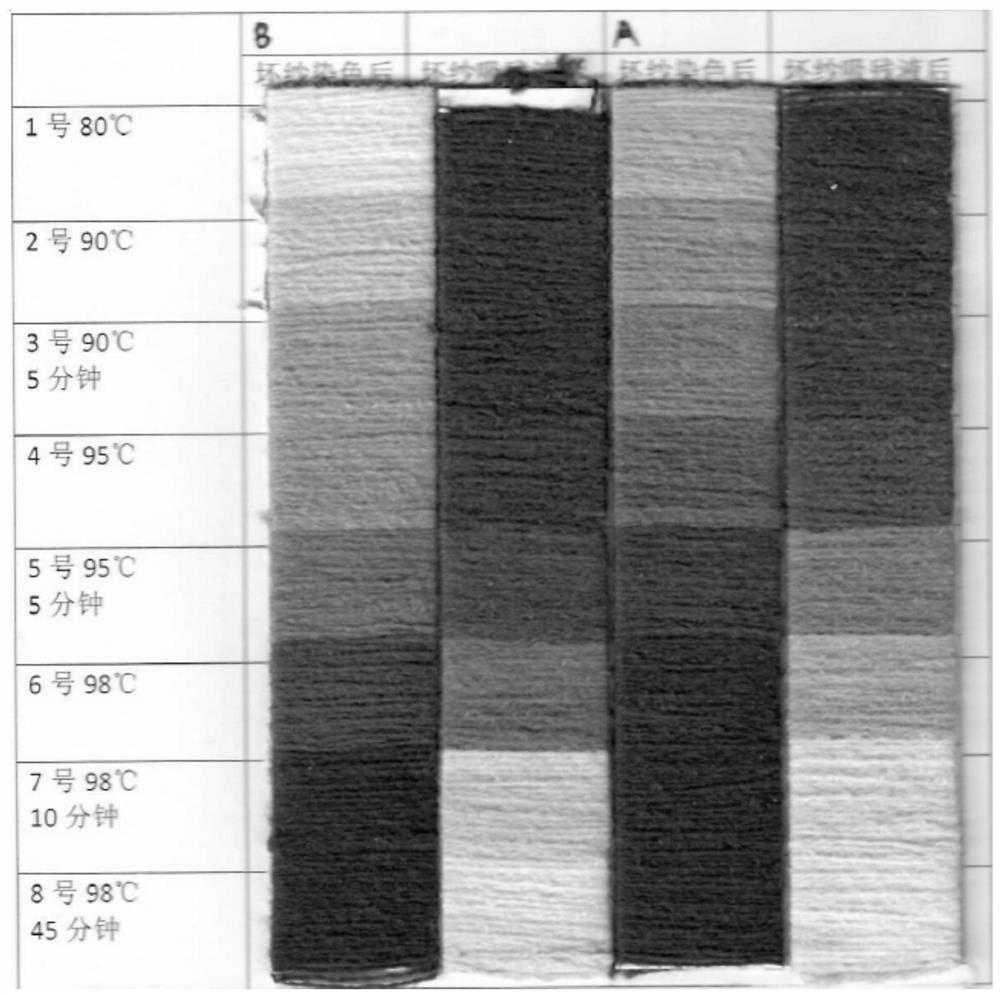

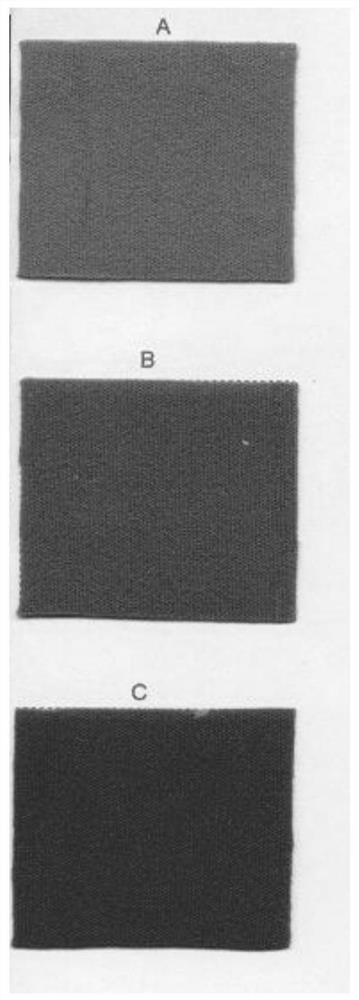

Image

Examples

preparation example Construction

[0040] A preparation method of acrylic fiber leveling agent, comprising the following steps:

[0041] (1) In a vacuum reaction kettle with a reflux cooler, first add the water in the formula to the reaction kettle, then start stirring at a stirring speed of 100rpm, and then add pyridine and its derivatives, benzyl compounds, and fatty amines in sequence And its derivatives, the reaction temperature rises from normal temperature to 55-60°C, when the temperature reaches 55-60°C, the reaction temperature will rise, and it will take 17-20 minutes for the temperature to rise to 75-80°C, from 80-110°C It takes 5 minutes, and then turn on the reflux condensed water to control the reaction, the reaction will automatically heat up to 90-110 degrees, and the vacuum insulation reaction will be 3 hours, and the product quality will be tested;

[0042] (2) When the temperature of the product in step (1) is lowered to 50°C, an emulsifier is added to react for 2 hours, and then fatty alcohol...

Embodiment 1

[0050] The invention provides an acrylic fiber leveling agent, which comprises the following components calculated by mass percentage: 15.0% picoline, 28.0% benzyl ammonium chloride, 1.0% AEO9, 7 1.0% tridecyl alcohol polyoxyethylene ether %, fatty amine polyoxyethylene ether 15 5.0%, glycerol 1.0%, water 49.0%.

Embodiment 2

[0052] The invention provides an acrylic fiber leveling agent, which comprises the following components calculated by mass percentage: picoline 28.0%, benzyltriethylammonium chloride 35.0%, TWeen80 1.0%, isomeric tridecanol polyoxyethylene Ether 7 0.5%, fatty amine polyoxyethylene ether 15 3.0%, fatty amine polyoxyethylene ether 10 2.0%, PEG400 2.0%, water 28.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com