Detachable double-layer container

A split-type, double-layer technology, applied in the field of tableware, can solve problems such as poor heat insulation effect, achieve the effect of preventing burns, good heat insulation effect, and easy to carry and use when going out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

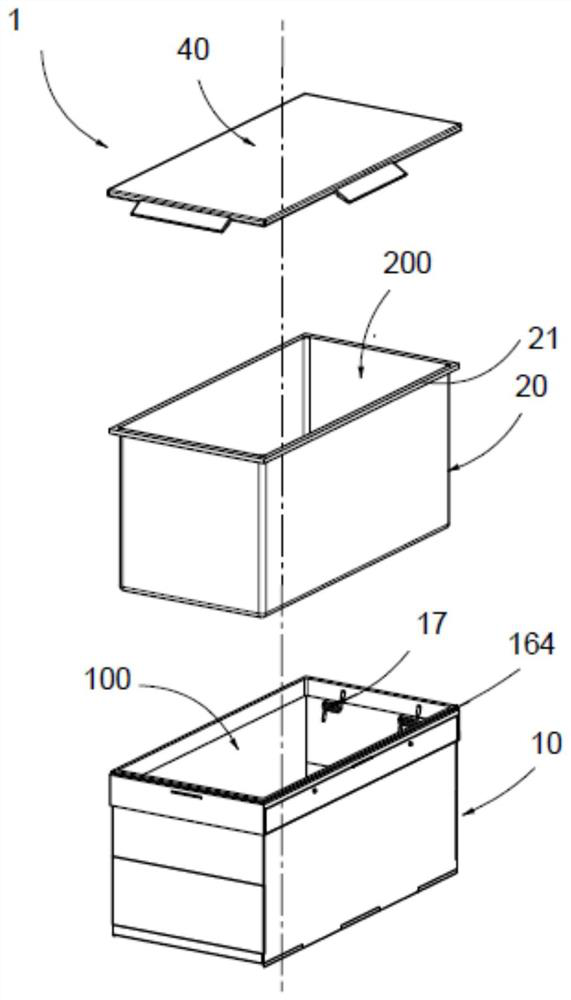

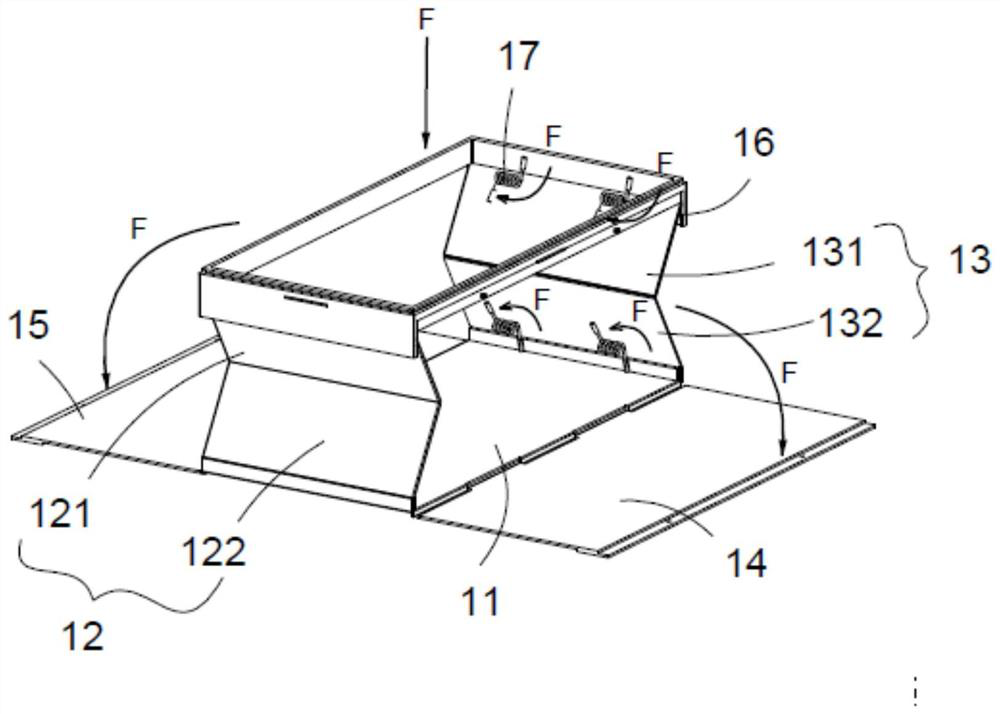

[0073] Please refer to 3A-1 to Figure 3C , the outer layer structure 10 of the present invention has an outer cavity bottom 11, a left side outer cavity wall 12, a right side outer cavity wall 13, a front side outer cavity wall 14, a rear side outer cavity wall 15, and a top layer The outer frame body 16, wherein, the left side outer cavity wall 12 and the right side outer cavity wall 13 are arranged oppositely, and the bottom ends of the left side outer cavity wall 12 and the right side outer cavity wall 13 are respectively connected to the outer cavity bottom 11, and the left side The tops of the outer cavity wall 12 and the right outer cavity wall 13 are respectively connected to the top outer frame body 16 . Furthermore, the front side external cavity wall 14 and the rear side external cavity wall 15 are set oppositely, and the bottom ends of the front side external cavity wall 14 and the rear side external cavity wall 15 are respectively connected to the bottom of the ex...

Embodiment 2

[0082] read on Figure 4 , Figure 5A and Figure 5B , in another embodiment shown as a detachable double-layer container 1, the upper left plate body 121 and the lower left plate body 122 constituting the left outer cavity wall 12 can be further bent respectively, and at the same time, the upper left plate body 122 constituting the right outer cavity wall The upper right plate body 131 and the lower right plate body 132 of the cavity wall 13 can also be further bent respectively, compared with Figure 3A-1 to Figure 3C In the illustrated embodiment, the structural design of this embodiment can further increase the size of the accommodating space of the outer cavity 100 formed when the outer layer structure 10 is in the second use state (ie the use state).

[0083] In addition, in order to make the outer layer structure 10 of the above-mentioned design structure stronger when it is in the second use state, in this embodiment, the outer layer structure 10 also has at least on...

Embodiment 3

[0093] see Figure 8A to Figure 8F As shown, it is a schematic diagram of another embodiment of the detachable double-layer container 1 . Such as Figure 8A to Figure 8F As shown, the detachable double-layer container 1 is also made up of an outer layer structure 10 and an inner layer structure 20, wherein the outer layer structure 10 has an outer cavity bottom 11, a support structure 19 (see Figure 8B ), a left side outer cavity wall 12, a right side outer cavity wall 13, a front side outer cavity wall 14, a rear side outer cavity wall 15, and a top floor outer frame body 16, and the left side outer cavity wall 12 and The right side outer cavity wall 13 is oppositely arranged, the bottom ends of the left side outer cavity wall 12 and the right side outer cavity wall 13 are respectively connected to the opposite sides of the outer cavity bottom 11, the left side outer cavity wall 12 and the right side outer cavity wall 13 The tops of the tops are respectively connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com