Efficient recycling and transferring equipment for new energy automobile battery

A new energy vehicle and battery technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve problems such as unfavorable use, erosion, time delay, etc., and achieve the effect of easy reversing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

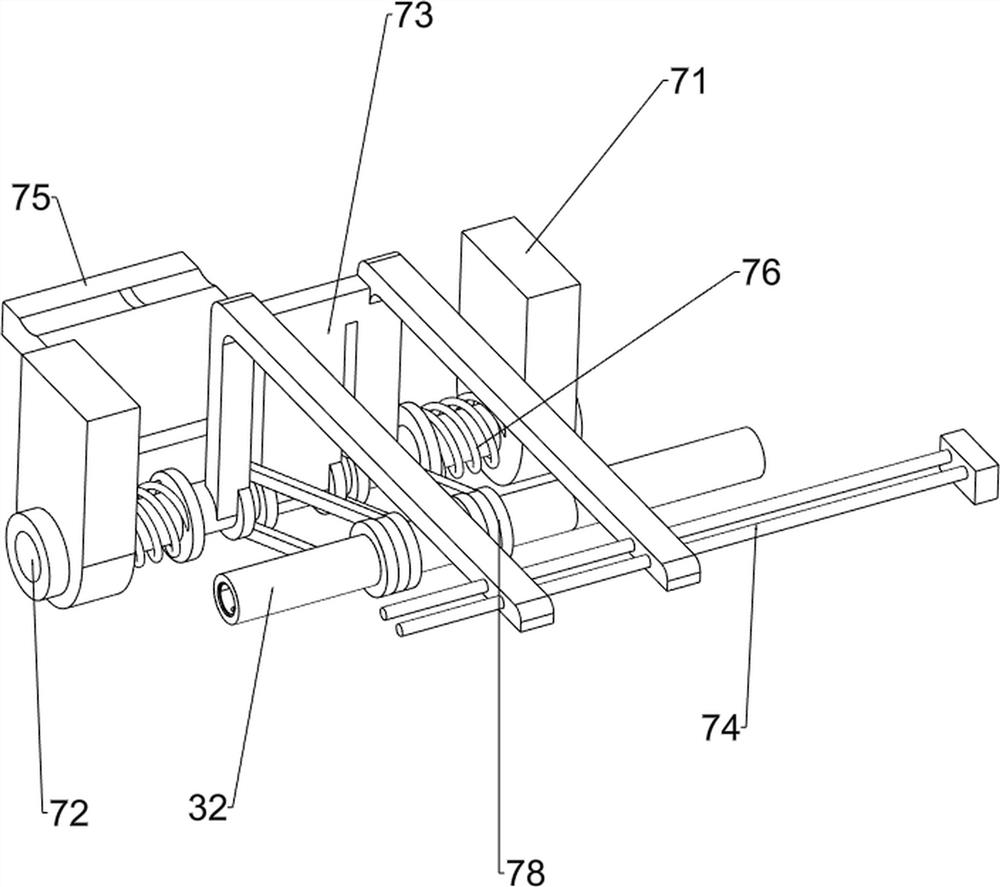

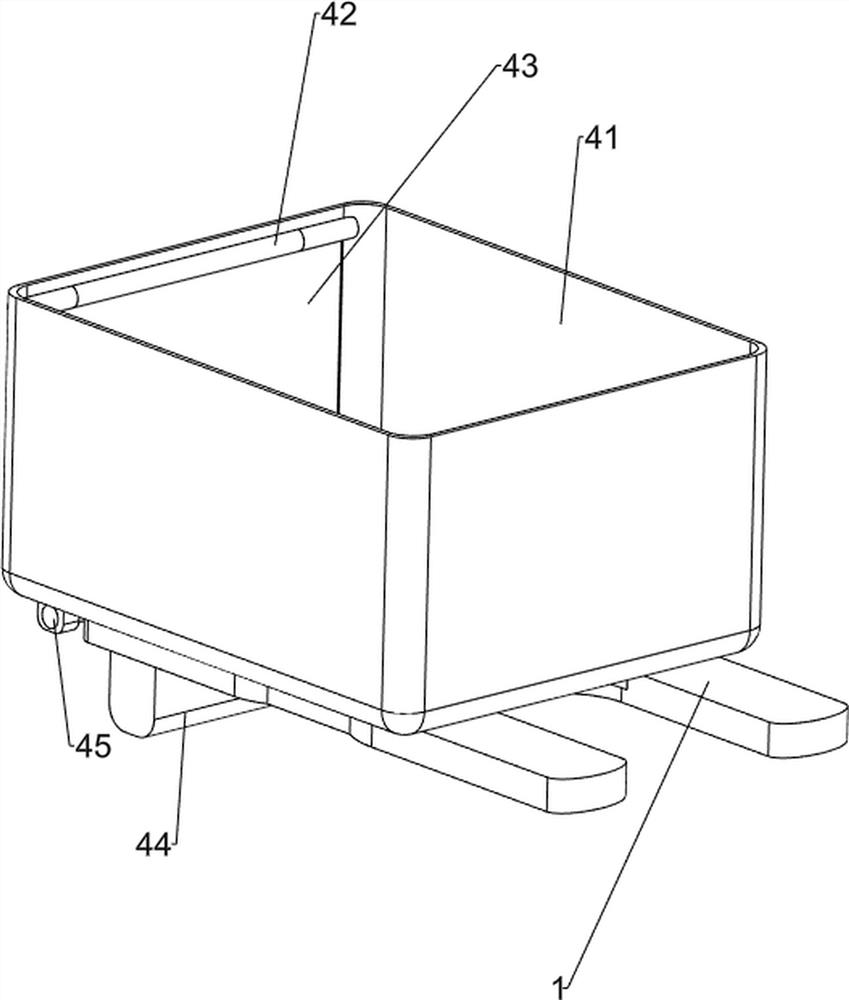

[0029] A new energy vehicle battery efficient recycling and transshipment equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom plate 1, a connecting ring 2, a moving mechanism 3 and a material holding mechanism 4. Both sides of the bottom of the bottom plate 1 are provided with connecting rings 2, and the bottom of the bottom plate 1 is provided with a moving mechanism 3. The moving mechanism 3 and the connecting ring 2 Connection, the bottom plate 1 is provided with a filling mechanism 4.

[0030] When people need to transfer the recovered new energy vehicle batteries, first people pour the recovered new energy vehicle batteries into the material holding mechanism 4, and then make the moving mechanism 3 operate, and the moving mechanism 3 operates to move the bottom plate 1, and then the container The charging mechanism 4 moves, so that the battery moves, and at the same time, people manually control the moving direction of the bottom plate 1....

Embodiment 2

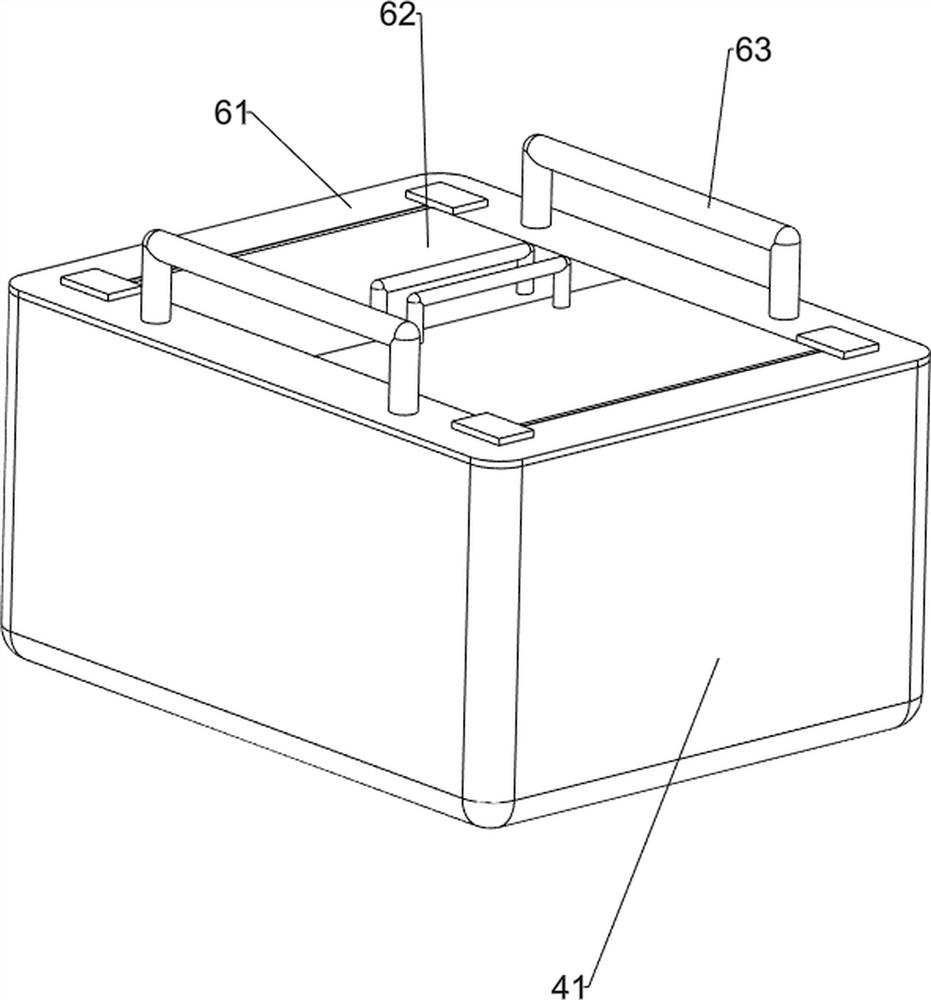

[0036] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 Shown, also comprise steering mechanism 5, steering mechanism 5 includes pedal 51, long connecting rod 52, steering wheel 53, high fixed frame 54, positioning collar 55, reversing gear 56 and hand-held ring 57, Base plate 1 front portion inboard is provided with pedal 51, and pedal 51 top side rear portion is provided with high fixed frame 54, is connected with long connecting rod 52 between high fixed frame 54 inboard and pedal 51 inboards, and long connecting rod 52 bottom left and right sides are all rotatable and are provided with steering wheel 53, and long connecting rod 52 front side tops are rotatably provided with positioning collar 55, and on the locating collar 55 and long connecting rod 52 tops, all are provided with reversing gear 56, front and rear The reversing gears 56 on both sides mesh with each other, and the front part of the positioning col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com