Prefabricated stand column humidifying and maintaining device and adjusting method thereof

An adjustment method and column technology, applied in the field of construction engineering, can solve the problems of low work efficiency, uncontrollable artificial spraying, inability to prefabricate column spraying and watering, etc., and achieve the effect of improving maintenance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

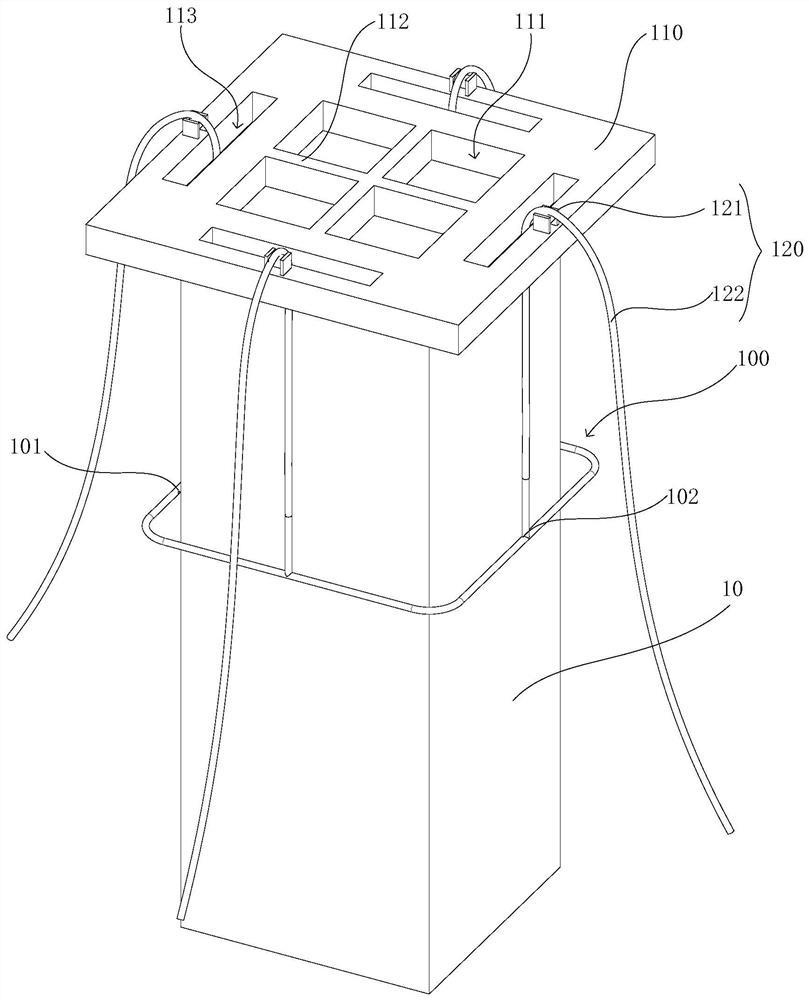

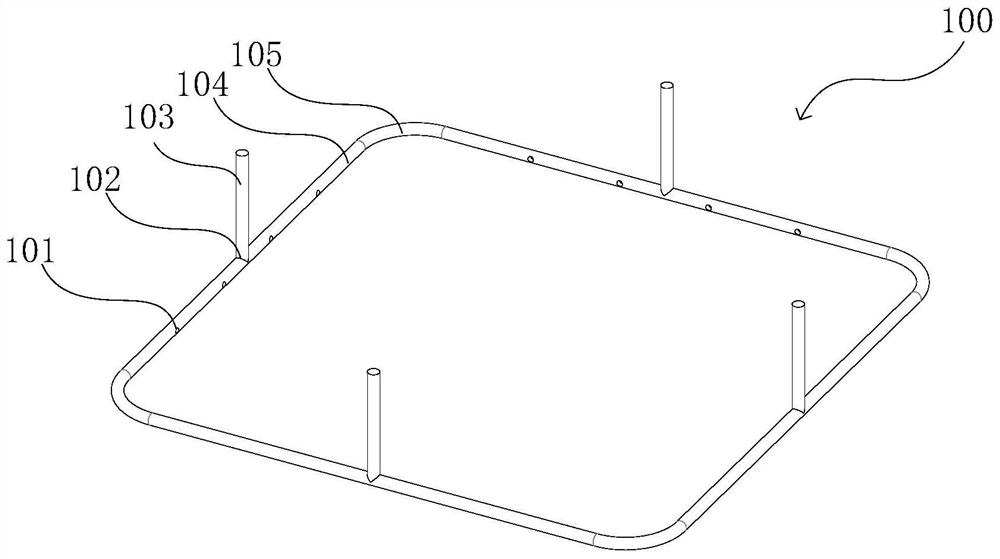

[0039] see figure 1 , which is a structural schematic diagram of a prefabricated column humidification and maintenance device provided in the first embodiment of the present invention. The prefabricated column humidification and maintenance device includes, for example: an installation platform 110 , a lifting assembly 120 and a maintenance water pipe 100 . Wherein, the installation platform 110 is installed on the top of the prefabricated column 10 to be maintained; each lifting assembly 120 is respectively wound around the installation platform 110; one end of each lifting assembly 120 is connected to the maintenance water pipe 100 .

[0040] Specifically, the installation platform 110 includes, for example: a reinforcement installation groove 111, the reinforcement installation groove 111 is arranged in the middle of the installation platform 110, the reinforcement installation groove 111 is a through groove through the installation platform 110, so that The top of the upri...

Embodiment 2

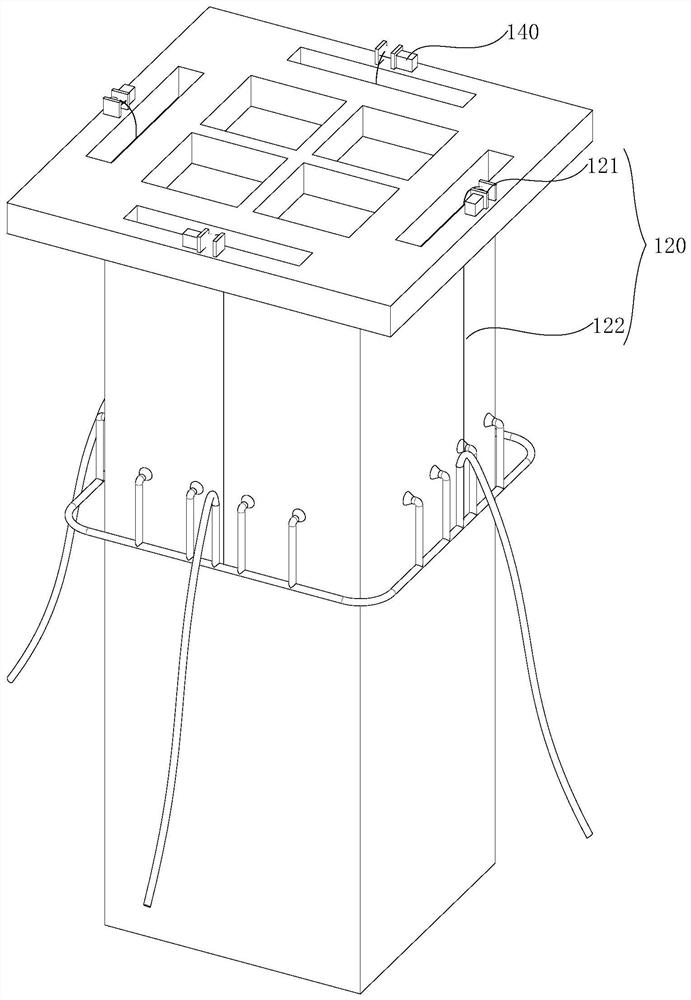

[0052] see image 3 , which is a structural schematic diagram of another prefabricated column humidification and maintenance device provided in the second embodiment of the present invention. The lifting member 122 in the assembly 120 is a lifting rope; the driving motor 140 is connected to the lifting assembly 120 by a shaft.

[0053] Specifically, the lifting assembly 120 is composed of a rotating member 121 and a lifting rope wound on the rotating member 121;

[0054] Preferably, in order to prevent the maintenance water pipe 100 from shaking during the lifting process, thereby colliding with the upright column 10 to be maintained, the lifting rope can be a hard rope with a certain strength such as a steel wire rope, which is not limited here.

[0055] Further, the lifting assembly 120 also includes a drive motor 140, the drive motor 140 is connected to the rotating member 121, and controls the rotating member 121 to rotate forward or reversely, so as to change the length ...

Embodiment 3

[0057] see Figure 4 , which is a structural schematic diagram of another prefabricated column humidification and curing device provided in the third embodiment of the present invention. The prefabricated column humidification and curing device is similar to the prefabricated column humidification and curing device provided in the first embodiment or the second embodiment. The advantage is that the lifting assembly 120 is a retractable hydraulic component.

[0058] Specifically, the telescopic hydraulic part is arranged around the installation platform 110, one end of the telescopic hydraulic part is connected to the side of the installation platform 110 close to the top of the prefabricated column 10 to be maintained, and the opposite end is connected to the maintenance water pipe 100 ; By controlling the telescopic length of the telescopic hydraulic parts, and then controlling the lifting of the maintenance water pipe 100, changing the position of the maintenance water pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com