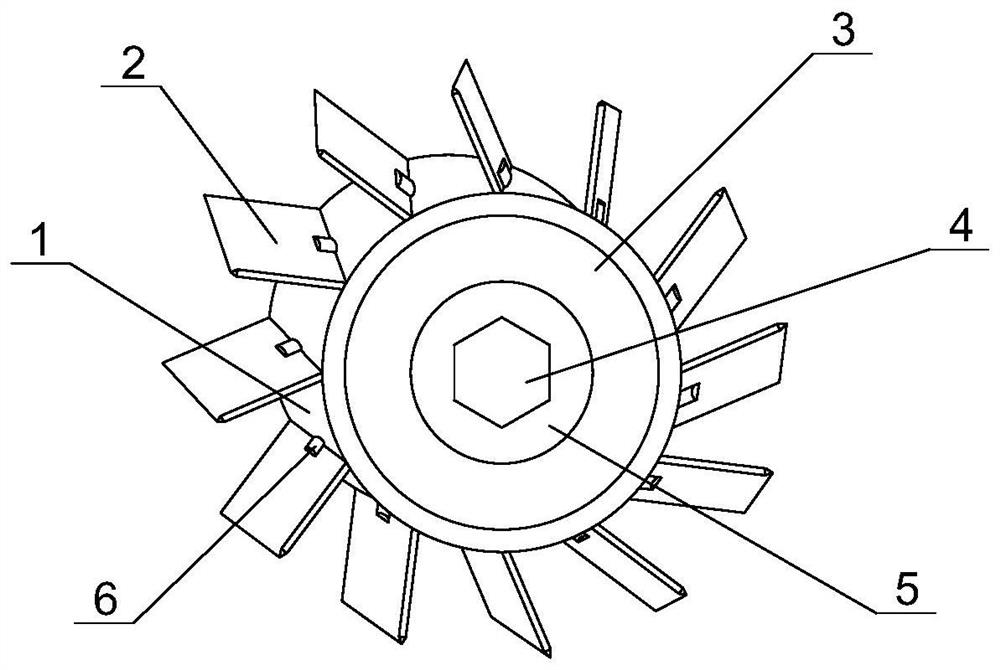

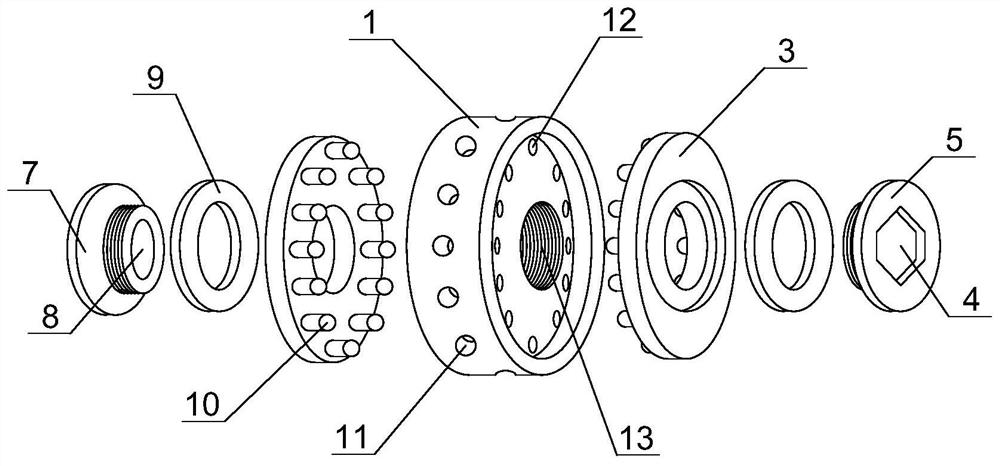

Axial flow fan impeller

An axial flow fan and impeller technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as improving efficiency, inability to adjust the number of blades, and easily scratching staff, and achieve the effect of ensuring normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

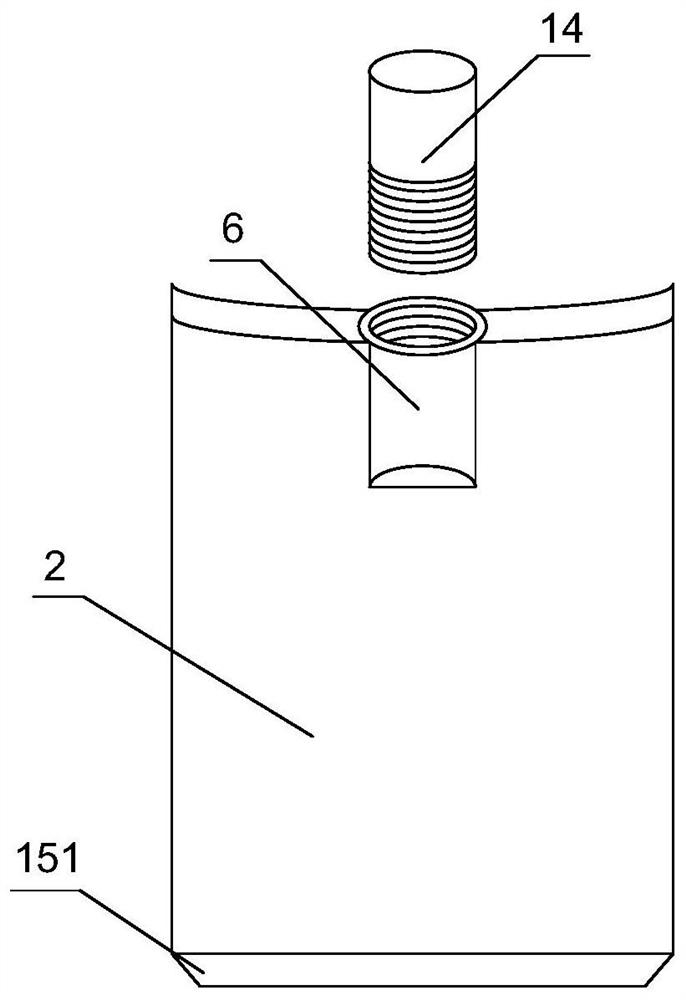

[0028] As a specific embodiment of the present invention, the anti-scratch unit 15 includes a hollow nylon layer 151, the hollow nylon layer 151 is fixed to the edge of the blade 2, and the end of the hollow nylon layer 151 away from the blade 2 is sharp; The nylon layer 151 is filled with a magneto-rheological fluid 152; the interior of the blade 2 is filled with an electromagnet 153, and the electromagnet 153 is energized to change the fluidity of the magnetorheological fluid 152;

[0029] When the axial flow fan is working, the electromagnet 153 can be energized to form a magnetic field in the blade 2, so that the magnetorheological fluid 152 in the hollow nylon layer 151 presents the characteristics of high viscosity and low fluidity, so that the hollow nylon layer 151 The filling is tight, and the end of the hollow nylon layer 151 away from the blade 2 is sharp, so as to prevent the hollow nylon layer 151 from affecting the rotation speed of the blade 2, resulting in a red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com