Automatic stirring non-clogging sludge pump

An automatic mixing and non-clogging technology, which is applied in the field of sofas, can solve problems such as low production and assembly efficiency, weak cutting ability, and complicated assembly, and achieve the effects of saving installation and processing costs, easy maintenance and repair, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

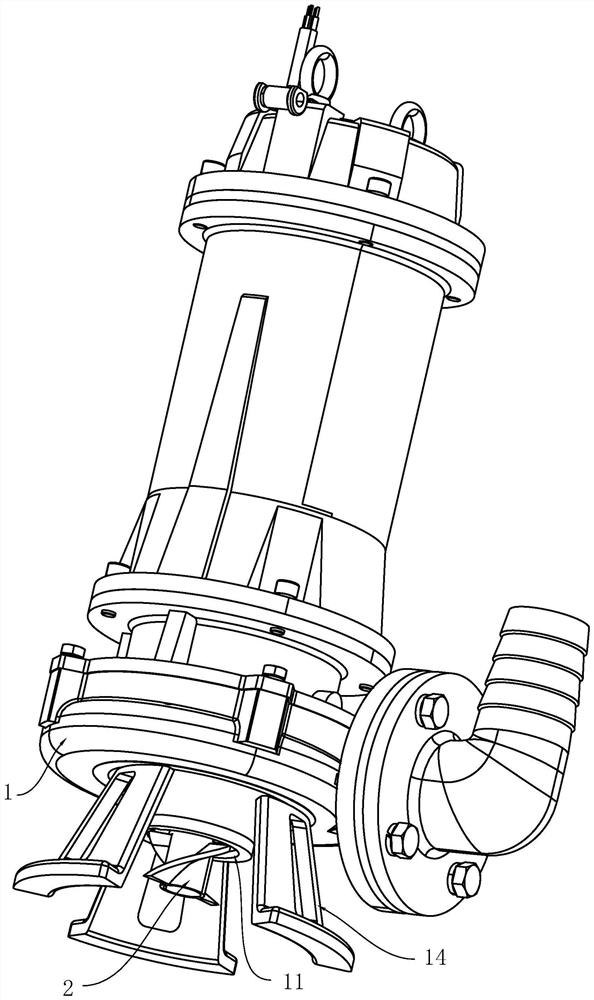

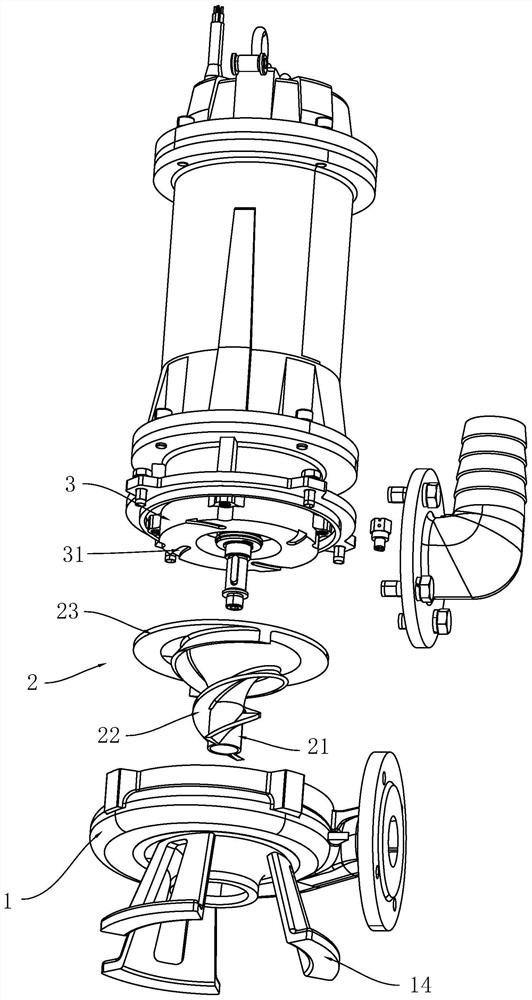

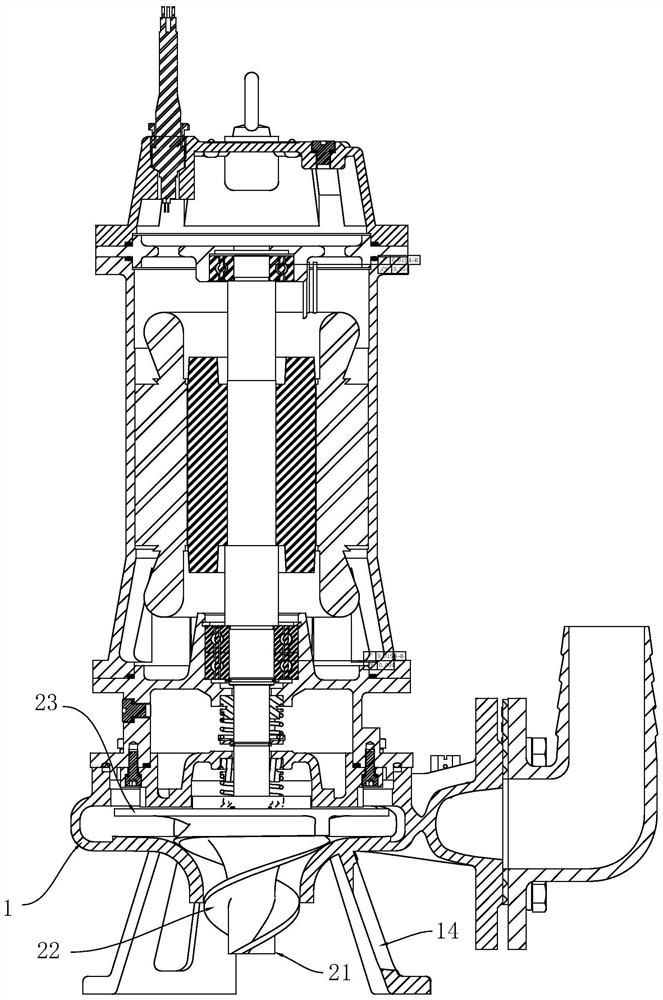

[0019] Example: Figure 1-4 As shown, the automatic stirring is not blocked and the slurry pump, including the pump body 1, the impeller 2 provided in the pump body, the pump body is opened, and the water pump is disposed in the axis of the pump body. The corresponding position is provided at the radial direction of the pump body, the hub 21 of the impeller being tapered, the hub, the hub, the hub, the water, and in the housing The outer extension has an extension, the blade of the impeller is a helical centrifugal blade 22, which extends from one end spiral trail of the hub to the other end of the hub, the blade extends outside of the housing. segment. The special structure of the impeller can form an extension section outside the pump body, and the extension segment forms agitating the impeller effect, reaching the purpose of stirring the mud, sed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com