Connecting structure and method for integrated profile steel and cross beam

A technology of integrated section steel and connection structure, which is applied in the direction of building structure and construction, can solve the problems of reduced reliability, heavy welding workload on site, and low construction efficiency, so as to reduce the difficulty of assembly, save welding operations, reduce The effect of connection gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

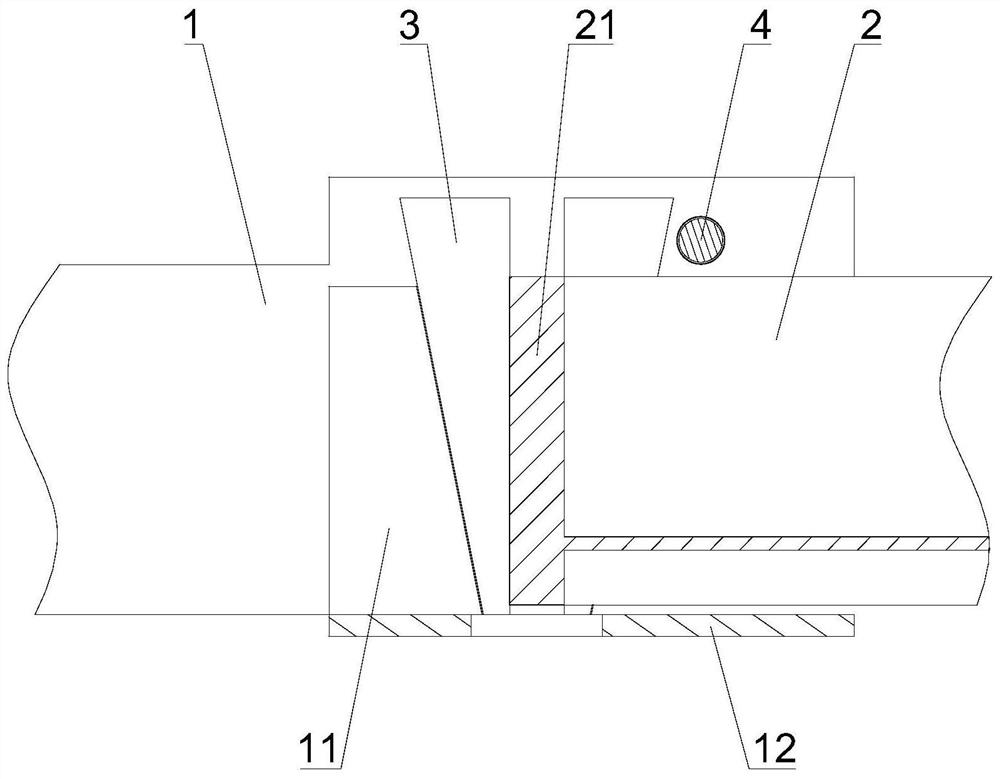

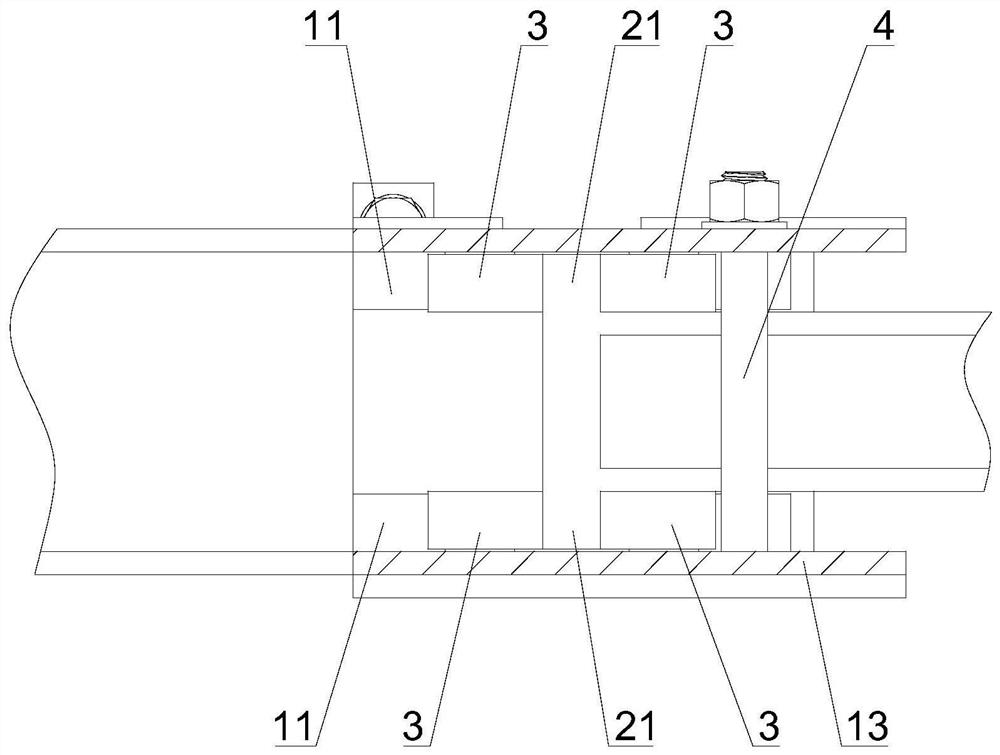

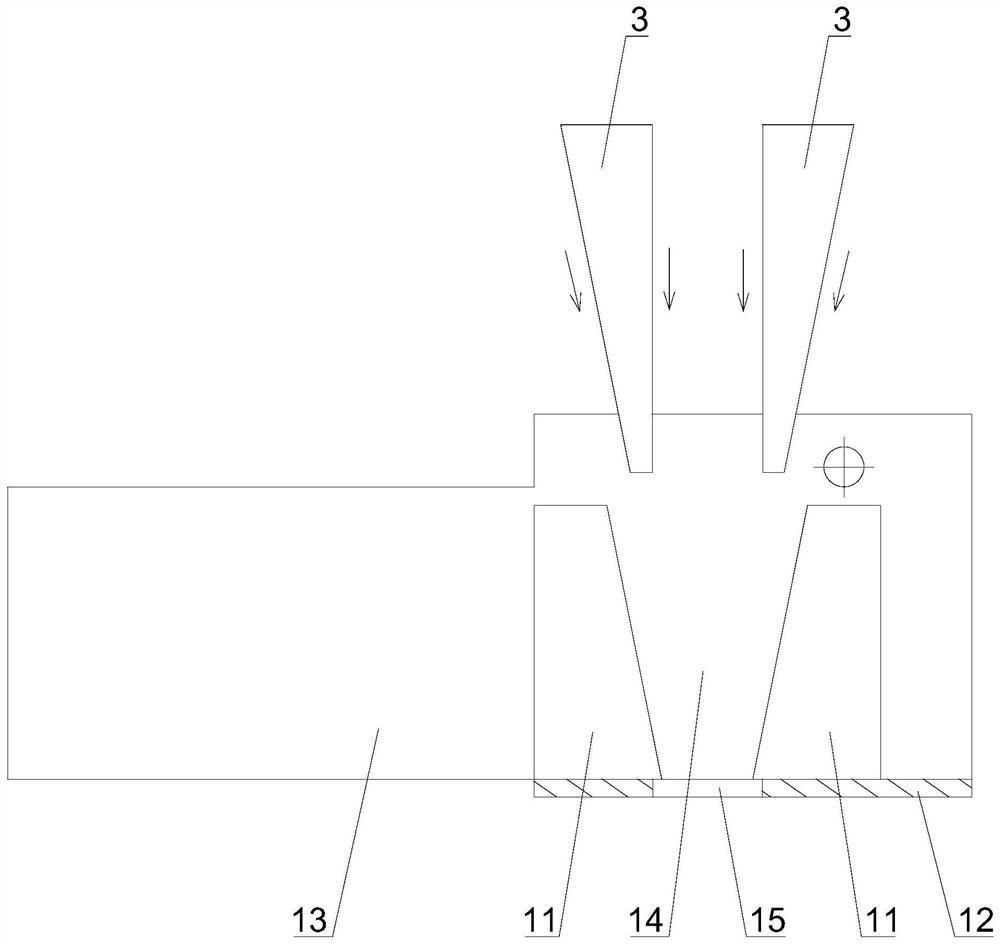

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] see Figures 1 to 4 As shown, this embodiment provides a connection structure between an integrated steel profile and a crossbeam, which includes an interface 1 provided on the integrated steel section, a tenon 2 provided at the end of the beam, and a brake iron 3 .

[0028] The edge of the end of the tenon 2 exceeds the side wall of the tenon 2 to form a limit edge 21. Specifically, the tenon 2 includes an I-beam 22 welded on the crossbeam. The end of the I-beam 22 is provided with an end plate 23, and the end plate 23 The edge forms the limiting edge 21 .

[0029] An installation cavity is formed on the interface 1, and two wedge-shaped blocks 11 are respectively arranged on both sides of the installation cavity. Specifically, the interface 1 includes a bottom plate 12 and a side plate 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com