Basic magnesium sulfate cement and preparation method thereof

A magnesium sulfate, basic technology, applied in the field of building materials, can solve the problems of prolonging the setting time, unable to speed up the setting rate of basic magnesium sulfate cement system, slow product hardening, etc., to improve the setting and hardening speed, reduce the risk of cracking, early high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present embodiment provides a kind of preparation of basic magnesium sulfate cement:

[0025] The preparation of magnesium oxysulfide crystal nucleating agent:

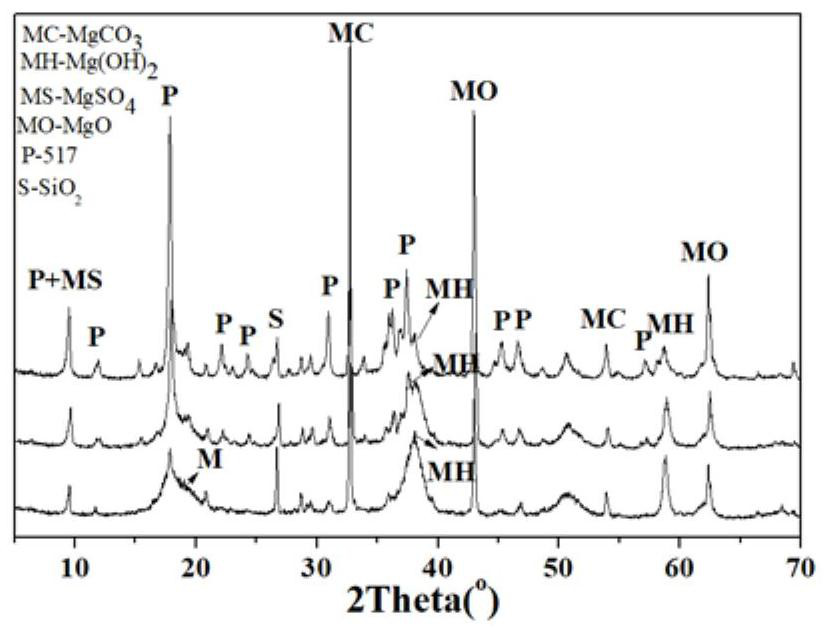

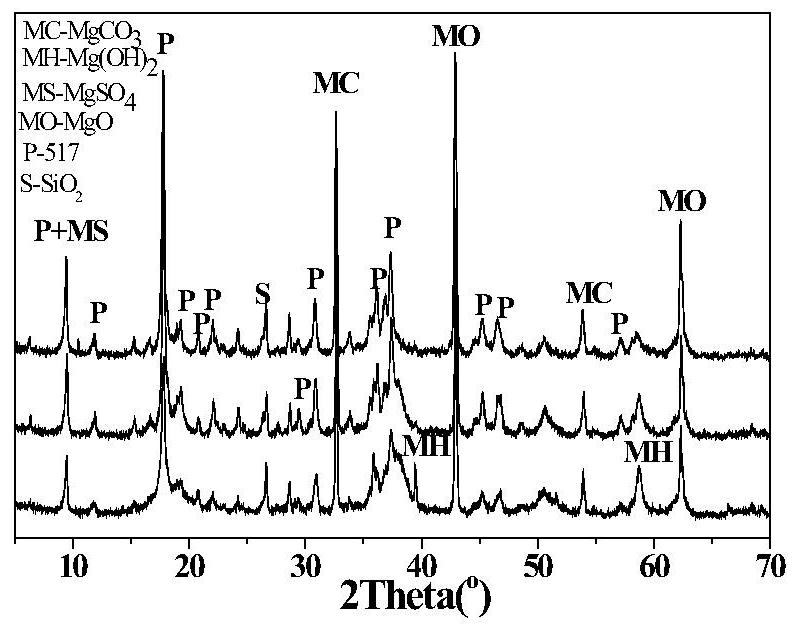

[0026] Mix 100 parts of light-burned magnesite powder with active MgO mass fraction of 55%, 0.05 part of phosphoric acid and 143 parts of magnesium sulfate solution with a mass fraction of 20%; Cure for 28 days at ℃ to accelerate hardening. Finally, the hardened sample is ground into powder by ball milling to obtain the magnesium oxysulfide crystal nucleating agent, the main composition of which is Mg(OH) 2 · MgSO 4 ·5H 2 O(1.1.5).

[0027] Preparation of basic magnesium sulfate cement:

[0028] 100 parts of active magnesium oxide powder with a mass fraction of 55% of active MgO, 0.01 part of potassium dihydrogen phosphate, and 1 part of 1.1.5 magnesium oxysulfide crystal nucleating agent are mixed and ground and passed through a 100-mesh sieve, and 100 parts of 20wt% The magnesium sulfate heptahydrat...

Embodiment 2

[0030] The present embodiment provides a kind of preparation of basic magnesium sulfate cement:

[0031] The preparation of magnesium oxysulfide crystal nucleating agent:

[0032] 100 parts of light-burned magnesite powder with active MgO mass fraction of 62%, 0.05 part of phosphoric acid and 106.2 parts of magnesium sulfate solution with mass fraction of 20% were mixed; Cure for 28 days at ℃ to accelerate hardening. Finally, the hardened sample is ground into powder by ball milling to obtain a magnesium oxysulfide crystal nucleating agent, the main composition of which is 2Mg(OH) 2 · MgSO 4 ·3H 2 O(2 1 3).

[0033] Preparation of basic magnesium sulfate cement:

[0034] 100 parts of active magnesium oxide powder with a mass fraction of 75% of active MgO, 0.03 parts of sodium dihydrogen phosphate, and 3 parts of 2.1.3 magnesium oxysulfide crystal nucleating agent were mixed and ground and passed through a 100-mesh sieve, and 94 parts of 20wt% The magnesium sulfate pentah...

Embodiment 3

[0036] The present embodiment provides a kind of preparation of basic magnesium sulfate cement:

[0037] The preparation of magnesium oxysulfide crystal nucleating agent:

[0038] Mix 100 parts of light-burned magnesite powder with an active MgO mass fraction of 68%, 0.05 parts of phosphoric acid and 300 parts of a 20% magnesium sulfate solution; Cure for 28 days at ℃ to accelerate hardening. Finally, the hardened sample is ground into powder by ball milling to obtain a magnesium oxysulfide crystal nucleating agent, the main composition of which is 3Mg(OH) 2 · MgSO 4 ·8H 2 O(3 1 8).

[0039] Preparation of basic magnesium sulfate cement:

[0040] 100 parts of active MgO mass fractions are 64% active magnesium oxide powder, 0.05 parts of ammonium dihydrogen phosphate, 5 parts of 3.1.8 magnesium sulfate crystal nucleating agent are mixed and ground and passed through a 100 mesh sieve, and 73 parts of 20wt% The magnesium sulfate trihydrate solution is mixed and hardened to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com