Recovery method for aroma components in papermaking wastewater, intercepted concentrated solution formed after implementation of recovery method and application of intercepted concentrated solution

A recovery method and concentrate technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve resource waste, unsatisfactory interception and removal effect of small and medium molecular weight organic matter, and reconstituted tobacco leaves are not considered Recycling and utilization of aroma components in the medium to achieve the effect of increasing the content of aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

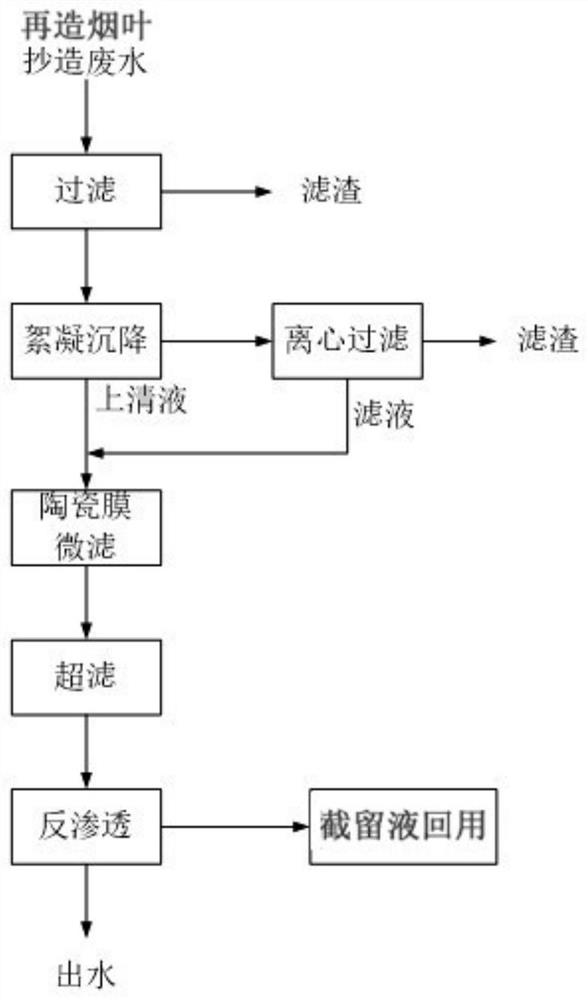

[0032] In this embodiment, a method for recovering the aroma components of the papermaking wastewater formed in the production of reconstituted tobacco leaves is provided, the steps are as follows:

[0033] 1) Filtration treatment of reconstituted tobacco leaf manufacturing wastewater: the reconstituted tobacco leaf manufacturing wastewater is filtered with a plate and frame filter to remove solid suspended matter to obtain the first filtrate;

[0034]2) Flocculation treatment: Add polyacrylamide flocculant to the first filtrate under stirring condition, the amount of polyacrylamide added is 0.15wt% of the mass of filtrate, continue stirring for 5 minutes after adding flocculant, stop stirring, flocculation and sedimentation 3 hours, release the supernatant, obtain the second filtrate after the floc at the bottom of the settling tank is filtered with a decanter centrifuge;

[0035] 3) Ceramic membrane filtration: the second filtrate and the flocculation sedimentation supernata...

Embodiment 2

[0040] In this embodiment, a method for recovering the aroma components of the papermaking wastewater formed in the production of reconstituted tobacco leaves is provided, the steps are as follows:

[0041] 1) Filtration treatment of reconstituted tobacco leaf manufacturing wastewater: the reconstituted tobacco leaf manufacturing wastewater is filtered with a plate and frame filter to remove solid suspended matter to obtain the first filtrate;

[0042] 2) Flocculation treatment: add polyacrylic acid flocculant to the first filtrate under stirring condition, the amount of polyacrylic acid added is 0.15wt% of the mass of the filtrate, continue to stir for 5 minutes after the addition of flocculant, stop stirring, flocculate and settle for 3 hours , release the supernatant, and obtain the second filtrate after filtering the flocs at the bottom of the settling tank with a decanter centrifuge;

[0043] 3) Ceramic membrane filtration: the second filtrate and the flocculation and sed...

Embodiment 3

[0048] In this embodiment, a method for recovering the aroma components of the papermaking wastewater formed in the production of reconstituted tobacco leaves is provided, the steps are as follows:

[0049] 1) Filtration treatment of reconstituted tobacco leaf manufacturing wastewater: the reconstituted tobacco leaf manufacturing wastewater is filtered with a plate and frame filter to remove solid suspended matter to obtain the first filtrate;

[0050] 2) Flocculation treatment: Add polyacrylamide flocculant to the first filtrate under stirring condition, the amount of polyacrylamide added is 0.05wt% of the mass of the filtrate, continue stirring for 5 minutes after the addition of flocculant, stop stirring, flocculation and sedimentation After 5 hours, the supernatant was released, and the floc at the bottom of the settling tank was filtered with a decanter centrifuge to obtain the second filtrate;

[0051] 3) Ceramic membrane filtration: the second filtrate and flocculation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com