Hoisting equipment for transformer installation

A technology for hoisting equipment and transformers, applied in the field of transformers, can solve problems such as offset side slip, waste of human resources, excessive staff, etc., and achieve the effect of preventing the center of gravity from drifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

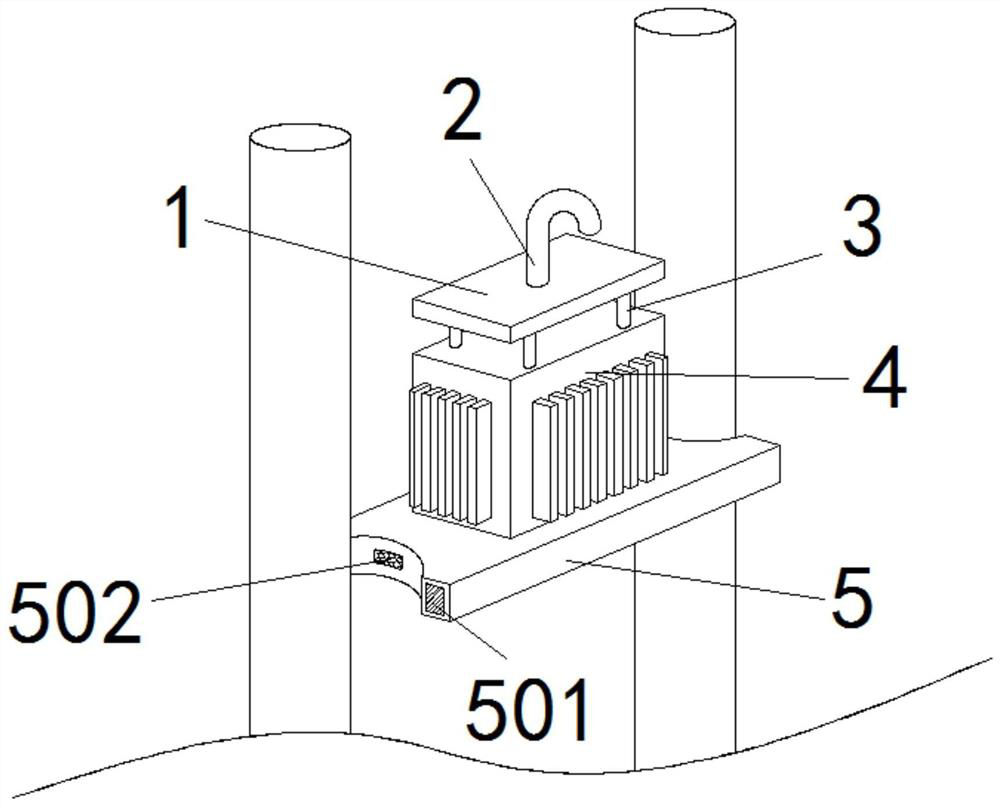

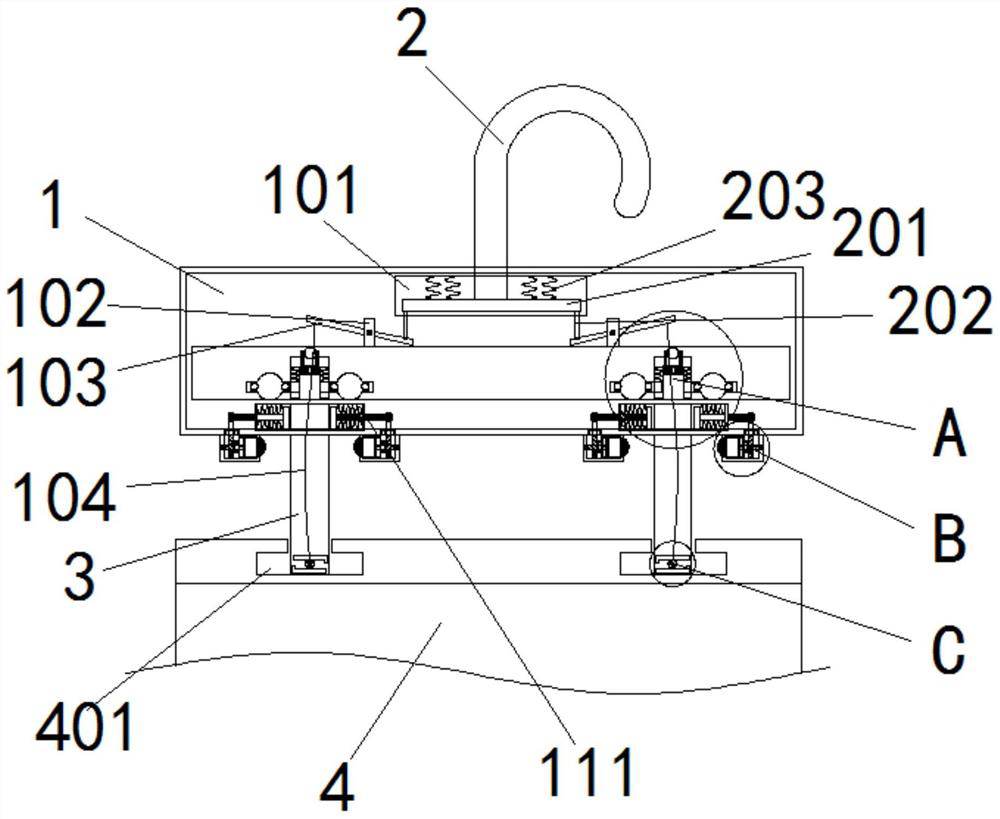

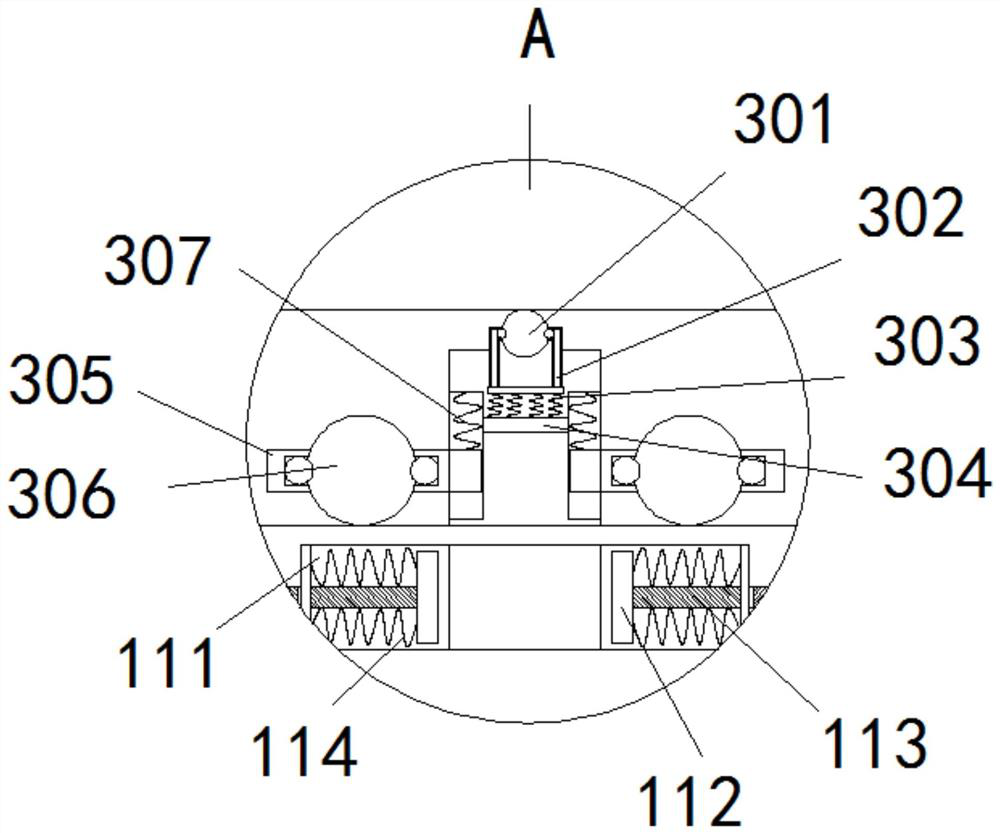

[0028] as attached figure 1 to attach Figure 7 Shown: a hoisting device for installing a transformer, including a hoisting plate 1, a hook 2, a connecting hook 3, a transformer 4, and a fixed bottom plate 5, wherein a hook limit groove 101 is opened in the center of the top of the hoisting plate 1, and the hook limit groove 101 is movably connected with a hook 2, the bottom of the hook 2 is fixedly connected with a hook base plate 201, and both sides of the bottom of the hook base plate 201 are fixedly connected with push rods 202, and the top of the hook base plate 201 and the inner top of the hook limit groove 101 are fixedly connected with a strong force. The spring 201, the bottom of the lifting plate 1 is connected with the connecting hook 3, and the bottom of the lifting plate 1 is provided with pushback device cabins 105 on both sides of the connecting hook 3, the bottom of the connecting hook 3 is engaged with the transformer 4, and the top of the transformer 4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com